A universal motion platform for highly adaptable robots for complex nuclear environments

A complex environment and motion platform technology, applied in the field of robotics, can solve the problems of no landing buffer considerations, etc., to achieve the effect of convenient turning in place, large rotation range and robot height adjustment range, and reduced envelope size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

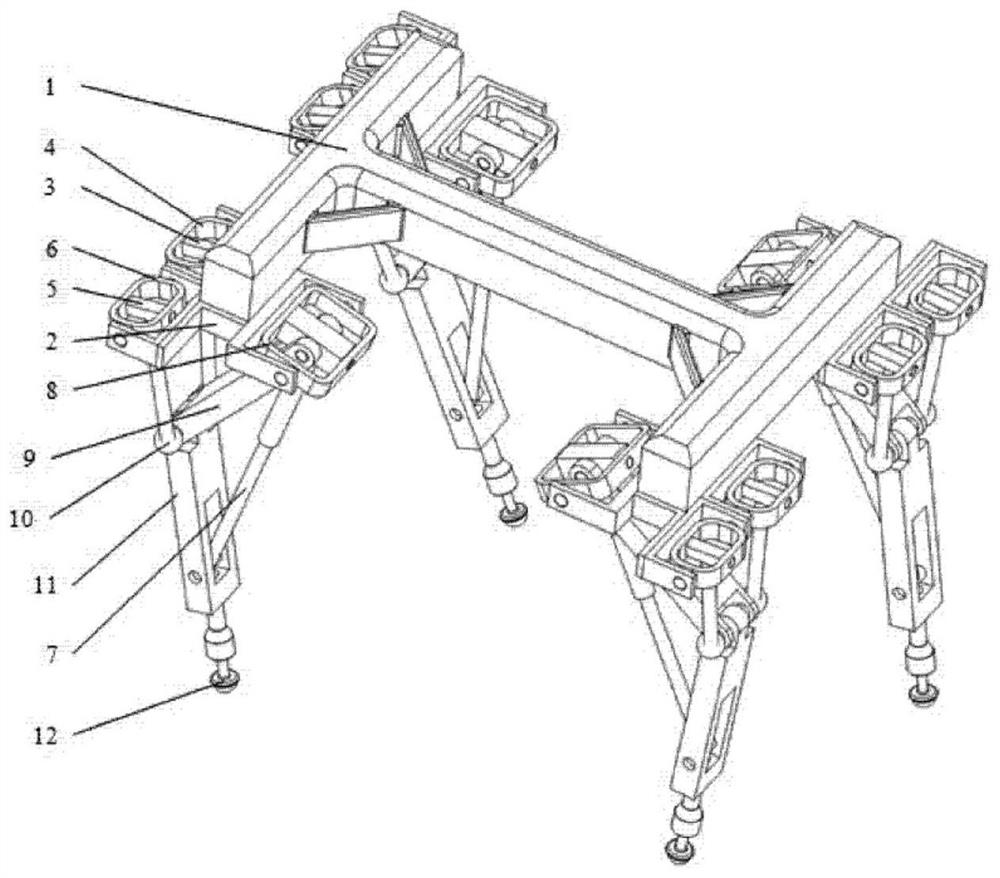

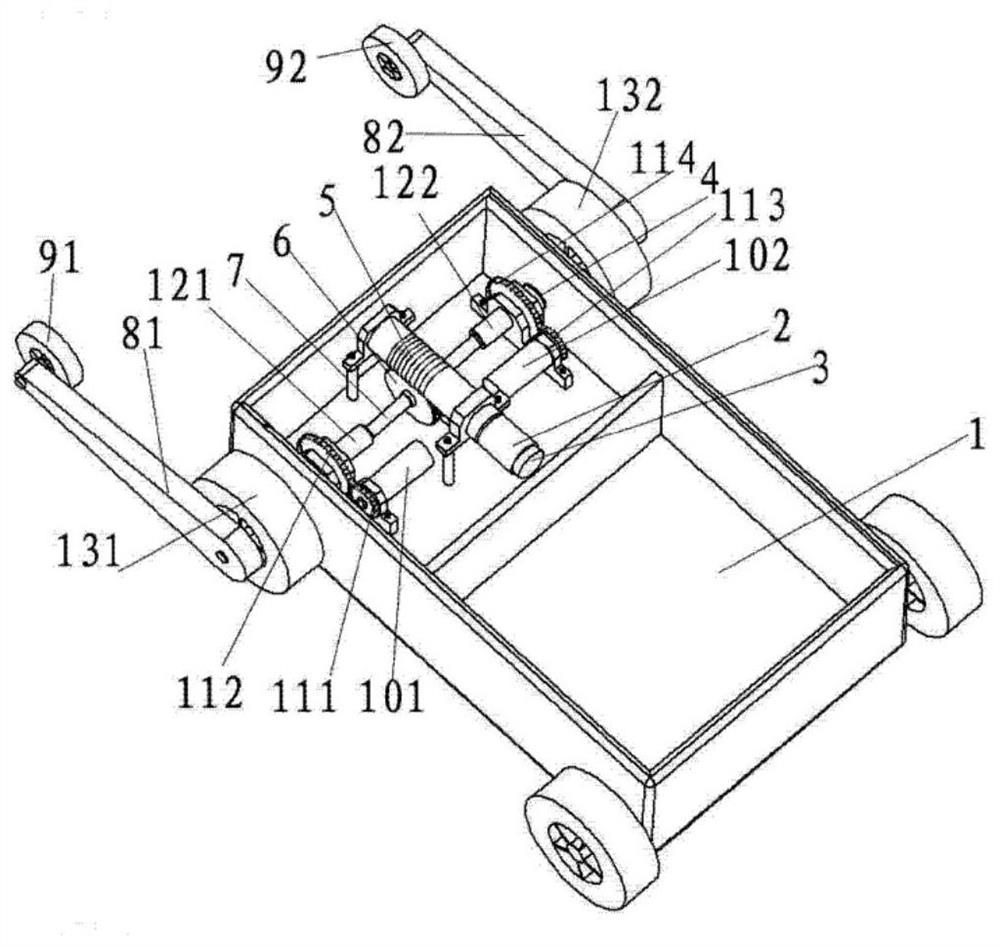

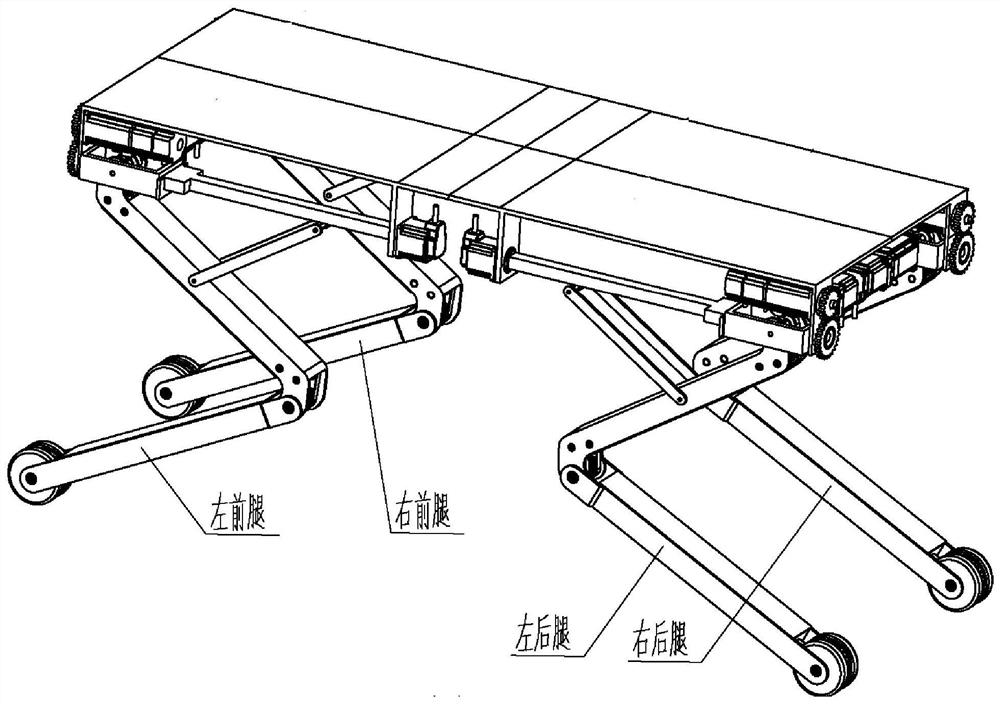

[0050] As shown in the figure, the outer layer of the robot is designed with a shielding protective shell, and its internal structure mainly includes four multi-degree-of-freedom robot leg systems, and each robot leg system has four degrees of freedom. With the robot body as the base, the 4 degrees of freedom are the hip joint "abduction / adduction" and "extension / bend", the knee joint "extension / bend", and the roller at the end of the leg kinematics;

[0051] The four legs of the robot adopt a unified modular design and are distributed symmetrically. Taking the left hind leg as an example, the internal structure is described.

[0052] Two mounting plates protrude from the lower side of the mounting base plate of the left rear leg, which are respectively connected to the ball screw mounting rod seat and the hip joint "abduction / adduction" motion base through a pair of bearings;

[0053] The driving motor of the hip joint "abduction / adduction" and its integrated reduction box ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com