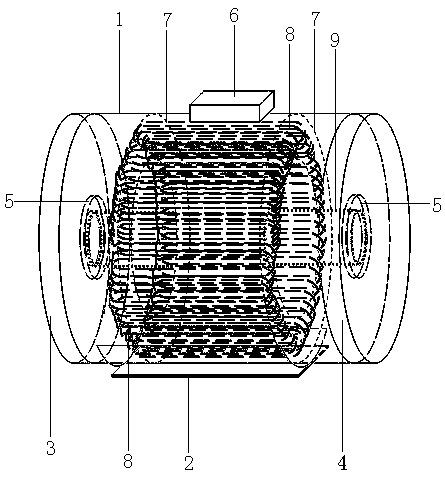

Operation method of fully-enclosed eccentric rotor vibration motor

A technology of vibrating motor and eccentric rotor, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of increasing the self-weight of the motor, being unable to bear the weight and volume of the motor, increasing the volume of the motor, etc., and achieving the effect of increasing the vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

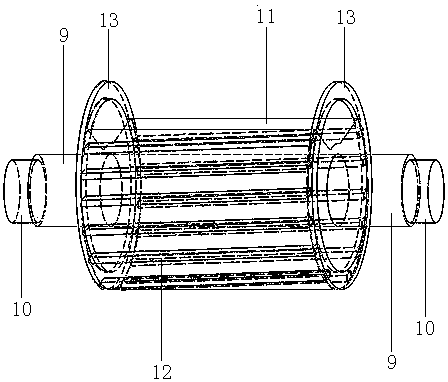

[0013] According to the above-mentioned fully enclosed eccentric rotor vibration motor in use, the worker first places the motor on the installation part of the supporting equipment, uses bolts to connect the machine feet of the motor to the equipment, opens the waterproof junction box, and connects the supporting power cord on the equipment to the equipment. Connect the terminals in the junction box and cover the waterproof junction box. When the equipment needs to vibrate, the equipment supplies current to the terminals of the vibration motor, and the terminals then supply the current to the coil windings. After the coil windings are energized, they are on the stator core. A magnetic field is generated instantaneously, and the magnetic field simultaneously generates a nest magnet on the rotor core. Since the guide bars and short-circuit rings are distributed on the rotor core to separate the nest magnetism into multiple magnetic fields, the rotor magnetic field and the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com