Method for paving recombinant material slab and device thereof

A technology of recombined wood and slabs, which is applied to wood processing appliances, household components, flat products, etc., can solve problems such as uneven paving, and achieve the effects of wide equipment adaptability, low energy consumption, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

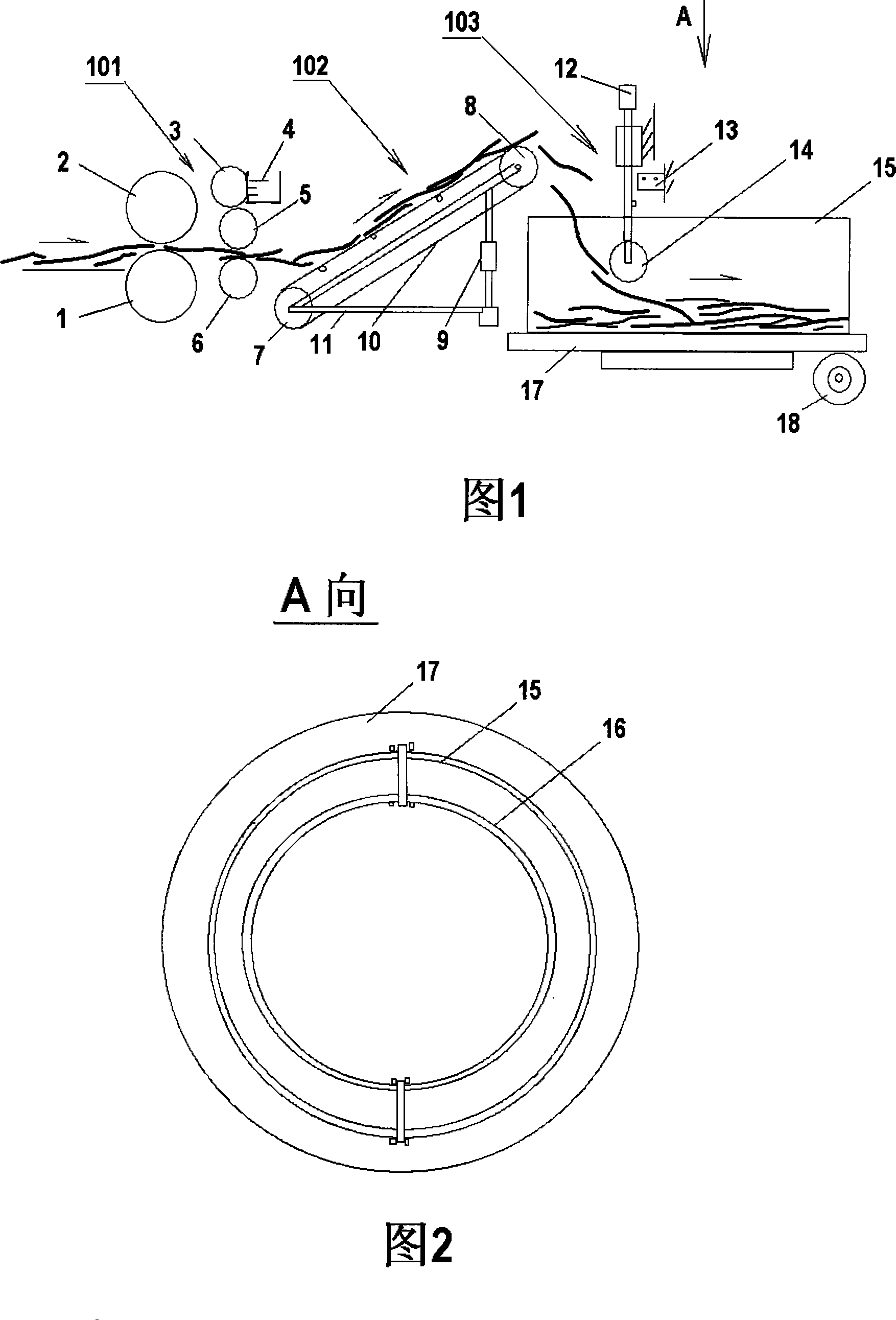

[0016] Provide specific embodiments below in conjunction with accompanying drawings.

[0017] The embodiment of the present invention is a device for laying two slabs at a time, specifically as figure 1 , figure 2 shown. The raw materials of heavy wood slabs such as crop stalks, fruit branches, and branches after being decomposed and dried are manually fed into the feeding and sizing device 101. Carry out gluing with lower rubber roller 6, and the glue solution in the glue tank 4 is stuck on the rubber roller by getting the rubber roller 3 and rolling. The raw material after gluing falls on the belt conveyor 102, and is sent to the rotary paving device 103 by the conveyor belt 10, and falls to the space between the inner material guide plate 16 and the outer material guide plate 15 as the rotary disc 17 rotates. The raw material is compacted by the gravity compaction wheel 14, and when it reaches the specified height, the material belt height alarm device 13 sends out an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com