Paint spraying and plastic spraying equipment painting mist circulating recycling system and full-automatic paint spraying and plastic spraying device

A technology of recycling and equipment, applied in the direction of spraying devices, spray booths, etc., can solve the problems of excessive paint waste and environmental pollution, and achieve the effect of realizing recycling, reducing waste, and meeting the needs of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

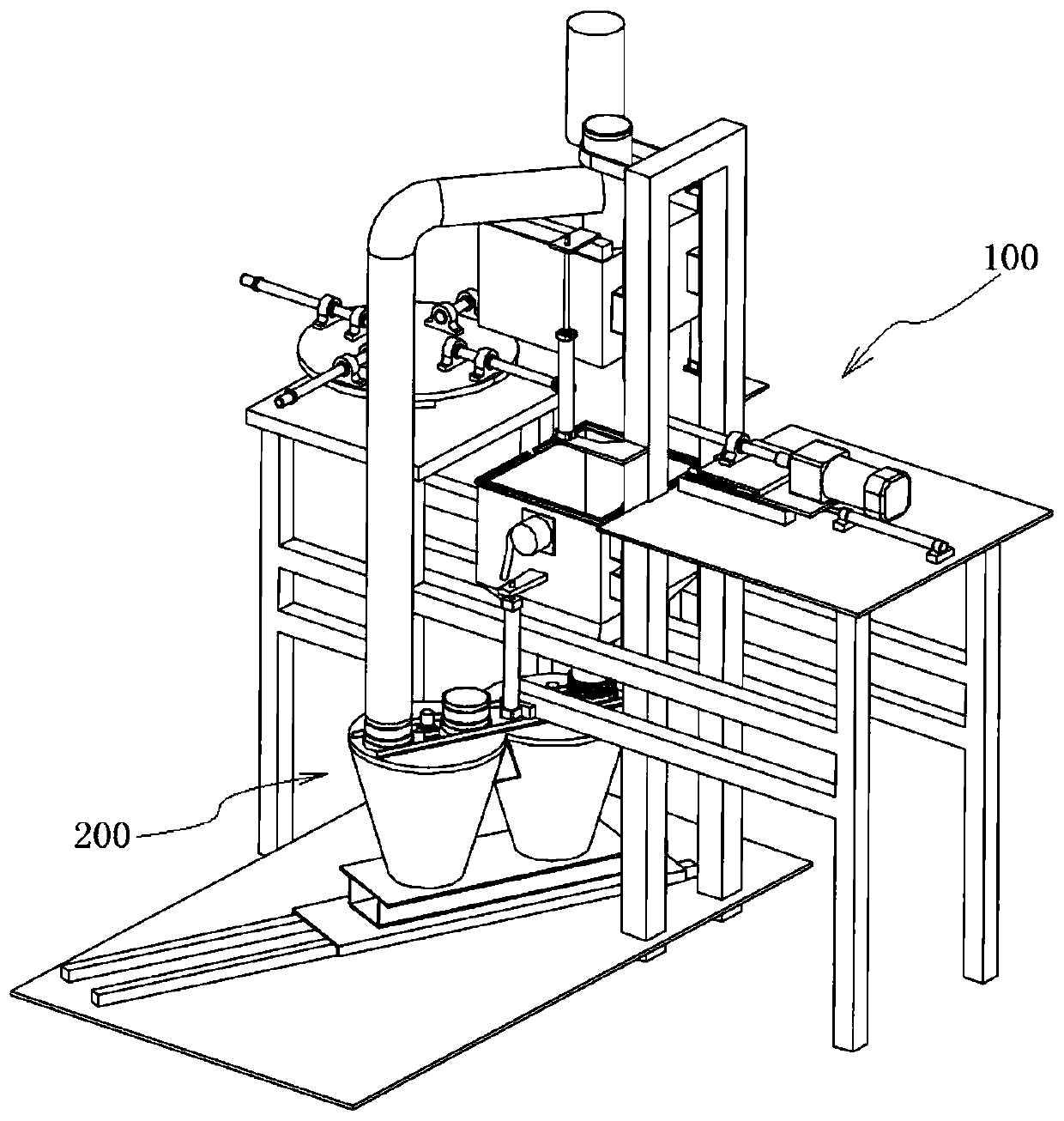

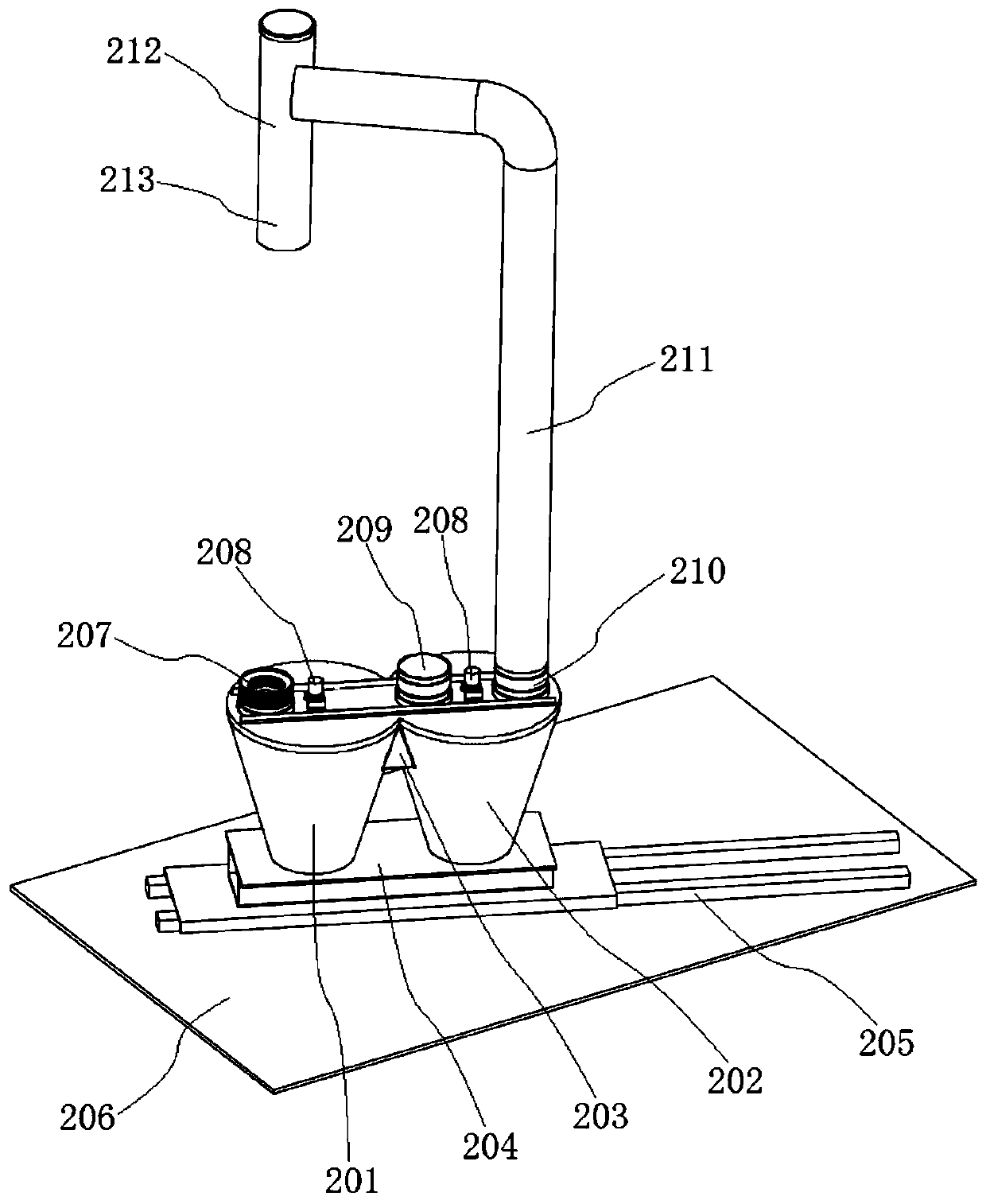

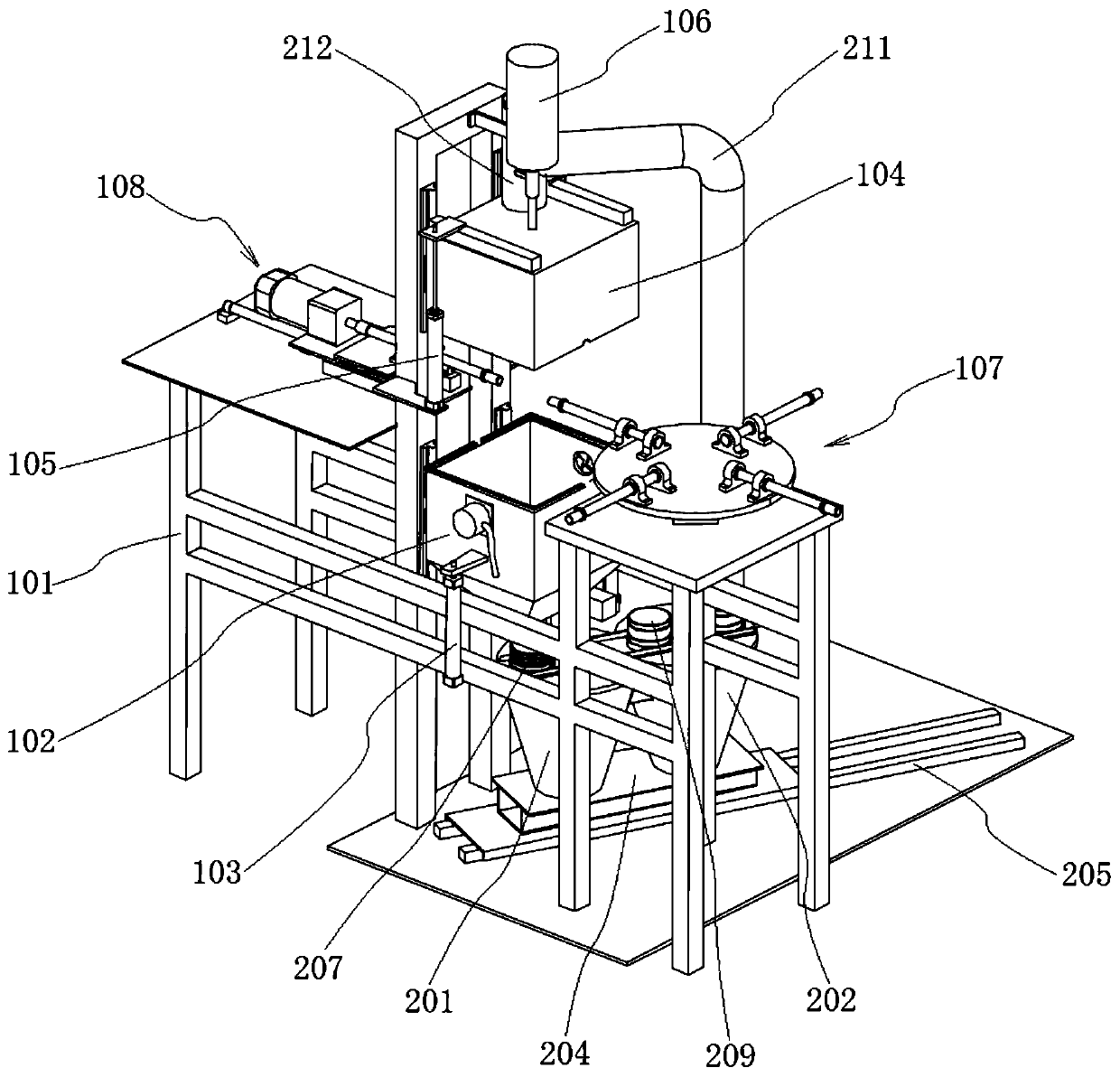

[0030] combine figure 1 , figure 2 and image 3As shown, a paint mist circulation recovery system for spray paint and plastic spraying equipment in this embodiment includes at least two recovery barrels and a circulation delivery pipe 211, and two adjacent recovery barrels are connected through a communication bridge 203, and each recovery Stirring mechanism 208 is arranged in the bucket, and stirring mechanism 208 comprises a motor and a stirring rod, and the motor is installed on the top of the recovery bucket, and the stirring rod is connected with the output shaft of the motor, and the motor drives the stirring rod to rotate to stir the collected paint. Contribute to the absorption of the paint droplets in the paint mist; among multiple recovery buckets, the top of the recovery bucket positioned at the front is provided with a connecting pipe 207 for being connected with the spray booth of the spray paint and plastic spraying equipment 100, and the recovery bucket positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com