Manufacturing method of simple, quick, temperature-adjustable and timing tap hot water steam device

A technology of hot water steam and manufacturing method, which is applied in the direction of steam generation method, steam generation, control system, etc., which can solve the problems of small water output, large gas consumption, and large volume, and achieve the effect of fast speed and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

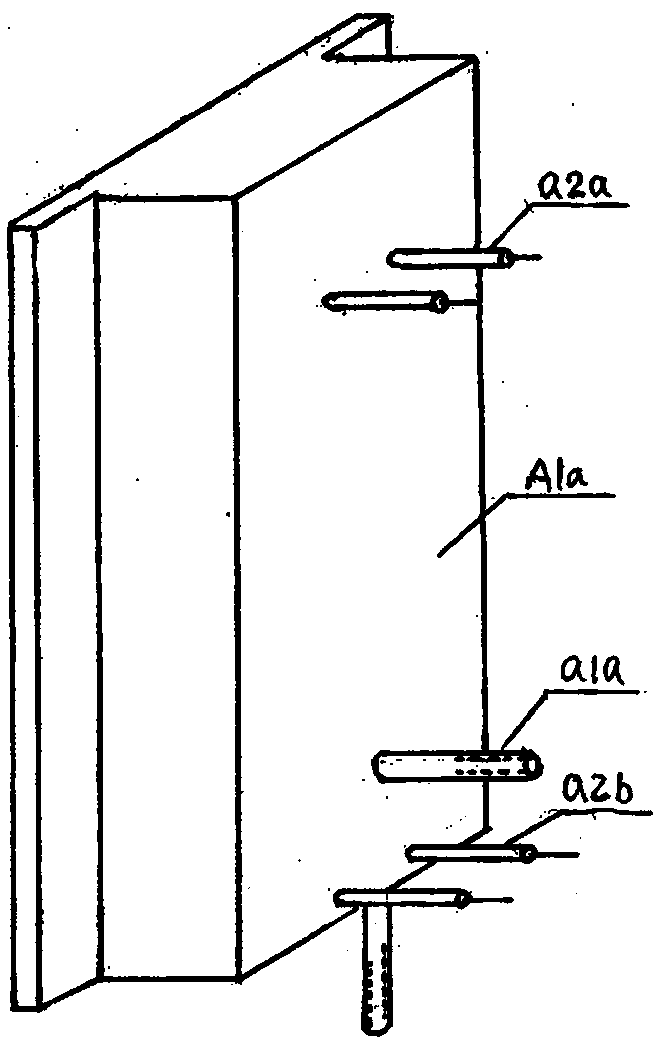

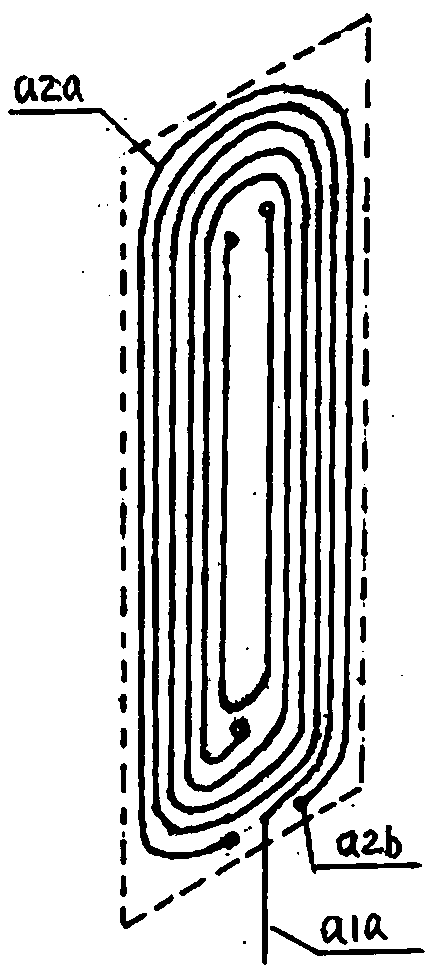

[0060] Example 1: A simple and fast temperature-adjustable timing tap hot water steam device. Manufacturing method:

[0061] 1. The two ends of the bottom are round, the middle is rectangular, the outer end is drawn out from the bottom semicircle center plane, the inner end is drawn out vertically, with a threaded interface, a flat spiral stainless steel water pipe a1a, a1a is drawn out from the bottom semicircle center and The length of the unthreaded part bent vertically upwards inside is about 5 cm, and the length of the part with external thread is about 5 cm. The straight pipe made of a1a is 2--4 points of stainless steel pipe, 6--30 meters long;

[0062] 2. Make two electric heating tubes a2a and a2b whose bottoms are square and round, and the two ends are vertically upwards, which can be connected and dry-burned; a2a is closely attached to the inside of a1a, and a2b is tightly sleeved outside of a1a. cm, the height of the vertically upward curved parts at both ends of a...

Embodiment 2

[0067] Example 2: Manufacturing method of B-type simple, fast, temperature-adjustable and timing tap hot water steam device

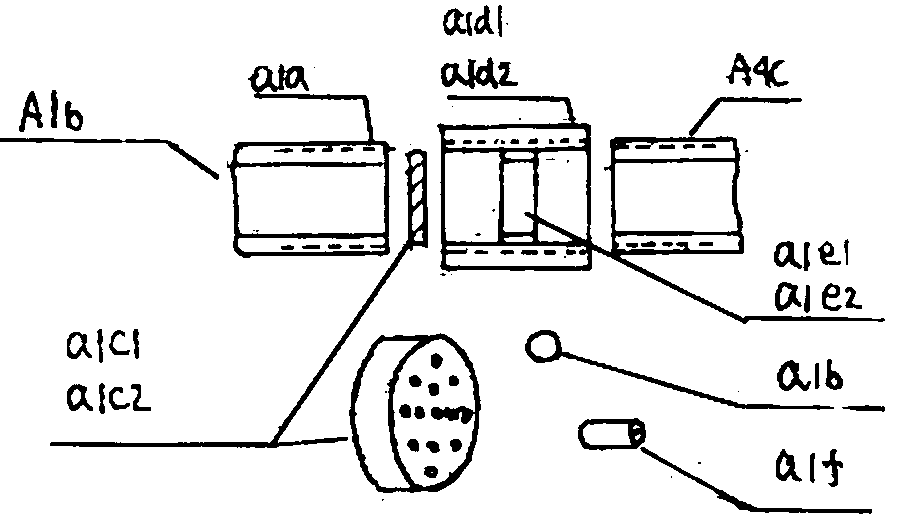

[0068] 1. The two ends of the cross-section are round, the middle is narrow rectangle, the two ends are vertically bent up and down, and there is a spiral-shaped stainless steel water pipe b1a with external thread interface, and the b1a straight pipe is 2--4 points stainless steel pipe 6— 30 meters long, b1a is placed vertically or horizontally, the unthreaded part is 5 cm from both ends vertically upwards and downwards, and the part with external thread is 5 cm each, and two or four U-shaped electric heating tubes are placed horizontally in the spiral tube;

[0069] 2. Make stainless steel balls b1b, bead baffles b1c1, b1c2, internal threaded pipes b1d1, b1d2 and their built-in short 4 cm short straight pipes b1e1, b1e2, b1b, b1c1, b1c2, b1d1, b1d2, b1e1 , b1e2 are combined into hot water steam element B1b;

[0070] 3. Make U-shaped electric heating t...

Embodiment 3

[0074] Example 3. The manufacturing method of C-type simple, fast, temperature-adjustable and timing tap hot water steam device

[0075] 1. The cross-section is circular, the two ends are vertically bent up and down, and there is a stainless steel spiral water pipe c1a with external thread interface, c1a is 2-4 branch pipes, about 6-30 meters long, c1a can be placed vertically or horizontally; The curved parts of the upper and lower unthreaded parts at both ends are about 5 cm long, and the upper and lower parts with external threads are about 5 cm long;

[0076] 2. Make U-shaped vertically upward bending electric heating tubes c2a1--c2a4 that can be wired and dry-burned;

[0077] 3. Make stainless steel beads c1b that can be poured in and out of stainless steel pipes, can pass water but not bead pipe end baffles c1c1, c1c2, internal threaded pipes c1d1, c1d2 and their built-in slightly short, not tight, not loose straight pipes c1e1, c1e2; c1b, c1c1, c1c2, c1d1, c1d2, c1e1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com