A kind of anti-loosening socket

A socket and anti-loose technology, applied in the direction of the base/shell, coupling device, magnetic object, etc., can solve the problem of poor contact between the reed and the plug, and achieve the effect of preventing poor contact and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

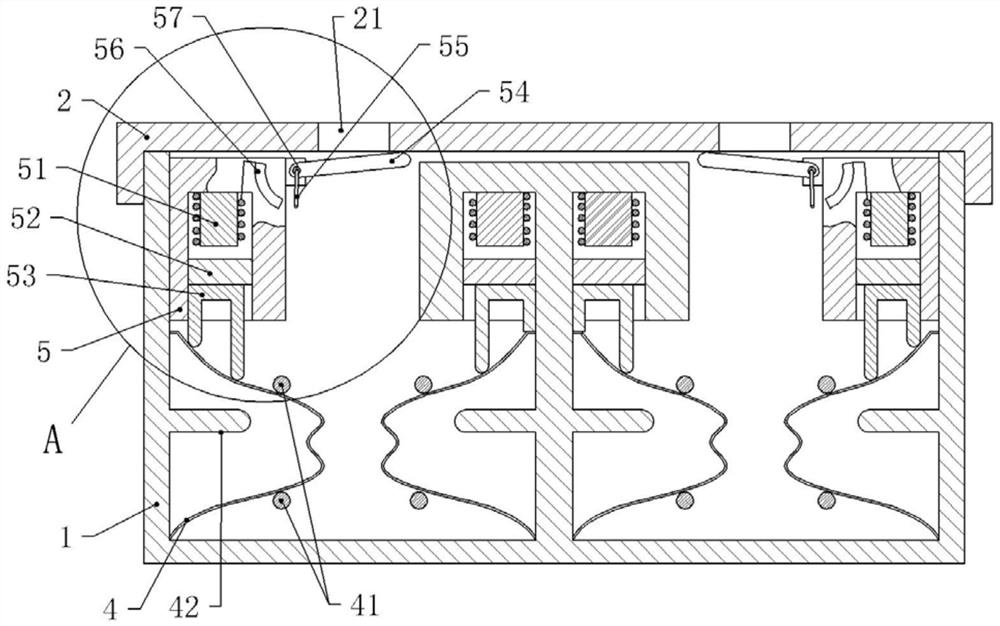

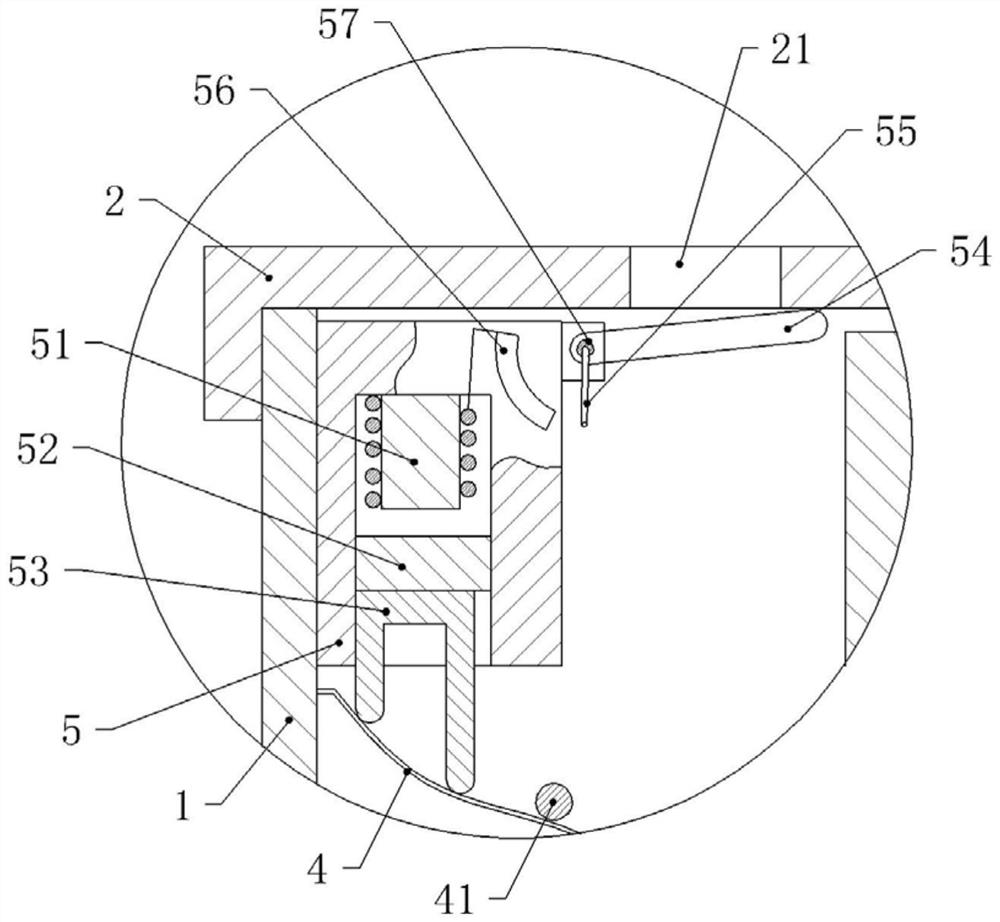

[0026] Embodiment 1, a kind of anti-loosening socket, such as figure 1 As shown, it includes a socket body 1, an upper cover 2 and a reed 4. The upper cover 2 is provided with a jack, and the reed 4 is provided with an arc-shaped raised portion that contacts the insertion piece 3. The raised portion is provided with two Two arc-shaped protrusions, when the insert 3 is inserted into the socket and contacts the reed 4, the two arc-shaped protrusions make the reed 4 and the insert 3 form a multi-point contact, which is beneficial to reduce the contact between the reed 4 and the insert. 3 friction and increased conductivity, a rectifier is provided in the socket body, and the rectifier is electrically connected to the socket power supply, and a fixing rod 41 is set on the upper and lower sides of the outer side of the arc-shaped protrusion of the reed 4, and the fixing rod 41 is connected to the socket body 1 Fixedly connected, the fixed rod 41 is contacted and connected with the ...

Embodiment 2

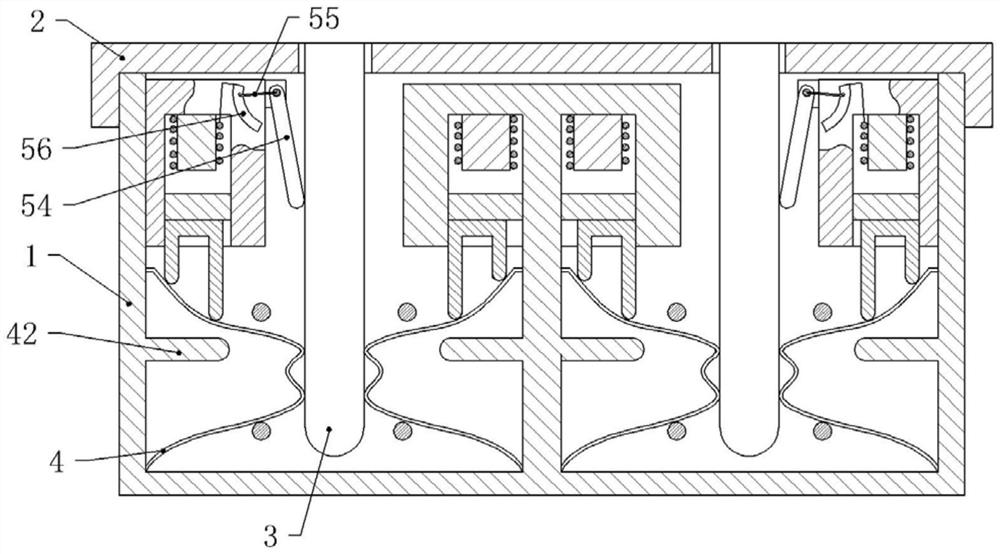

[0030] Embodiment 2: The difference from Embodiment 1 is that: the resistance plate 56 and the metal slide bar 55 are canceled, and a push switch 31 is provided on the bottom plate of the socket body corresponding to the jack 21, and the push switch 31 is connected in series to one of the rectifiers. between one output power line and one end of the electromagnet coil, and the other end of the electromagnet coil is electrically connected to another output power line of the rectifier.

[0031] The working process of the second embodiment is: when the insertion piece 3 is not inserted into the socket, the rotating plate 54 blocks the jack 21 under the elastic force of the torsion spring, and when the insertion piece 3 is inserted through the jack 21, the insertion piece 3 pushes the rotating plate 54 Rotating around the rotating shaft 57, when the insert piece 3 is inserted into the socket body and presses the push switch 31 on the bottom plate, the coil of the electromagnet 51 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com