On-line detection device and method for external dimension of fuel pellet

A technology for fuel pellets and detection devices, which is applied to measurement devices, uses optical devices, analyzes materials, etc., can solve the problems of low detection efficiency, inability to perform manual intervention, inability to detect the length of pellets, central aperture and chamfer size, etc. , to achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides an online detection device for the appearance size of fuel pellets, which is suitable for online detection of the appearance size of various types of fuel pellets, especially for online detection of the appearance size of MOX nuclear fuel pellets.

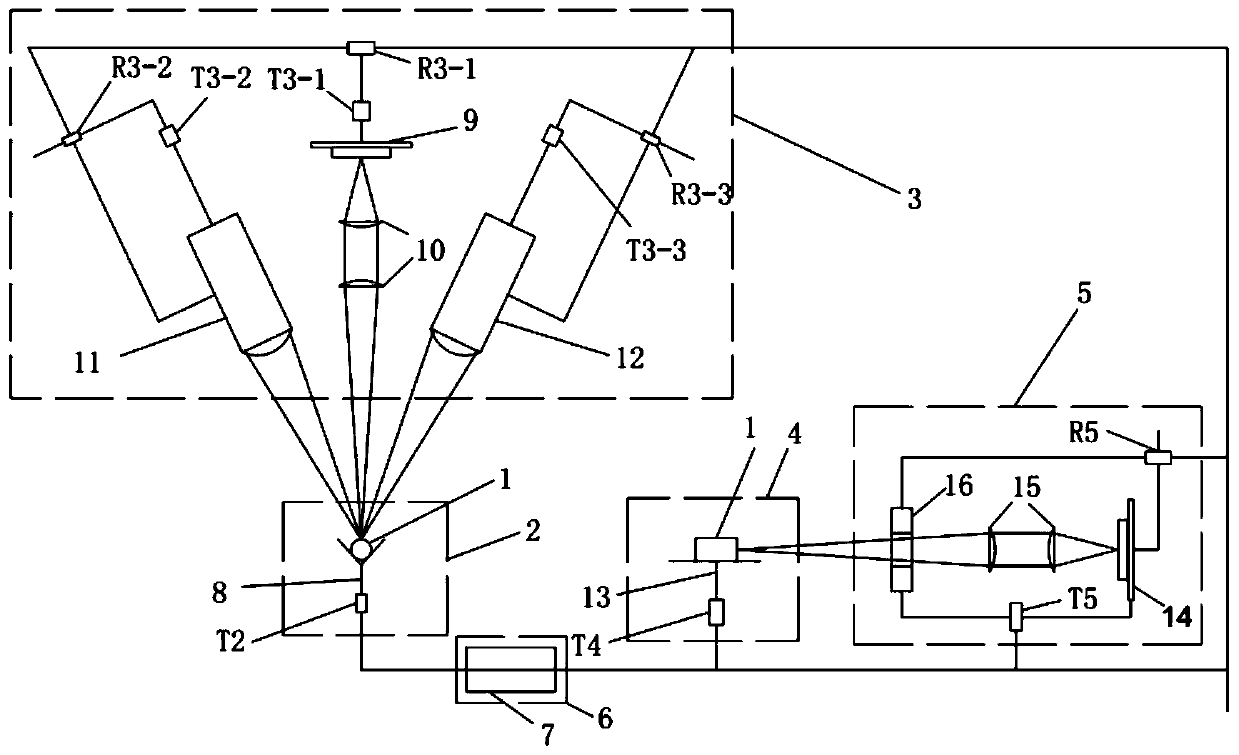

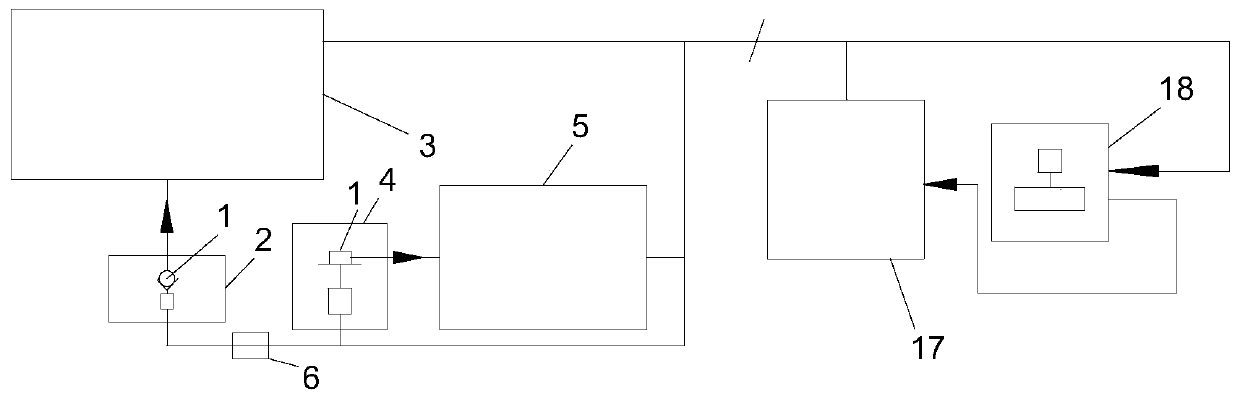

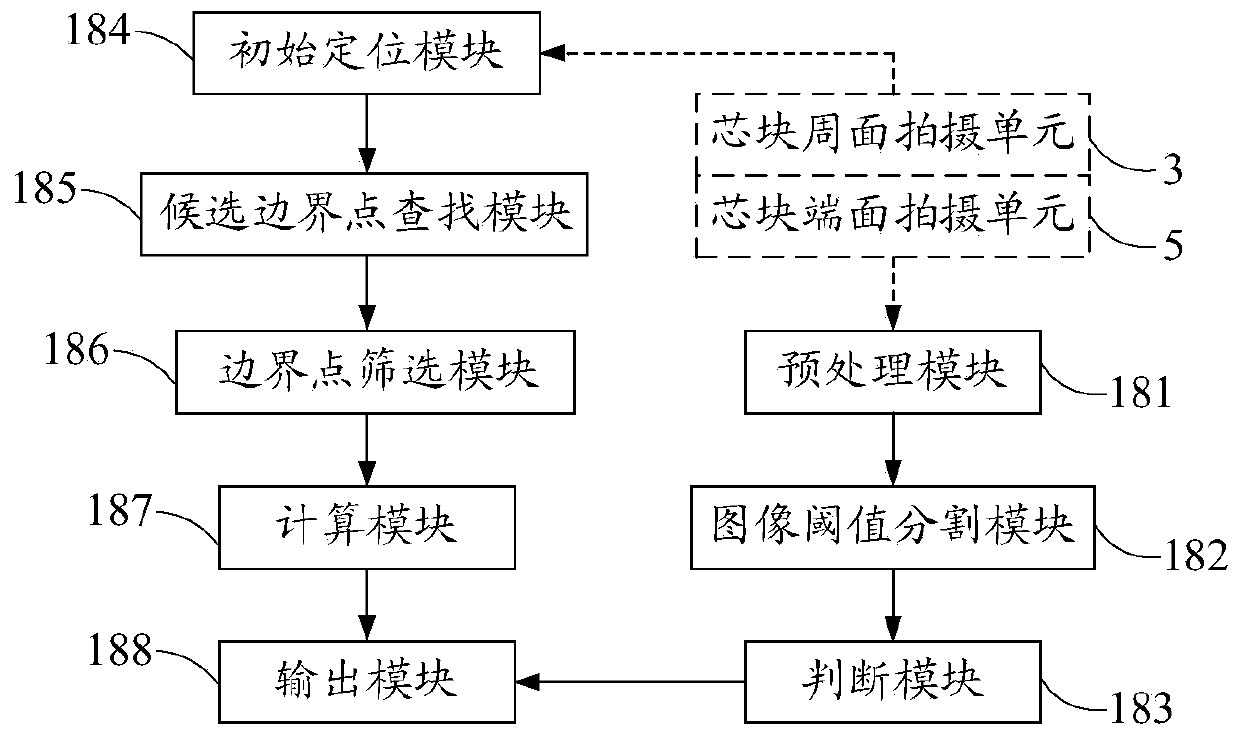

[0065] Such as figure 1 and figure 2 As shown, the online detection device includes: a pellet rotation unit 2 , a pellet peripheral surface photographing unit 3 , a pellet transfer unit 6 , a pellet end surface photographing unit 5 , an image processing unit 18 and a control unit 17 .

[0066] The pellet rotating unit 2 is used to drive the fuel pellet 1 at the first preset position to rotate around its axis at a constant speed, so as to ensure complete image acquisition of the peripheral surface of the fuel pellet. The pellet peripheral surface photographing unit 3 is used to continuously photograph the peripheral surface of the fuel pellet 1 during the rotation of the fuel pellet 1 to obtain a co...

Embodiment 2

[0116] This embodiment provides an online detection method for the appearance size of fuel pellets, which is suitable for online detection of the appearance size of various types of fuel pellets, and is especially suitable for online detection of the appearance size of MOX nuclear fuel pellets.

[0117] Such as Figure 4 As shown, as a specific implementation manner of this embodiment, the online detection method includes the following steps S101 to S105.

[0118] S101. Driving the fuel pellet at the first preset position to rotate at a constant speed around its axis;

[0119] S102. Continuously photographing the peripheral surface of the fuel pellet during the rotation of the fuel pellet to obtain a complete image of the peripheral surface of the fuel pellet;

[0120] S103. Automatically transfer the fuel pellets from the first preset position to the second preset position;

[0121] S104. Shooting the end face of the fuel pellet at the second preset position to obtain a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com