Device for controlling temperature of power batteries by using battery magic square system

A power battery and Rubik's cube technology is applied in the field of devices for temperature control of power batteries by using a battery cube system, which can solve the problems of complex process, complicated structure, and inability to guarantee temperature uniformity, and achieve accurate temperature control and high heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

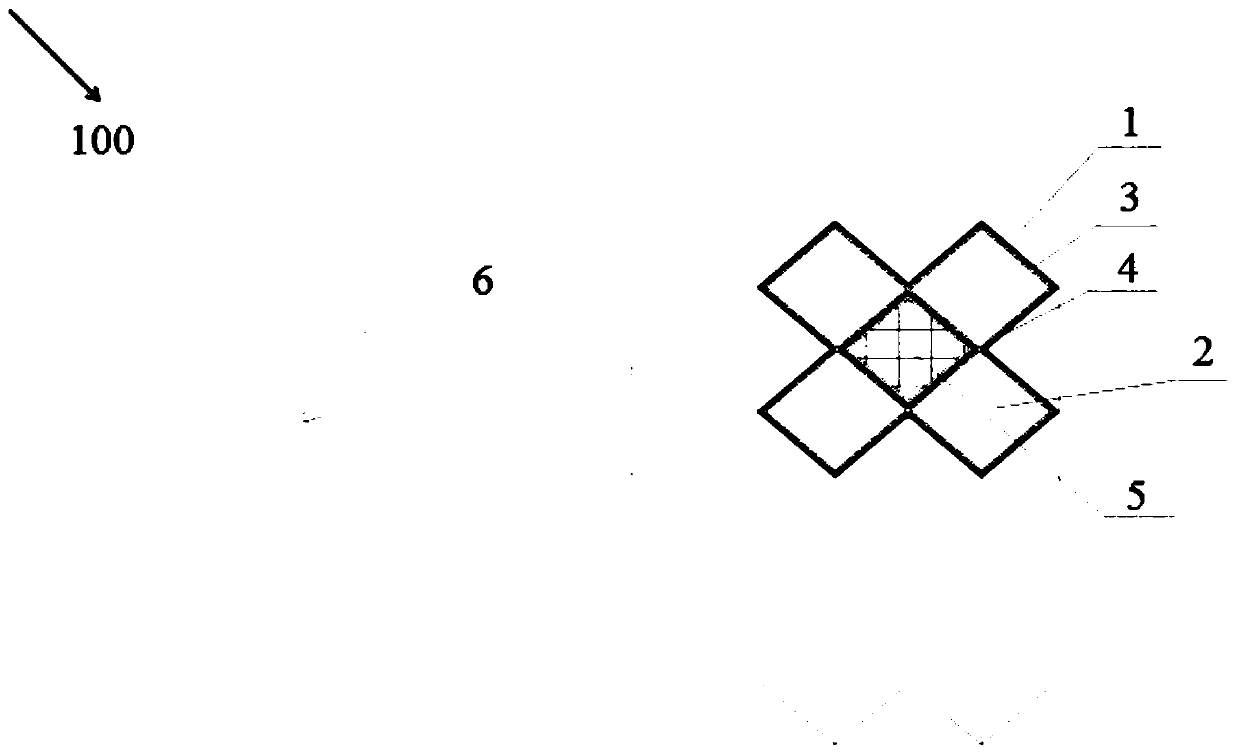

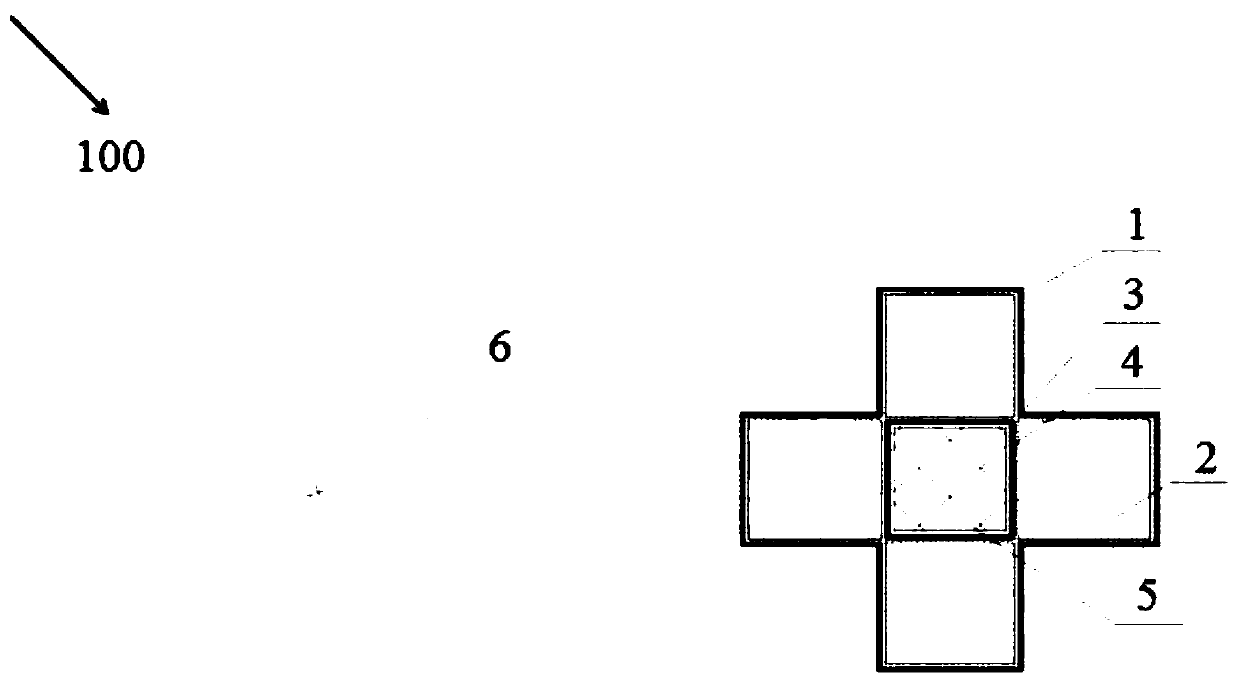

[0018] figure 1 It is a three-dimensional schematic diagram of a device for controlling the temperature of a power battery using a battery cube system in an embodiment of the present invention, figure 2 It is a top view of a device for controlling the temperature of a power battery using a battery cube system in an embodiment of the present invention.

[0019] Such as figure 1 with figure 2 As shown, the device 100 for controlling the temperature of a power battery using a battery cube system in this embodiment is used to control the temperature of a power battery core 2, which is used to provide energy, and includes: a battery cube system 1, Constant temperature micro-channel heat pipe heat exchanger group 3, temperature monitoring and control unit 5 and cooling equipment 6.

[0020] The battery cube system 1 covers the surface of multiple power battery cores 2, and the battery cube system 1 and each power battery core 2 are fixed by a thermally conductive fixing member 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com