Ceramic tile screeder and technology for laying and pasting ceramic tiles through same

A leveler and ceramic tile technology, which is applied in the direction of architecture and building structure, can solve the problem that adjacent tiles are difficult to keep on the same plane, and achieve the effect of solving uneven paving flatness, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

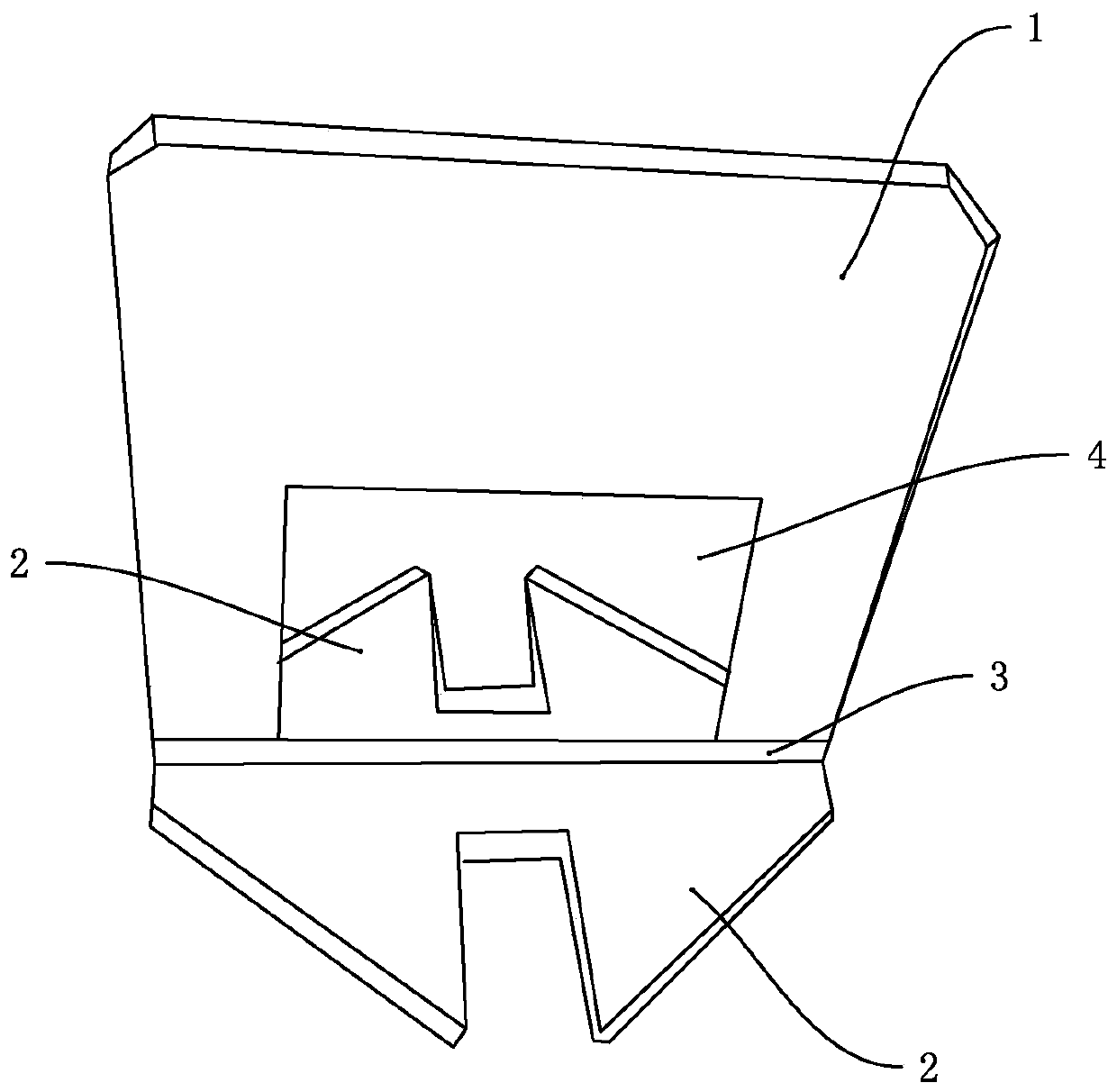

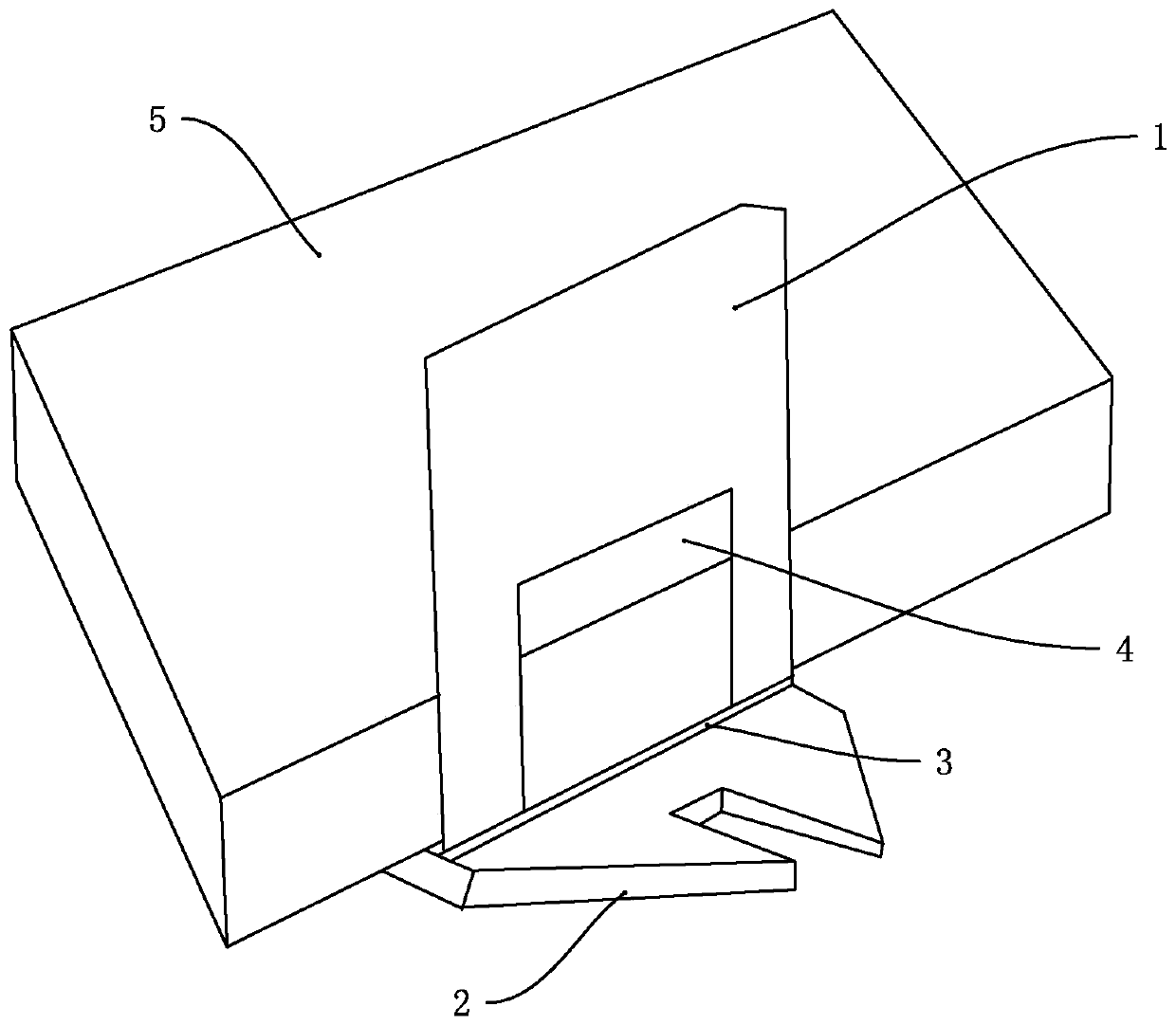

[0027] The first embodiment, such as Figure 1 to Figure 3 As shown, a ceramic tile leveler comprises a vertical plate 1, and horizontal plates 2 perpendicular to the vertical plate 1 are respectively extended on both sides of the bottom of the vertical plate 1, and the horizontal plate 2 and the vertical plate 1 A fold 3 is stamped at the joint, and a wedge opening 4 is opened in the middle of the vertical plate 1 .

[0028] Such as Figure 1 to Figure 3 As shown, when using the present invention to lay tiles 5, the vertical plate 1 is positioned between the gaps between adjacent tiles 5, the two horizontal plates 2 are respectively positioned on the lower surface of the adjacent tiles 5, and the external wedge 6 is inserted into the wedge opening 4 and The horizontal surface of the external wedge 6 is pressed on the upper surface of the adjacent ceramic tile 5, and the upper surface of the adjacent ceramic tile 5 is pressed by the horizontal surface of the wedge 6, so that ...

no. 2 example

[0034] Second embodiment, such as Figure 1 to Figure 5 As shown, a process of laying tiles using a tile leveler, including:

[0035] Step 1, the lower surfaces of the tiles 5 are respectively coated with concrete, and the tiles 5 are attached to the ground or the wall, and the two horizontal plates 2 of the tile leveler are respectively inserted into the lower surfaces of the adjacent tiles 5, and the vertical plate 1 is inserted into the adjacent tiles 5 gap between

[0036] Step 2, the wedge 6 is inserted into the wedge opening 4, and the horizontal plane of the wedge 6 is in contact with the upper surface of the adjacent tile 5;

[0037] Step 3, the wedge 6 is compressed in the wedge mouth 4, so that the horizontal surface of the wedge 6 is pressed against the upper surface of the adjacent ceramic tile 5, and the compression time is T hours;

[0038] Step 4, after the concrete is bonded to the ground or the wall, take out the wedge 6;

[0039] Step 5, break off the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com