Near-field tunnel blasting vibration dynamic strain testing method for tunnel under construction

A blasting vibration and testing method technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, etc., can solve the problems of large blasting vibration, difficult to zero dynamic strain value, interference, etc., to reduce vibration friction and blasting vibration Shock, the effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

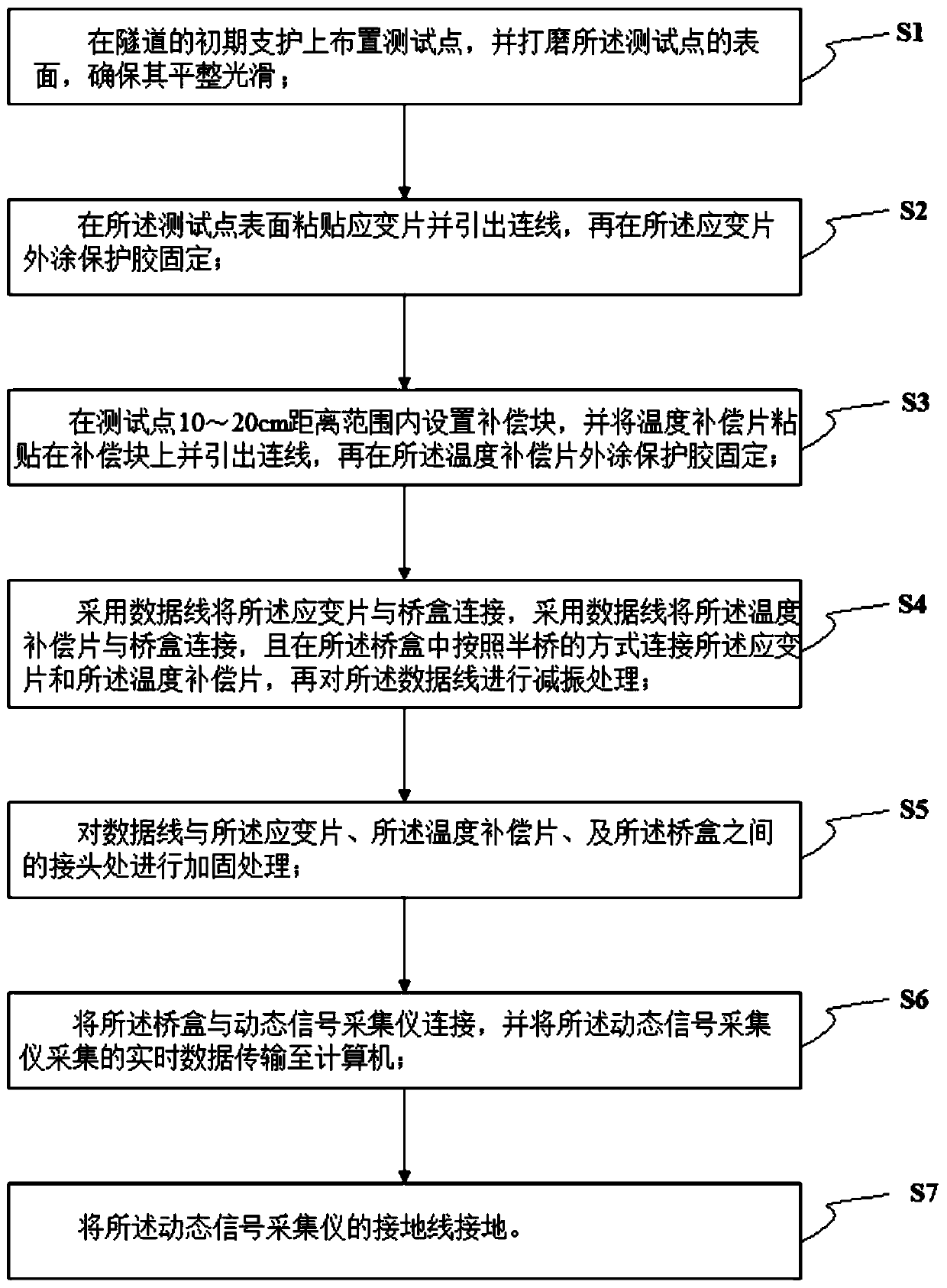

Method used

Image

Examples

Embodiment 1

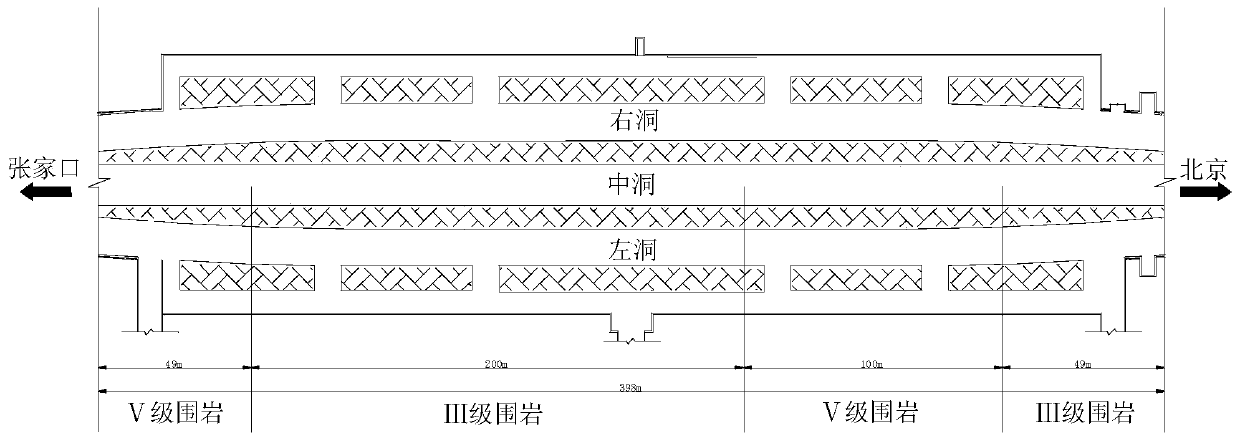

[0067] The Beijing-Zhangjiakou high-speed railway in this embodiment is a key construction project planned and implemented by the state, and it is also a supporting project for Beijing-Zhangjiakou to jointly host the Olympic Games in 2022. The Badaling Great Wall Station of the Beijing-Zhangjiakou High-speed Railway is currently the deepest buried high-speed railway underground station in China. It is located under the Badaling Great Wall Scenic Area and in the New Badaling Tunnel.

[0068] see figure 2 , figure 2 It is a division diagram of the surrounding rock grades of the three-hole separation section in Example 1 of the present invention. The platform layer of Badaling Great Wall Station is a separated section with three tunnels. It is composed of three tunnels, the main line cavern and the departure line caverns on both sides. Monzogranite, the surrounding rock grades are mainly grade III and grade V.

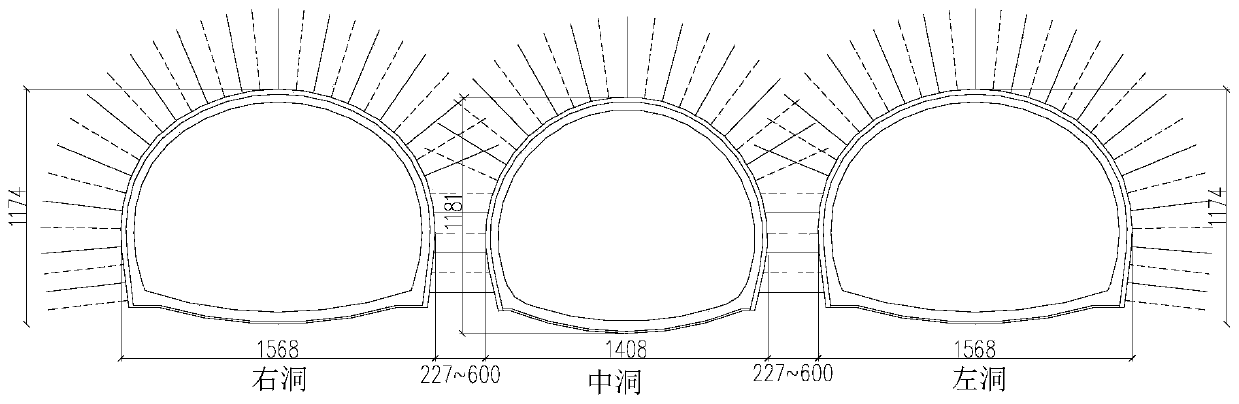

[0069] see image 3 , image 3 It is a cross-sectional view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com