Metal strip grinding and descaling system

A metal strip and descaling system technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of poor effect and high cost of descaling system, achieve low manufacturing cost, significant descaling effect, Solve the effect of thick scales on the edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

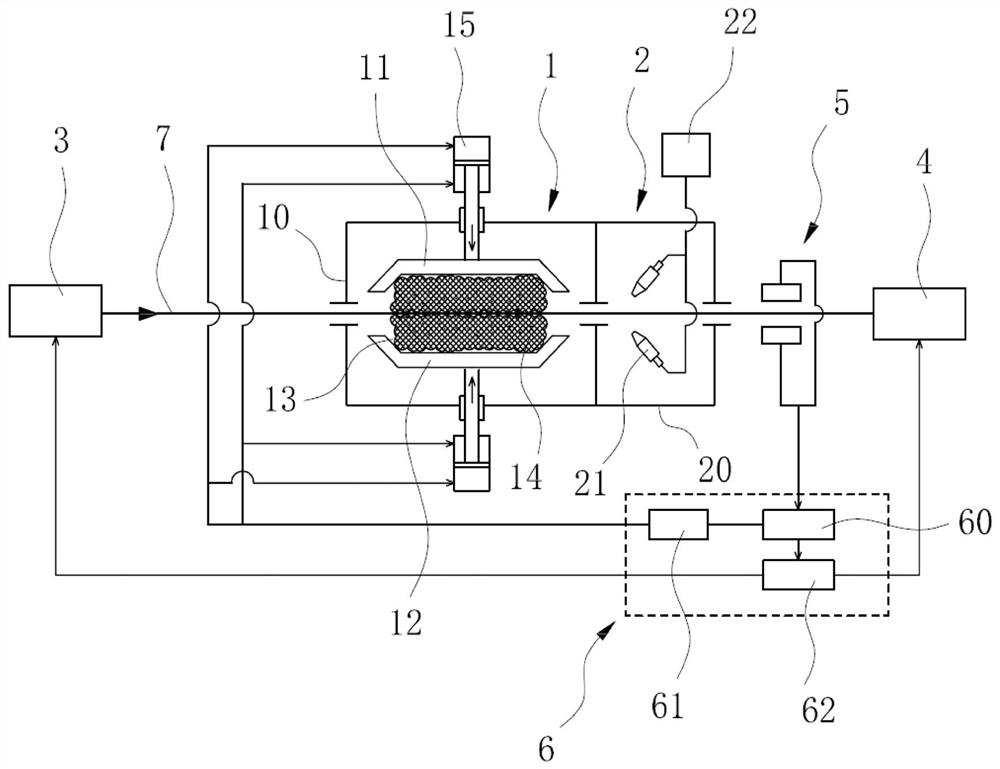

[0031] Such as figure 1 with figure 2 Commonly shown, the metal strip grinding and descaling system includes a descaling device 1 and a strip conveying device.

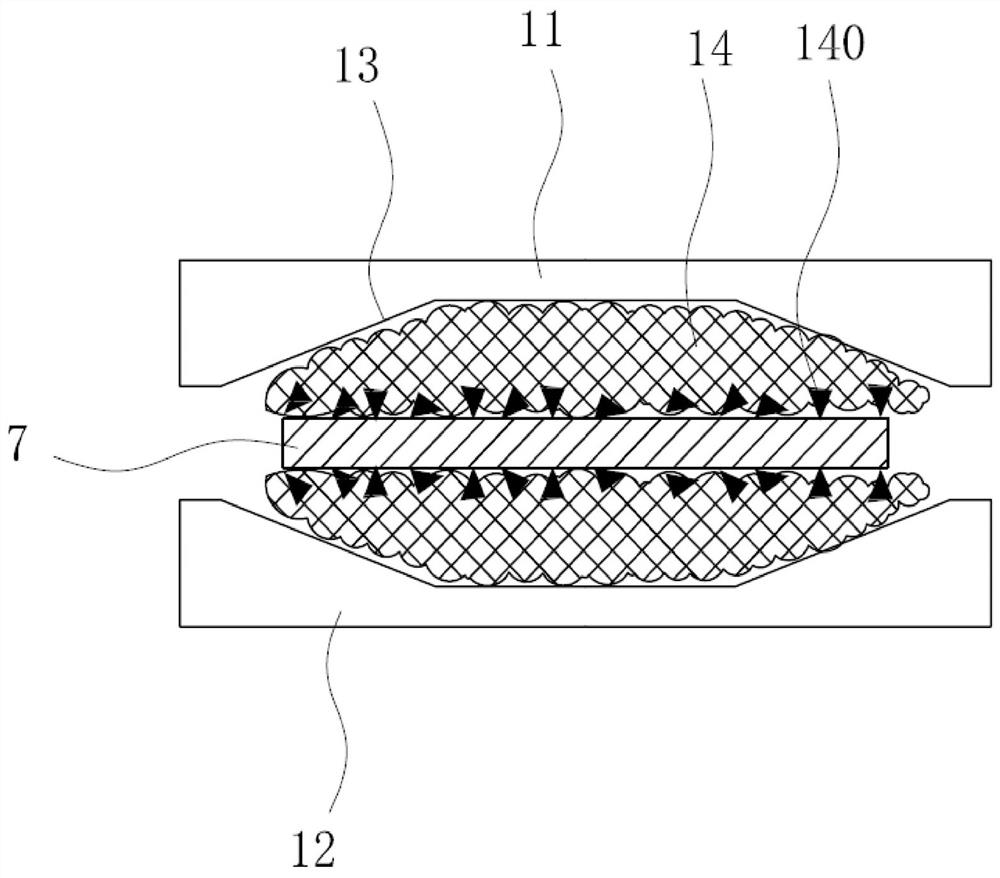

[0032] The descaling device 1 includes a descaling box 10, the two sides of the descaling box 10 are provided with an inlet and outlet, the descaling box 10 is provided with an upper extrusion plate 11 and a lower extrusion plate 12, and the descaling box 10 is provided with a drive upper The driving mechanism 15 that the extrusion plate 11 and the lower extrusion plate 12 move toward or back to each other;

[0033] The driving mechanism 15 is an electric push rod or a cylinder or a hydraulic cylinder controlled by a solenoid valve. Taking the cylinder as an example, two cylinders are respectively fixed on the top and bottom of the descaling box 10 , and a guide sleeve is provided between the drive shaft of the cylinder and the descaling box 10 . The drive shaft of the cylinder above is affixed to the top of the u...

Embodiment 2

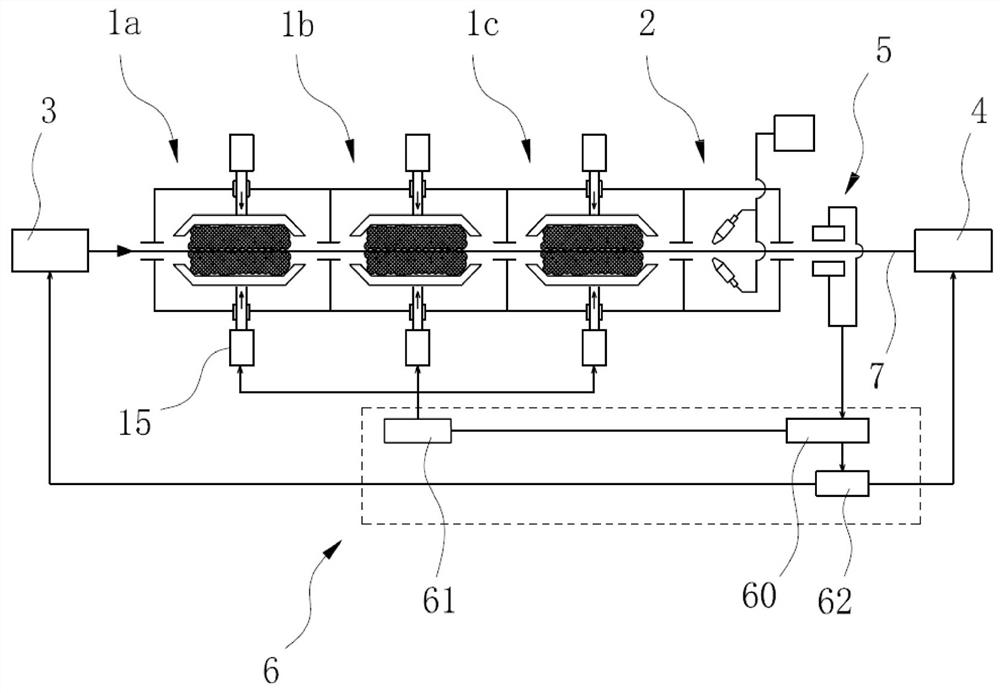

[0047] The difference between this embodiment and Embodiment 1 is that, as image 3 As shown, the descaling device 1 is set as a continuous three-stage structure, which is the first descaling unit 1a, the second descaling unit 1b and the third descaling unit 1c in sequence. The hardware configuration of the three descaling devices 1 is the same, And the extrusion force of each descaling device 1 can be adjusted independently.

[0048] The metal fiber mesh body 14 used in the first descaling unit 1a has a single equivalent diameter of 400-500 μm, and the particle size of the abrasive 140 filled between the pores is 400-600 μm. The material is high-carbon cast steel grit, HRC>60 ;The extrusion force of the clamping metal strip 7 is 2.0~3.0MP metal strip grinding and descaling system; the function of the first descaling unit 1a is to realize the destruction of the surface scale layer and the treatment of large scales; after the first descaling After the unit 1a is processed, mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com