Graphene water-based zinc silicate coating, its application and anti-corrosion coating

An anti-corrosion coating, alkene water-based technology, used in alkali metal silicate coatings, anti-corrosion coatings, coatings, etc., can solve problems such as poor anti-corrosion performance, and achieve improved adhesion, excellent cathodic corrosion protection performance, and superior cathodic corrosion. The effect of protective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

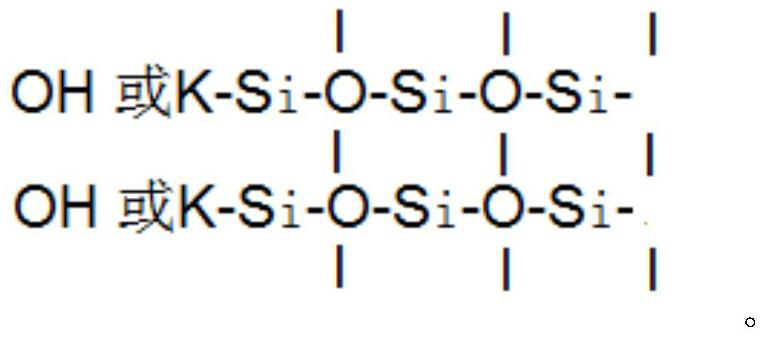

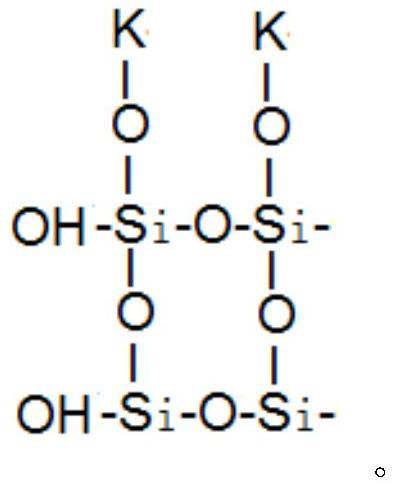

Method used

Image

Examples

Embodiment 1 to 5

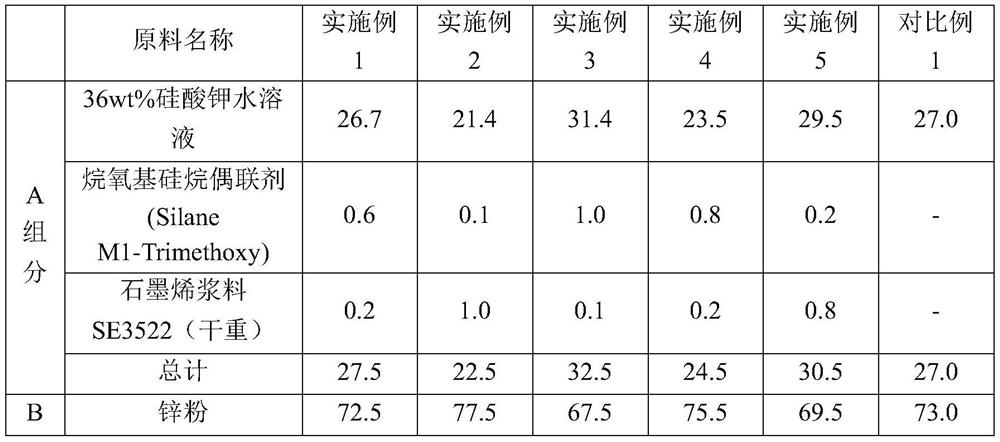

[0071] The composition of the graphene water-based zinc silicate paint in Examples 1 to 5 of the present invention is shown in Table 1 (represented in parts by weight), and the production technique is as follows:

[0072] Component A: Mix potassium silicate solution (the molar ratio of silica to alkali metal oxide is 5.5), silane coupling agent and graphene slurry uniformly.

[0073] Component B: Zinc powder (particle size 5-9 microns).

[0074] Before use, according to the weight ratio shown in Table 1, the A component and the B component are mixed to prepare the graphene water-based zinc silicate coating of the present invention.

Embodiment 6

[0093] The difference from Example 1 is that the molar ratio of silica to alkali metal oxide is 5.0:1.

Embodiment 7

[0095] The difference from Example 1 is that the particle size of the zinc powder is relatively uniform, and the particle size is 8 μm.

[0096] Table 2

[0097]

[0098] From the above description, it can be seen that the above-mentioned embodiments of the present invention achieve the following technical effects:

[0099]The combination of potassium silicate solution and zinc powder can quickly self-cure to form a hard thick film coating, providing superior cathodic corrosion protection, hardness, wear resistance and heat resistance, self-healing and continuous protection when the coating is damaged . Adding a silane coupling agent can make the dehydration more uniform, thereby improving the adhesion of the coating to the steel. The addition of graphene can increase the overall strength of the coating and further improve the adhesion of the inorganic coating on the steel surface. The above factors make the graphene water-based zinc silicate coating provided by the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com