Automatic cutting machine

A cutting machine and cutting mechanism technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of shortened life, reduced accuracy, large front and rear pitching torque, etc. The effect of inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

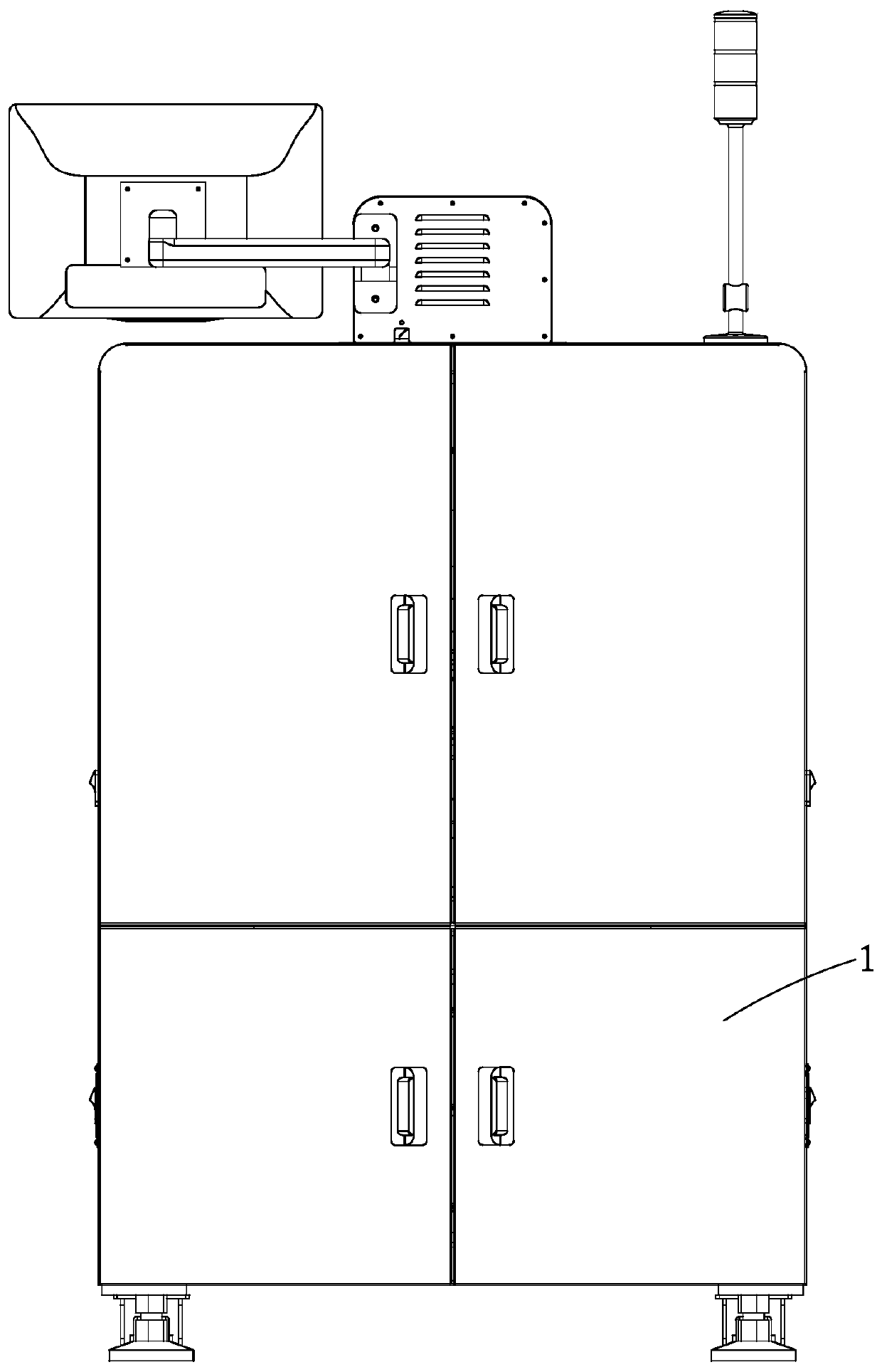

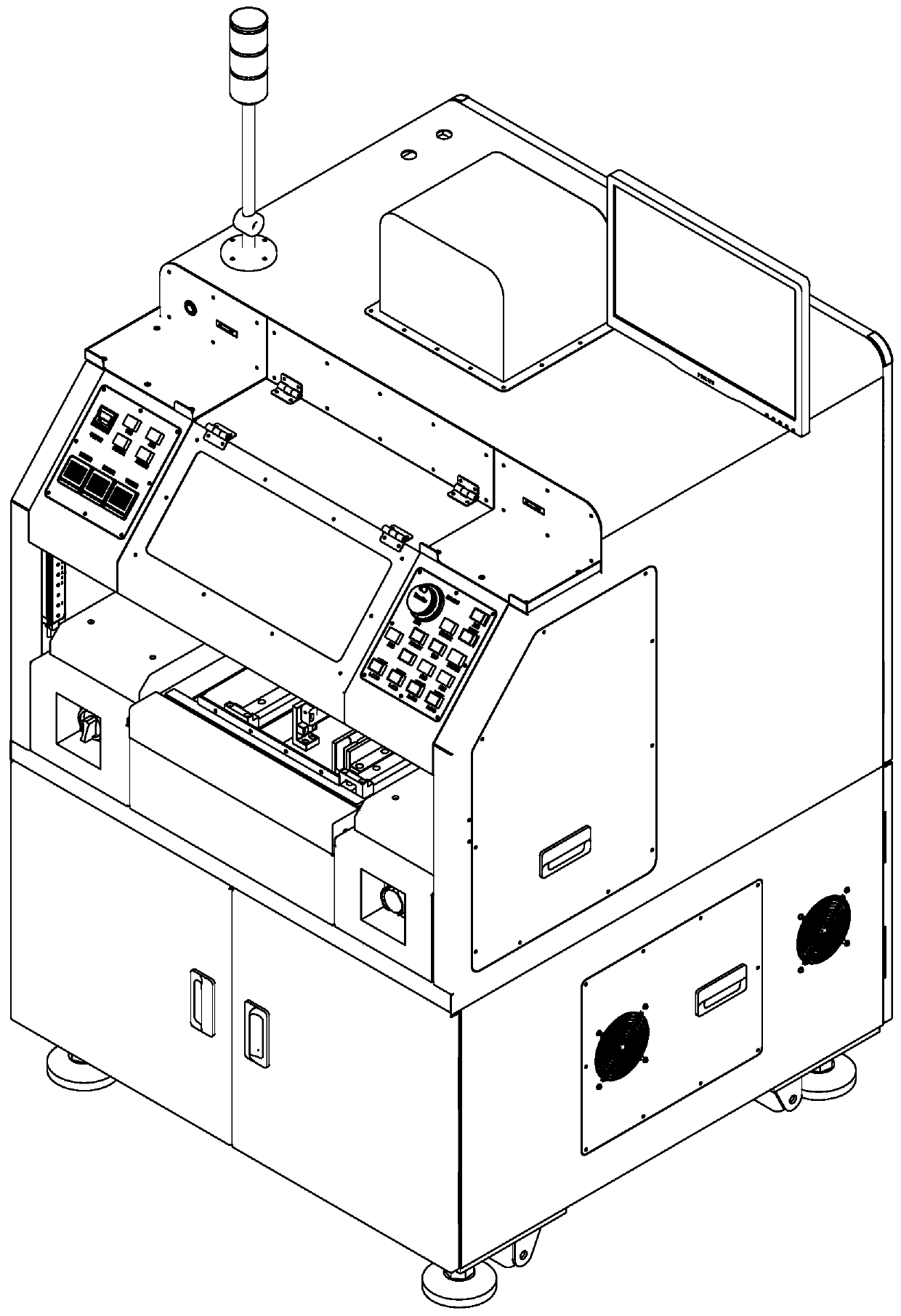

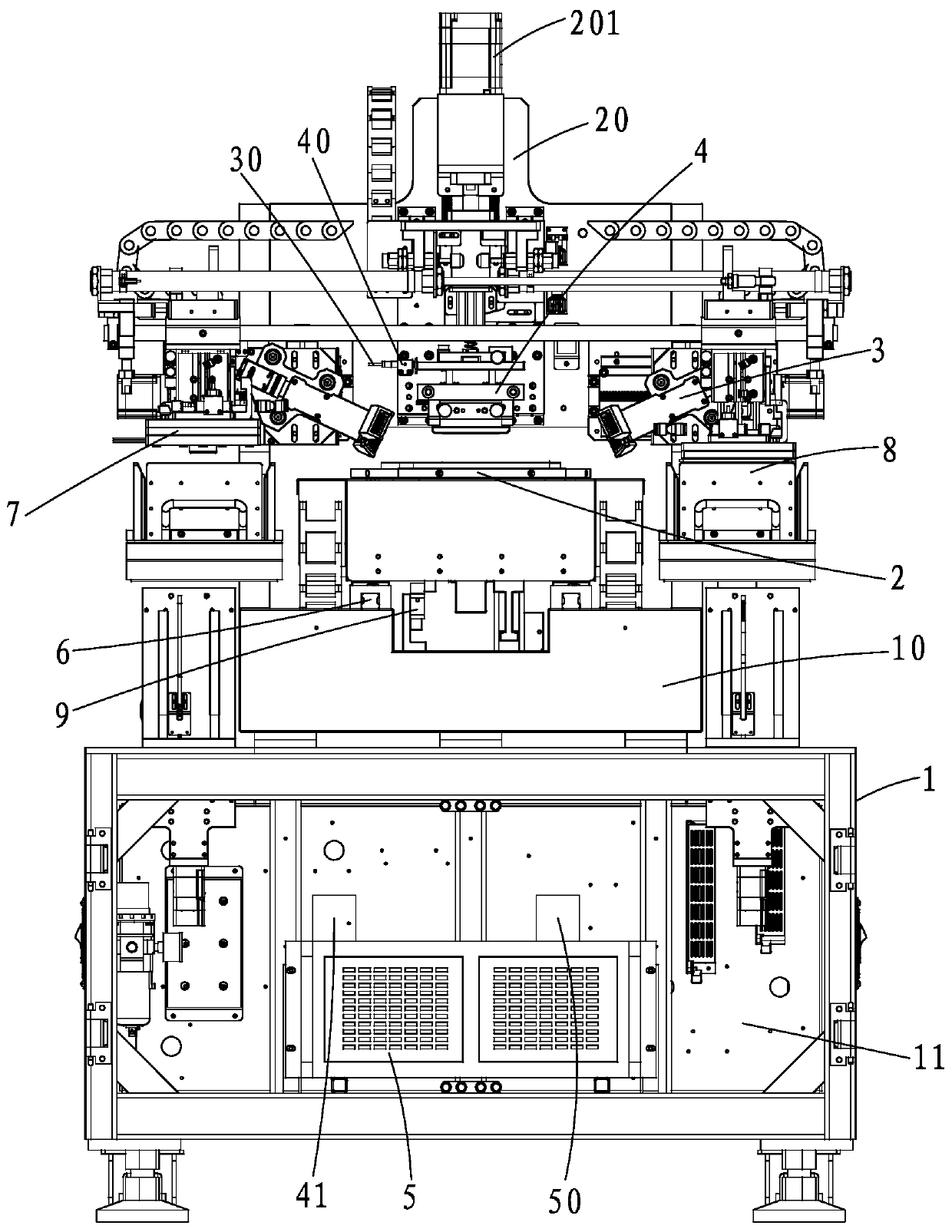

[0060] see Figures 1 to 21 As shown, the present invention provides an automatic cutting machine, including a body structure 1, a carrier 2, a detection and positioning mechanism 3, a cutting mechanism 4, a control system 5 and two guide rails 6, and a vacuum channel is provided inside the carrier 2, and the The left and right sides of the carrier 2 are also respectively provided with a vacuum suction cup, a transmission motor, a feeding mechanism 7 and a receiving mechanism 8; There is a DD direct drive servo rotation mechanism (not shown) that can allow the carrier 2 to rotate a certain angle relative to the carrier plate 21, and a direct drive mechanism 9 that can make the carrier plate 21 move linearly forward and backward is arranged below the carrier plate 21; the detection and positioning Mechanism 3 includes two groups of CCD detectors 31 arranged left and right, each group of said CCD detectors 31 includes a CCD lens 311, a motor 312, and a camera fine-tuning device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com