A volume alternating microporous inner surface cavitation strengthening device and processing method

A technology for strengthening the device and the inner surface, which is applied in the field of metal surface treatment to achieve the effects of strong versatility, easy disassembly and cleaning, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

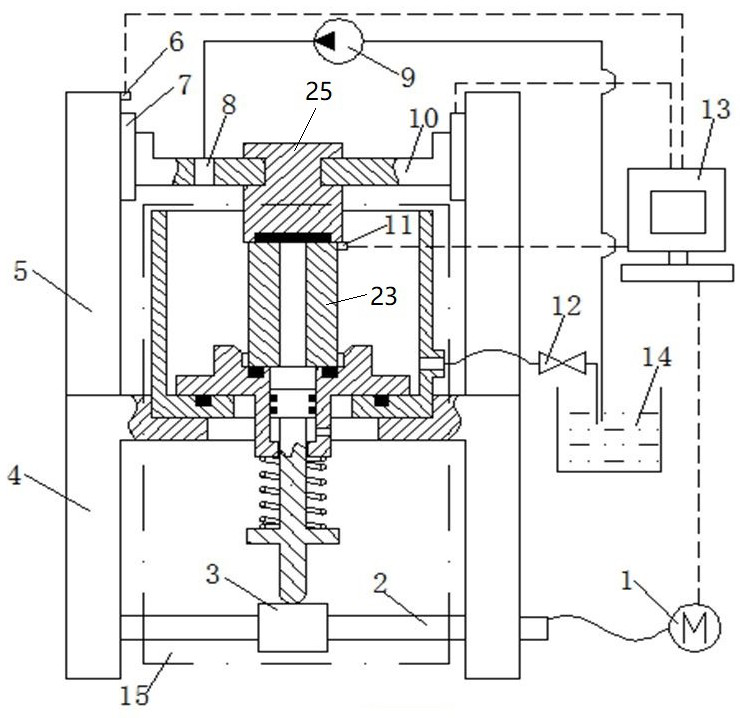

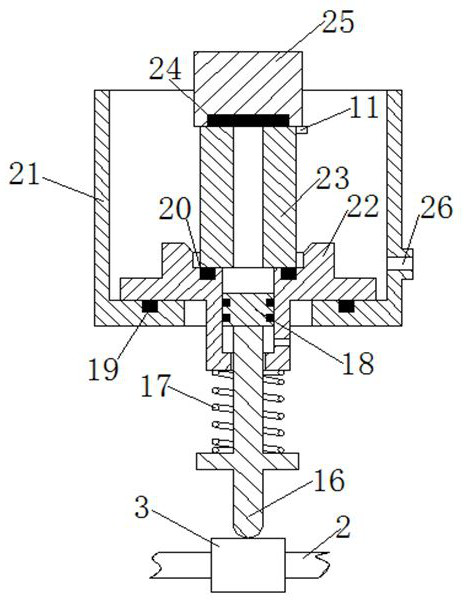

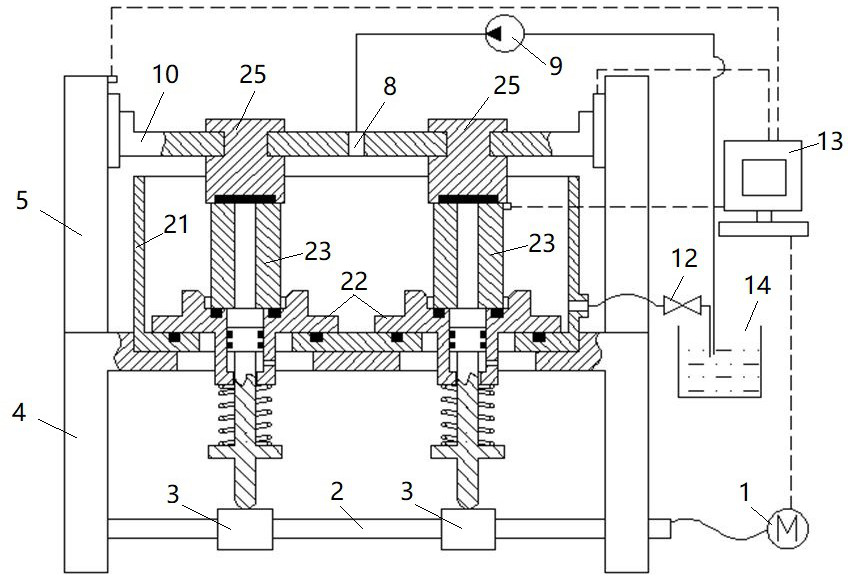

[0020] see figure 1 , The present invention is a volume alternation microporous inner surface cavitation strengthening device with: horizontal table base 4, vertical table base 5, liquid supply system, cavitation generation system 15 and position sensor. The vertical workbench base 5 and the horizontal workbench base 4 are perpendicular to each other, the upper surface of the horizontal workbench base 4 is fixedly connected to the vertical workbench base 5, and the cavitation generation system 15 is fixedly connected to the horizontal workbench base 4 on. The liquid supply system is used to inject liquid into the cavitation generation system 15 , and it includes: a liquid pool 14 , a liquid storage tank 21 , a valve 12 and a liquid pump 9 .

[0021] see figure 1 with figure 2 , the cavitation generation system 15 is used to form cavitation in the micropores to be strengthened, and it includes: a liquid storage tank 21, a drive motor 1, a cam 3, a camshaft 2, a spring 17, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com