Household garbage recycling, briquetting and water filtering method and equipment

A technology for household waste and water filtration, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor popularization, poor pressing effect, unable to meet recycling needs, etc., to meet recycling needs, improve pressing effect, and excellent processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

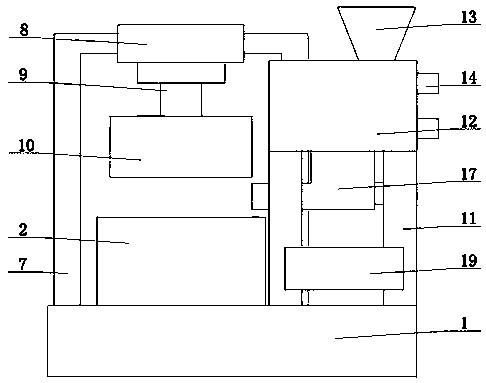

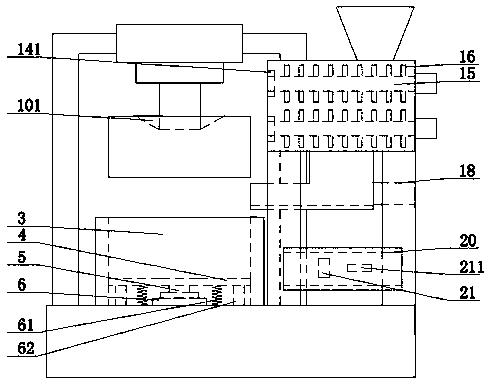

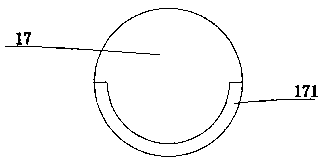

[0028] See Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: a method for recycling and filtering water by pressing blocks of domestic garbage, which includes the following steps:

[0029] Step 1. Domestic garbage enters the inside of the crushing chamber through the feed inlet and is fully crushed. The size of the crushed material after crushing is 0.8-1.8 cubic centimeters;

[0030] Step 2: The crushed material enters the temporary storage pipeline from the crushing chamber, and the filter plate on the inner wall of the temporary storage pipeline filters the crushed material. The filtering time is 3-5 minutes, and then the conveying fan transports the crushed material from the temporary storage pipeline to the pressing tank;

[0031] Step 3. The pressing block presses the crushed material in the pressing tank several times, and the pressing pressure is 8-14t / cm2,

[0032] The pressed density is 7.0-12g / cm3, and a pressed block is obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com