Pressurized water reactor pressure stabilizer spray head connecting structure with labyrinth seal structure

A technology of labyrinth sealing and connection structure, which is applied in the direction of injection devices, etc., can solve the problems of local stress concentration and affecting the performance of the material performance of the nozzle nozzle of the spray head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

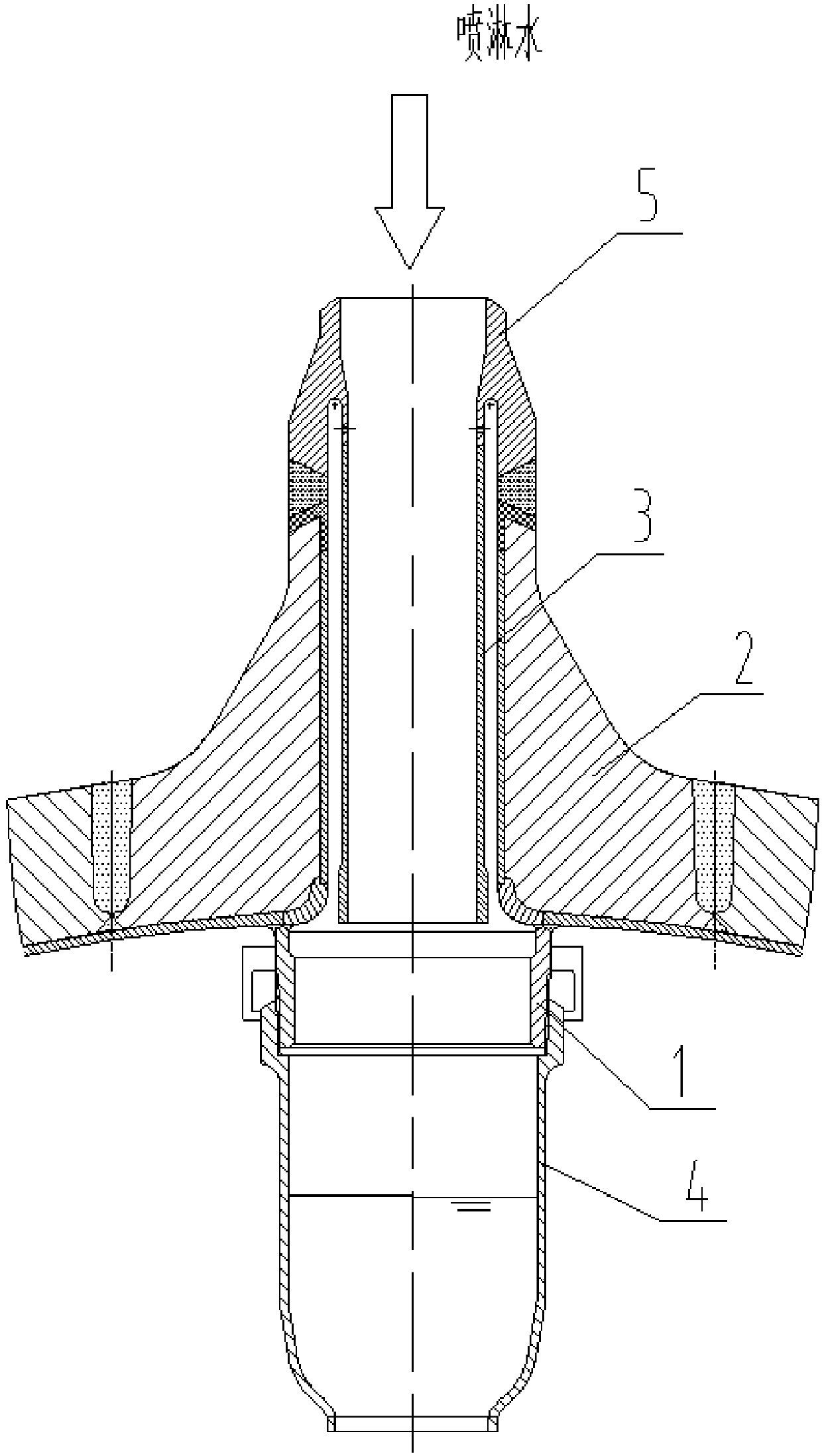

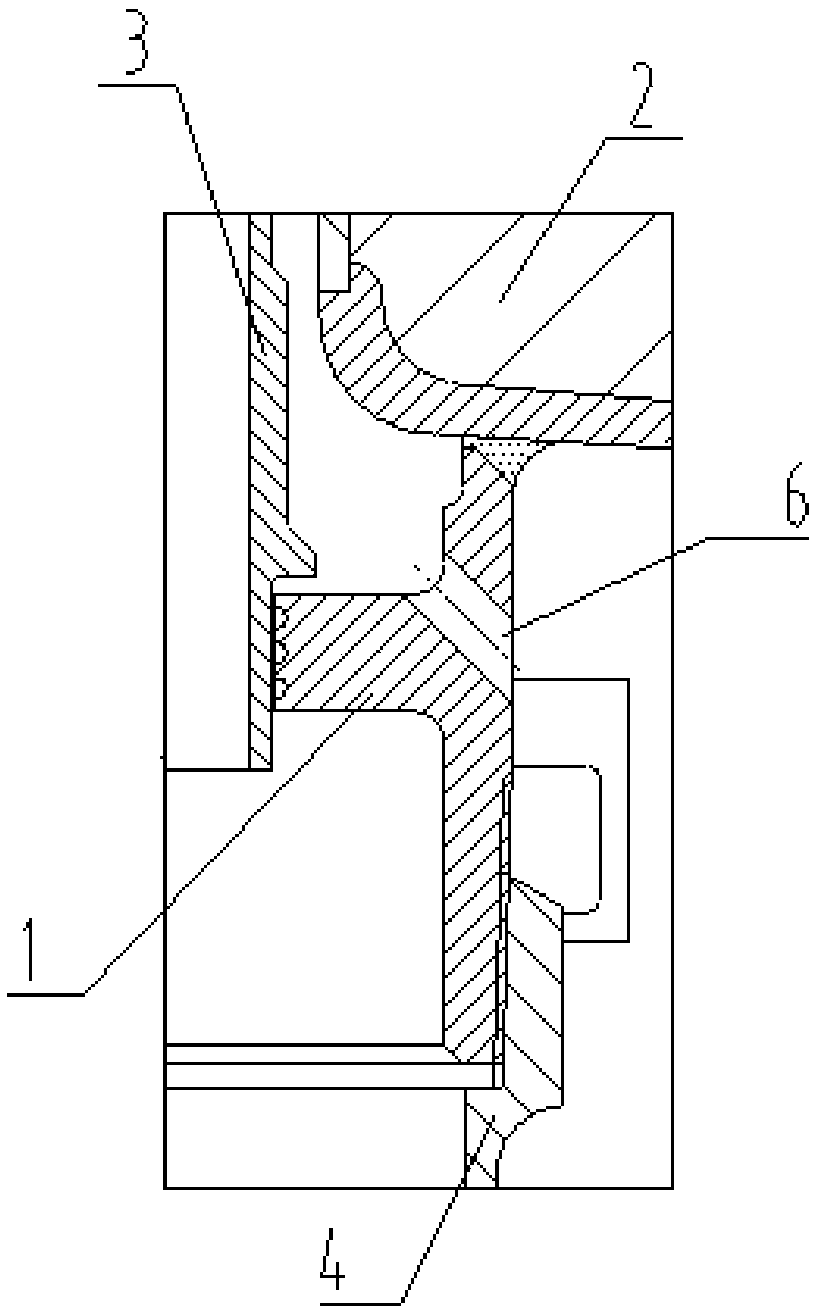

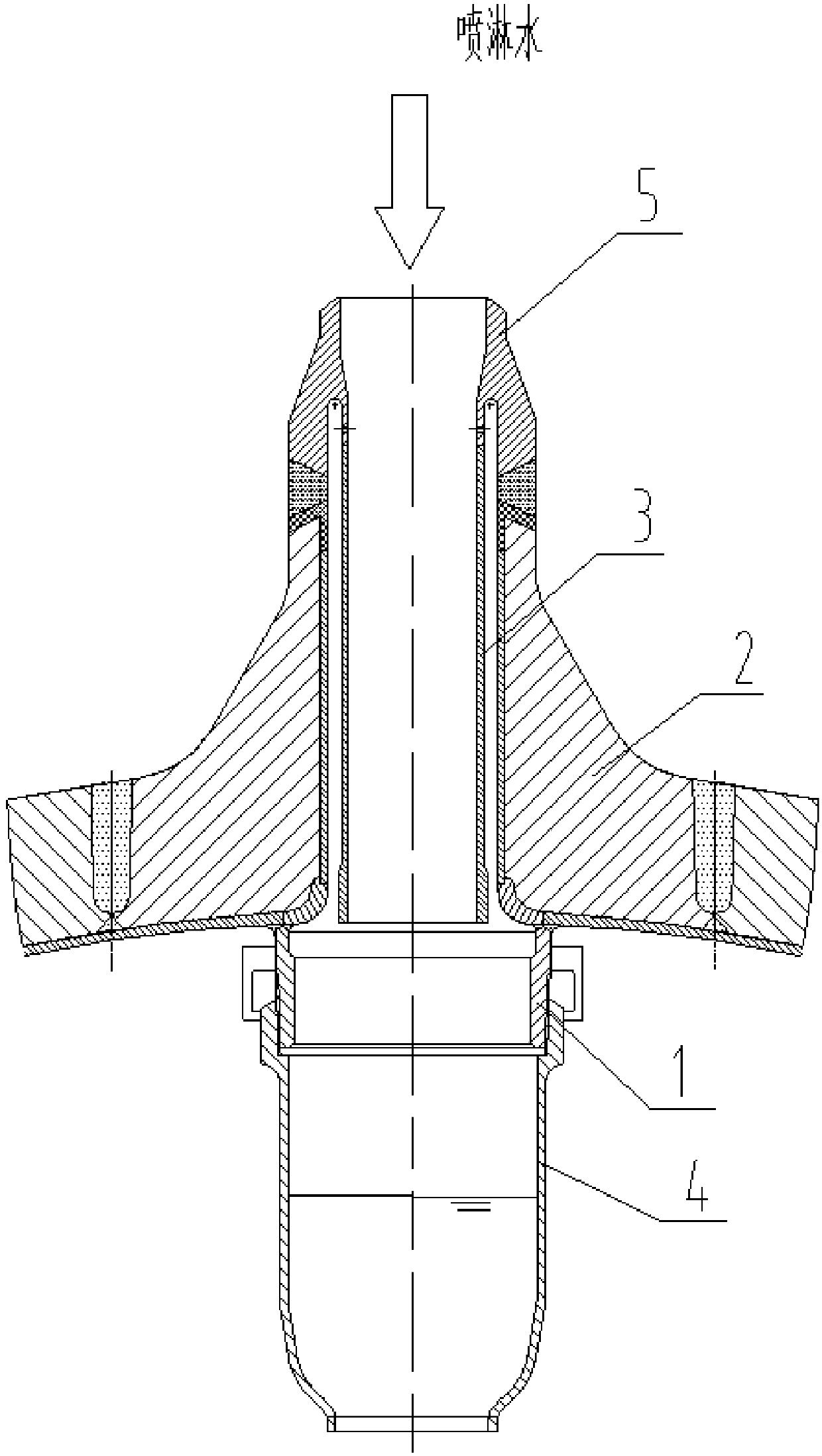

[0022] as attached figure 2 As shown, the spray water inlet flow rate in the spray head assembly is lower than or equal to the spray flow rate, the spray water enters the spray head assembly, and under the spray pressure, the spray water enters the internal space of the regulator through the spray head assembly, The spray water level in the spray head assembly is always lower than the spray head connecting pipe.

Embodiment 2

[0024] as attached figure 2 As shown, the spray water inlet flow rate in the spray head assembly is higher than the spray flow rate, the spray water enters the spray head assembly, and under the action of the spray pressure, the spray water sprays into the internal space of the regulator. The level of the inner spray water keeps rising, and the spray water flows through the labyrinth sealing structure and then fills into the space formed by the upper part of the spray head connecting pipe and the spray head heat-shock protection sleeve, and quickly exits the spray head connecting pipe through the discharge hole.

Embodiment 3

[0026] as attached figure 2 As shown, the welding seam between the spray head thermal shock protection sleeve and the safety end of the spray head nozzle is broken, the spray head heat shock protection sleeve falls to the boss in the middle of the spray head connection pipe, and the boss in the middle of the spray head connection pipe Provides support for the thermal shock sleeve, which retains some thermal shock protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com