Laser cladding and ultrasonic vibration combined auxiliary rivet-free turning and riveting connecting device and connecting method

A technology of laser cladding and ultrasonic vibration, which is applied in the coating process and coating of metal materials, can solve problems affecting joint performance, electrochemical corrosion, metal fatigue, etc., to eliminate residual stress, improve surface strength, and reduce quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

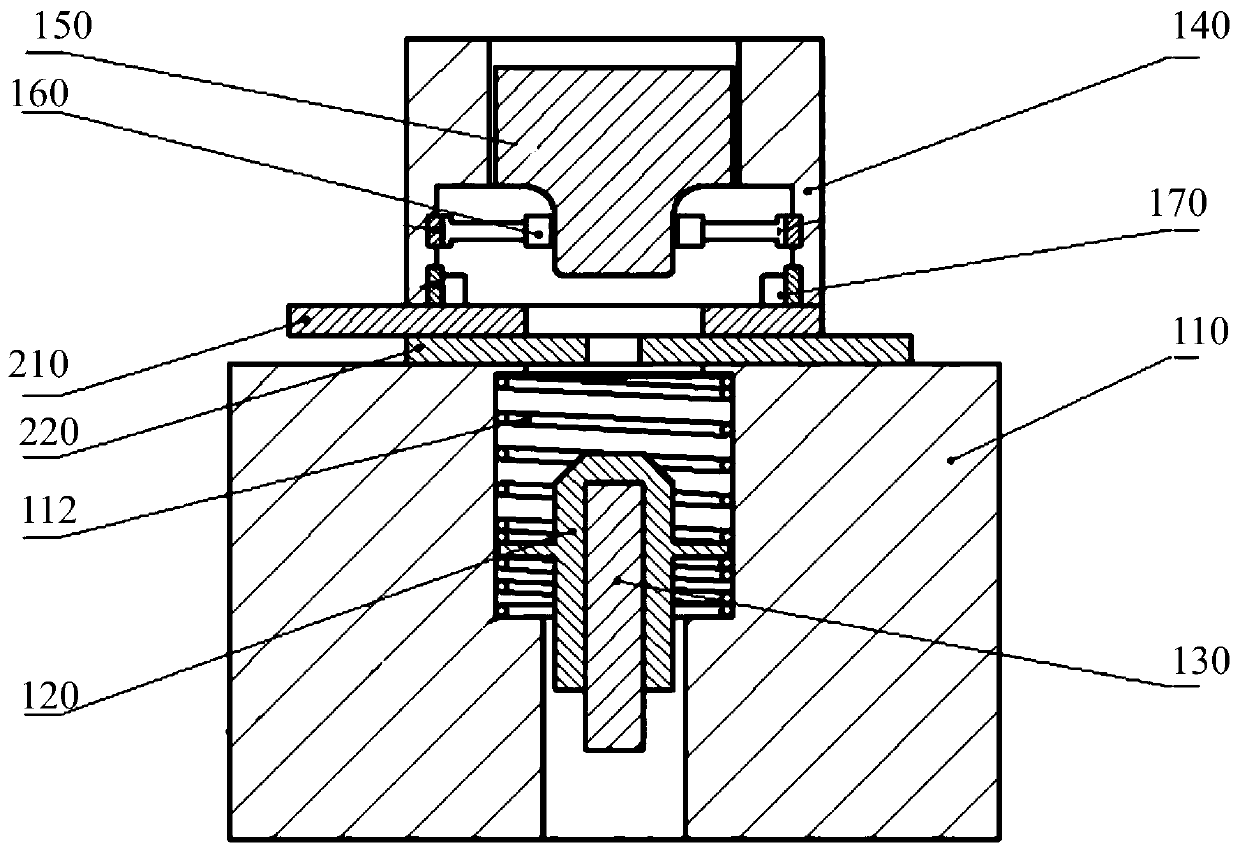

[0073] Such as figure 1 As shown, the laser cladding and ultrasonic vibration combined auxiliary rivetless turning riveting connection device provided by the present invention includes: base 110, downturning riveting punch 120, ultrasonic vibration device 130, blank holder 140, upturning riveting punch 150 , the first laser cladding device 160 and the second laser cladding device 170 .

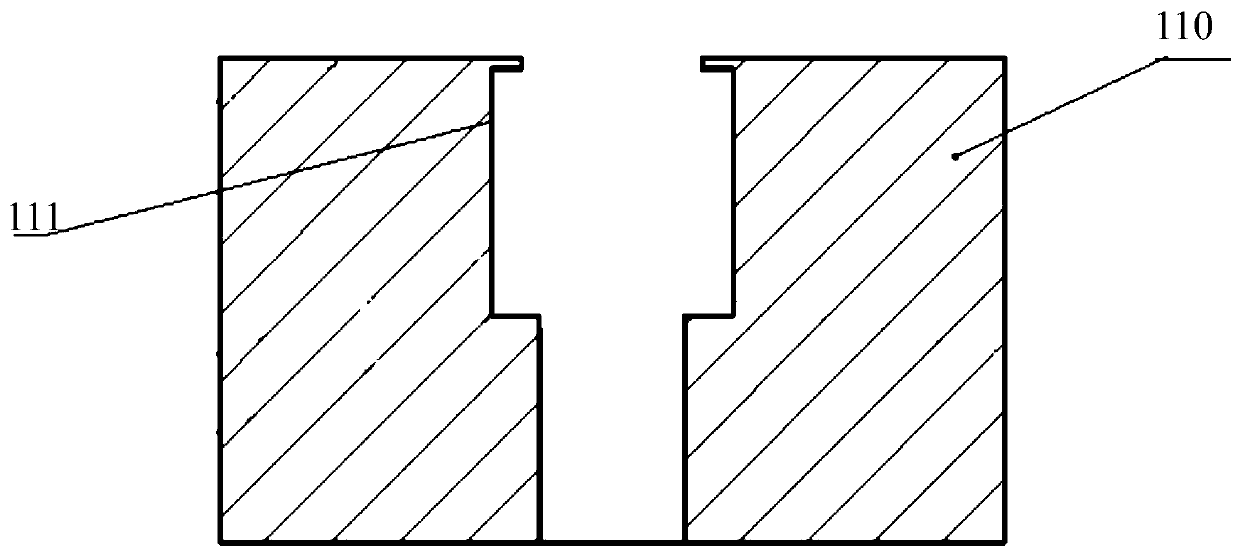

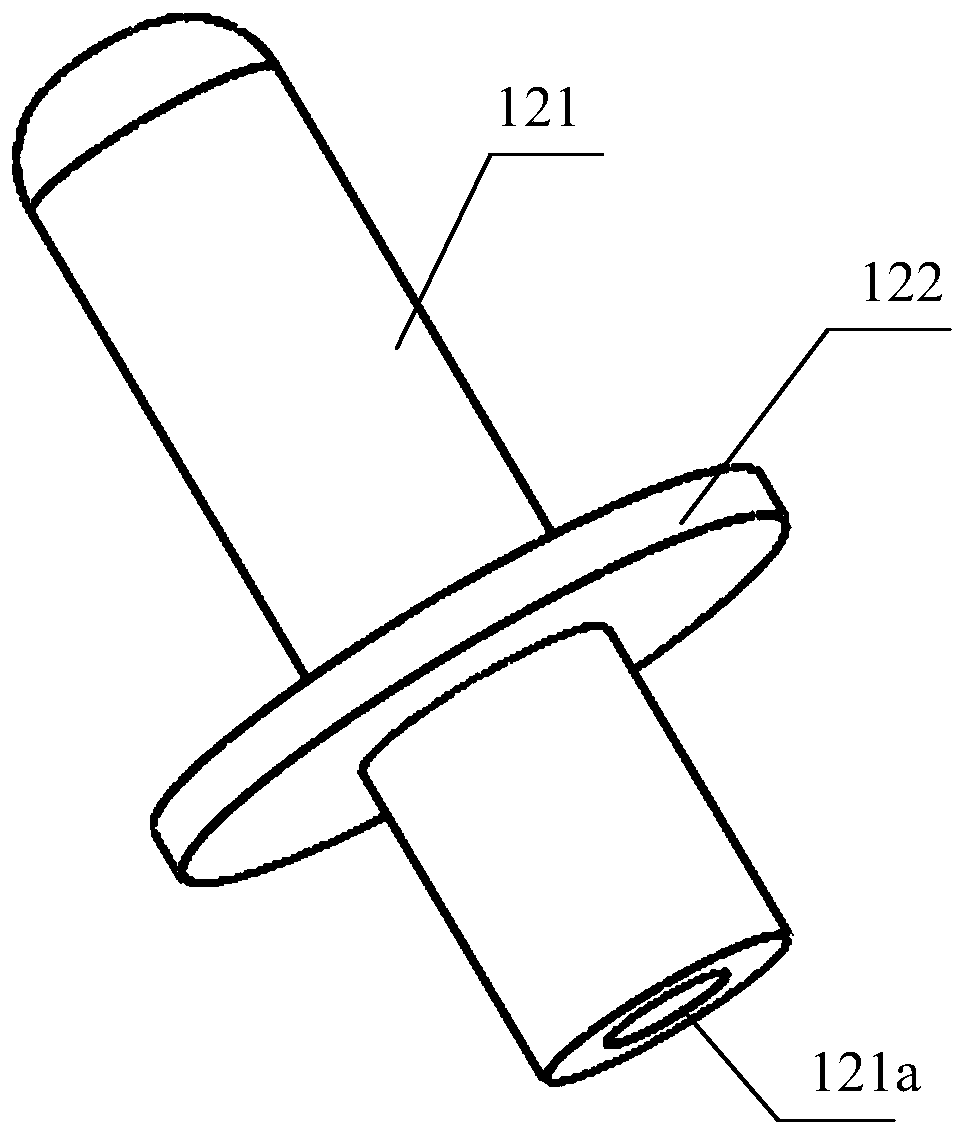

[0074] Such as figure 2 As shown, the center of the base 110 has a stepped first through hole 111, the downturning riveting punch 120 is supported in the first through hole 111 by the elastic device 112, the ultrasonic vibration device 130 is connected to the bottom of the downturning riveting punch 120, and It can drive the riveting punch 120 to hit the top of the base 110;

[0075] Such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com