Bearing assembly

A technology of bearing components and bearings, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of reduced service life and limited floating distance of spherical roller bearings at the floating end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

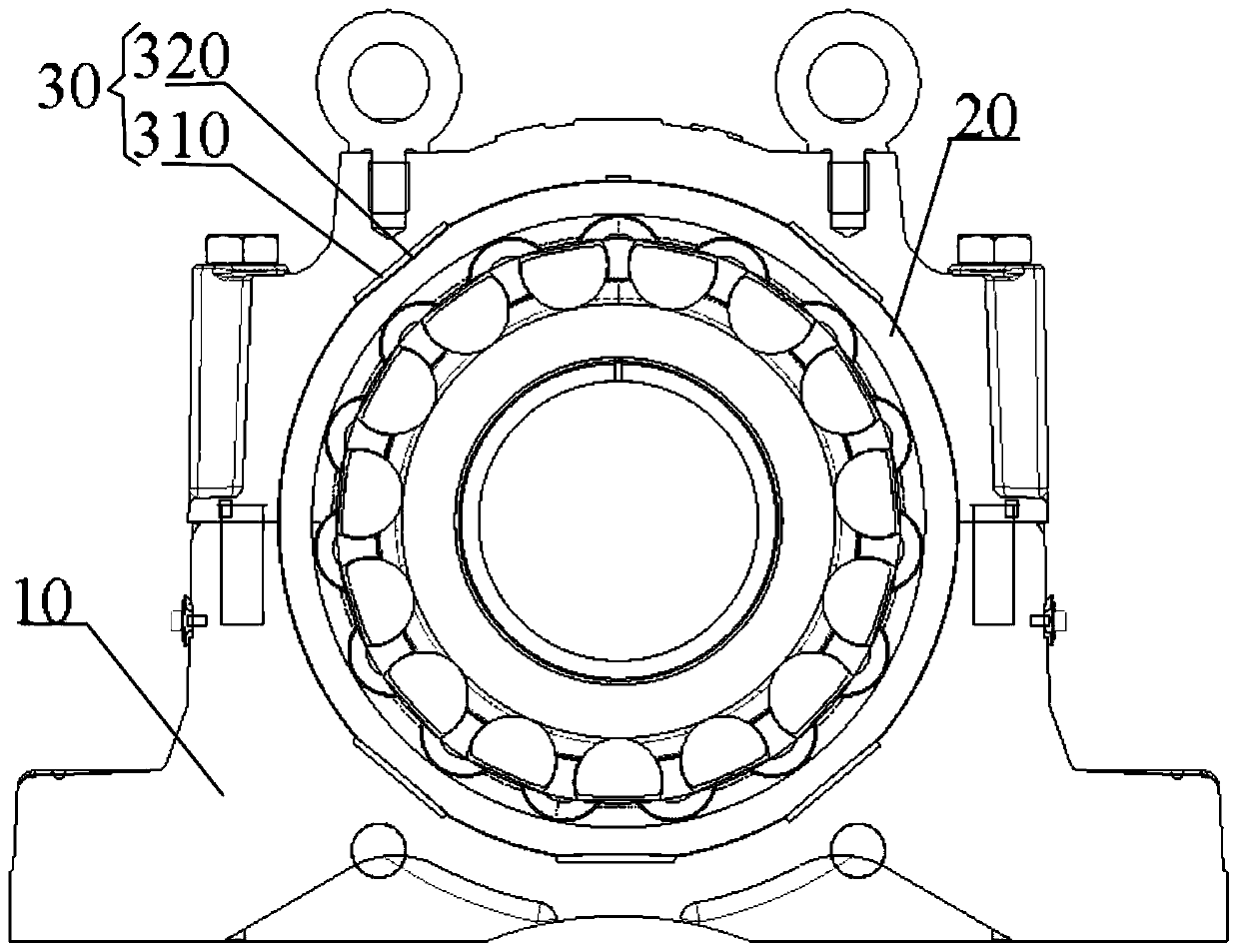

[0037] It can be known from the background technology that the outer ring of the non-locating bearing is in direct surface contact with the hole of the bearing housing. In the case of deformation of the shaft, there will be relative movement between the two in the axial direction, resulting in a large friction force, which limits the floating distance and reduces the life of the non-locating bearing.

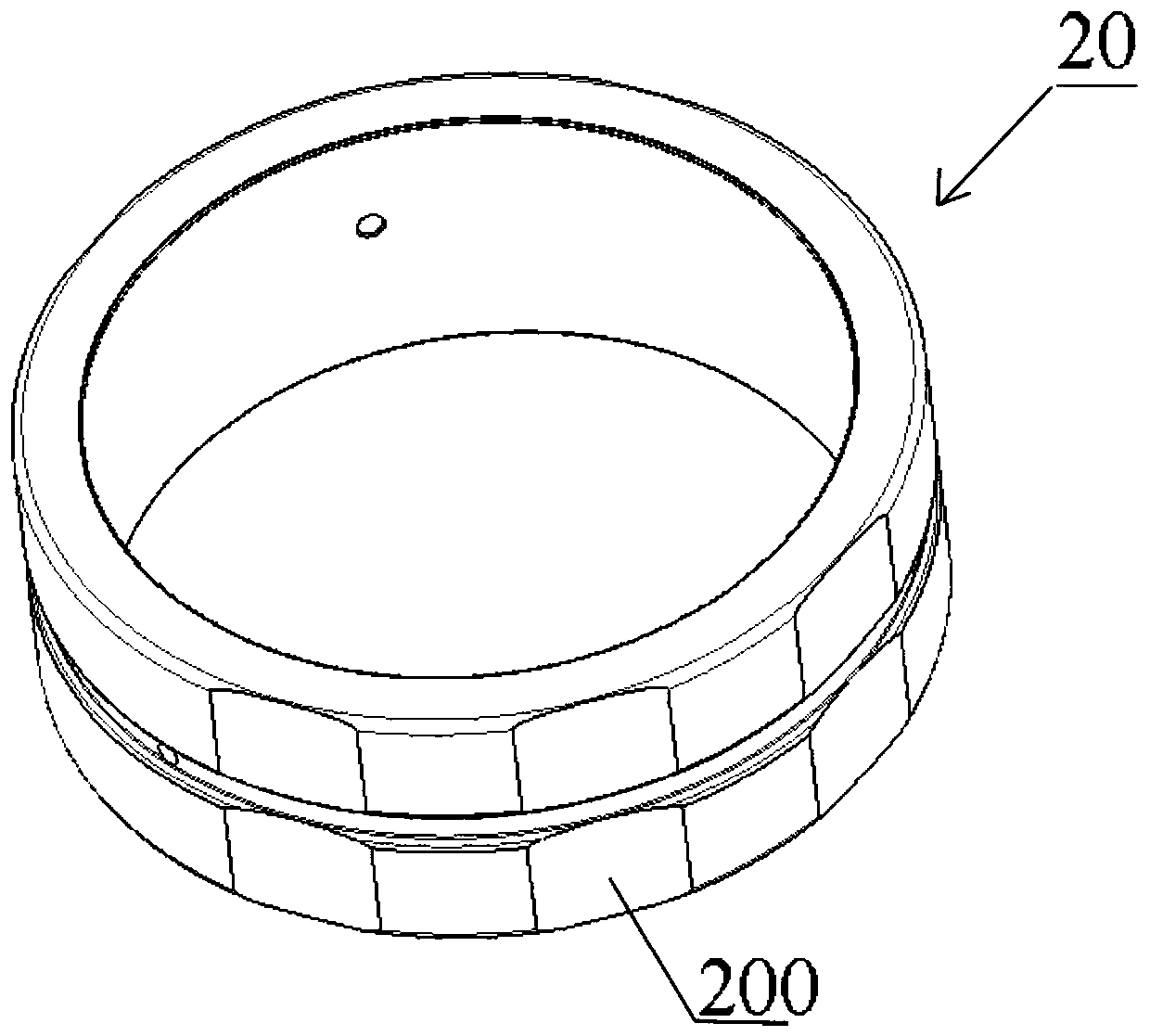

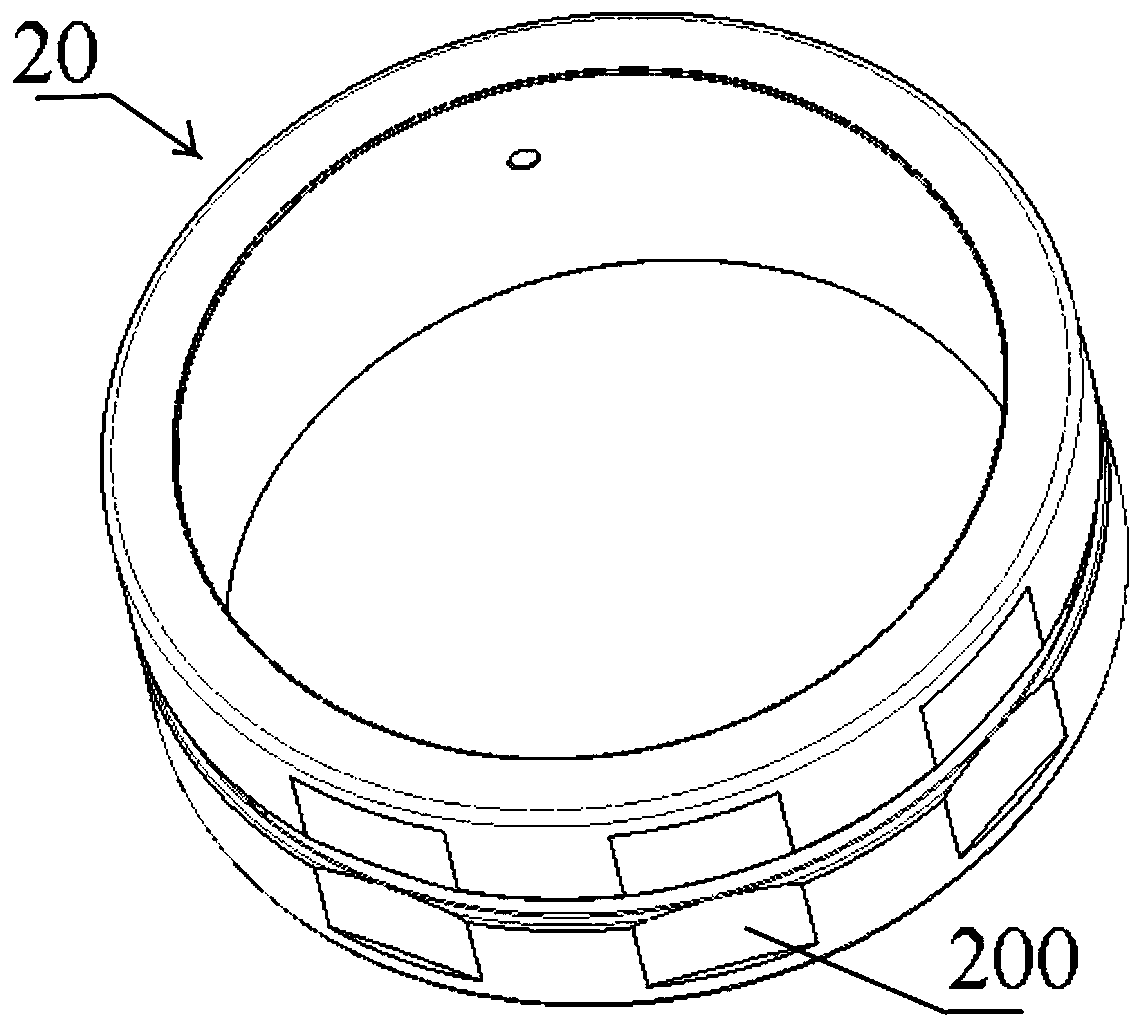

[0038] In order to improve the floating distance and service life of the non-locating bearing, the embodiment of the present invention provides a bearing assembly, by fixing wear-resistant parts on the hole wall of the bearing seat, and extending along the axial direction on the circumferential surface of the bearing outer ring. The groove of the outer ring of the bearing, and the wear-resistant parts are embedded in the groove of the outer ring of the bearing. When the shaft expands due to heat, the outer ring of the bearing is driven by the shaft to move relative to the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com