Cable winding device

A cable winding and photoresistor technology is applied in the cable field, which can solve the problems of slow winding speed, time-consuming and laborious winding, and increase in the cost of cable winding, and achieves the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

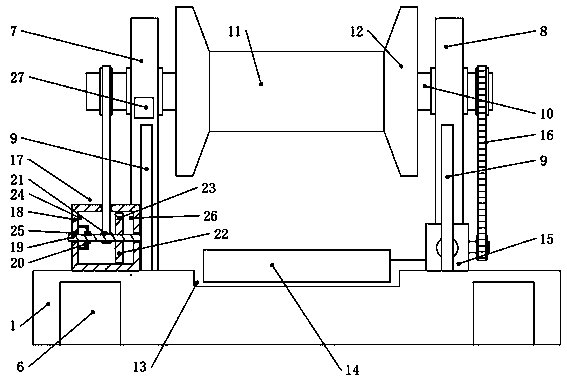

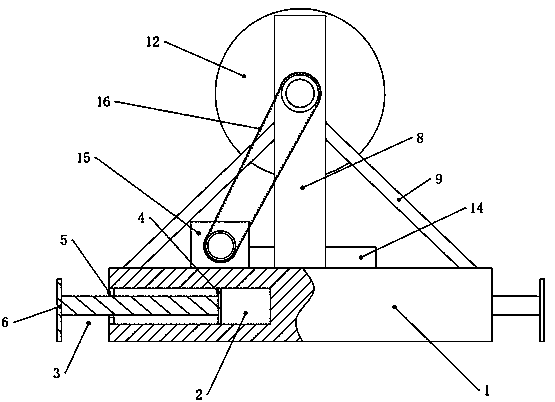

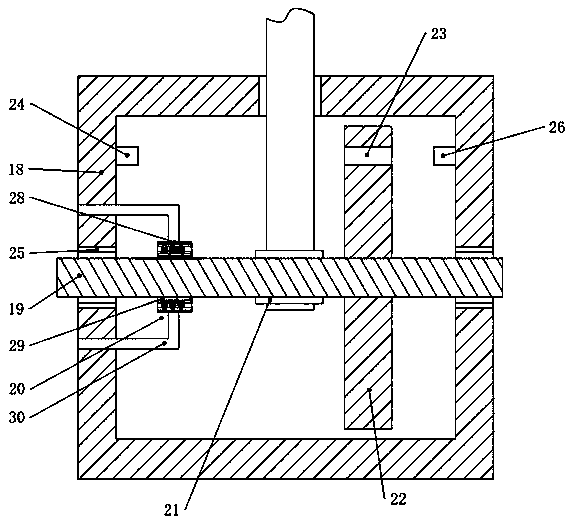

[0024] refer to Figure 1-Figure 8 As shown, the cable winding device includes a base plate 1, a corresponding left bracket 7 and a right bracket 8 are arranged on the length direction of the upper part of the base plate 1, and the left bracket 7 and the right bracket 8 are pierced with rollers arranged along the length direction of the base plate 1. The shaft 10, the bottom plate 1 between the left bracket 7 and the right bracket 8 is provided with a groove 13, and an electric storage box 14 is installed in the groove 13, and an electric box 15 is installed on the bottom plate 1 on one side of the right bracket 8, A speedometer 17 is installed on the base plate 1 on one side of the left support 7 .

[0025] refer to figure 1 and figure 2 As shown, the bottom plate 1 is a rectangular bottom plate, and two embedded holes 2 extending into the bottom plate 1 are provided on both side walls of the bottom plate 1 in the width direction, and the embedded holes 2 are symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com