Thermal power plant risk pre-control management system based on virtual physical information fusion technology

A management system and physical information technology, applied in the field of thermal power plant risk pre-control management system, can solve the problems of lack of globalization, whole process, precision, limited video monitoring or access control system, and inability to realize risk pre-control management. To achieve the effect of preventing unsafe accidents in power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

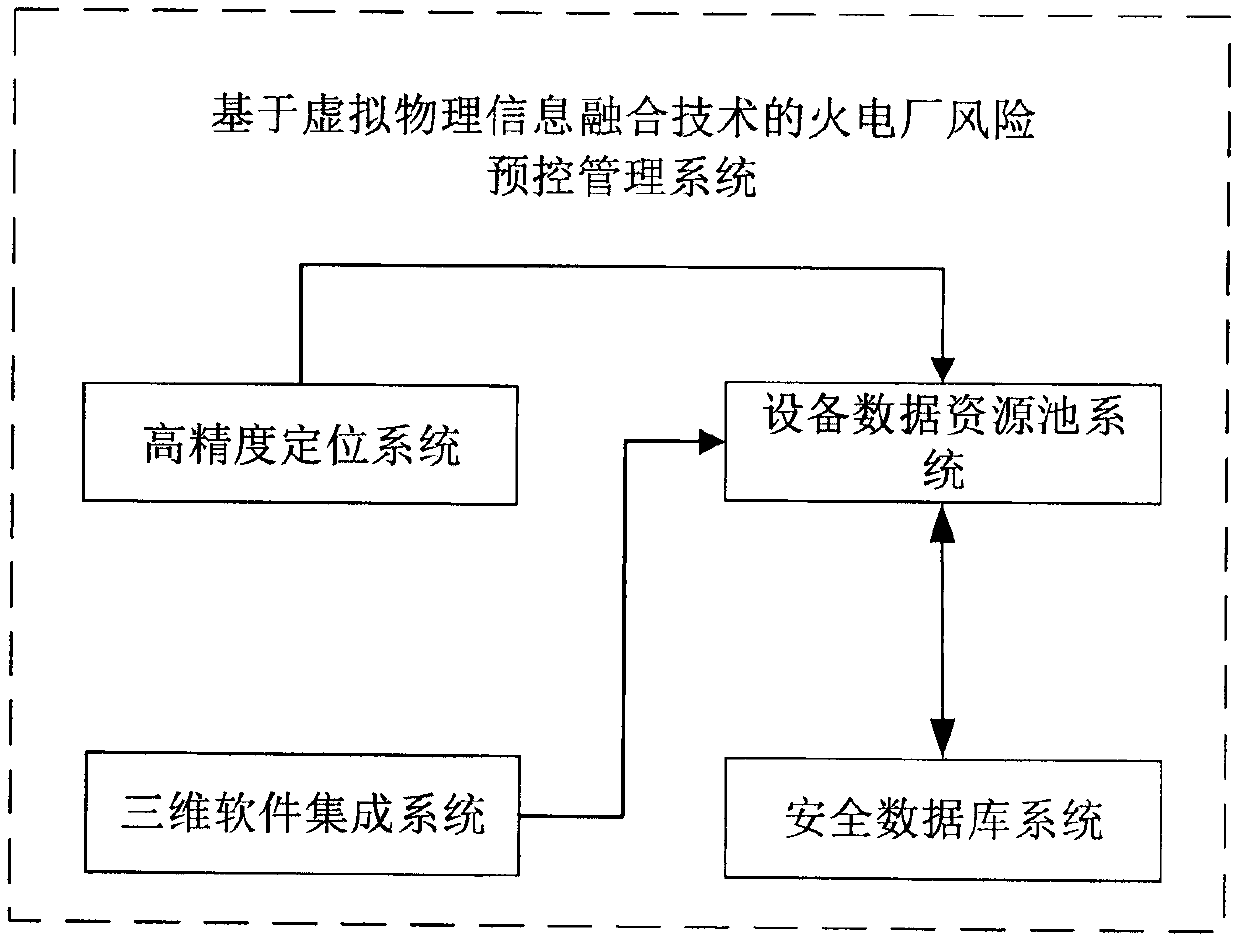

[0016] The structure of the risk pre-control management system is as follows: figure 1 As shown, it includes high-precision positioning system, 3D software integration system, equipment data resource pool system, and active safety database system. The risk pre-control management system is divided into three layers. The high-precision positioning system and the three-dimensional software integration system belong to the data acquisition layer, the active safety database system belongs to the data sending layer, and the equipment data resource pool system belongs to the data storage layer.

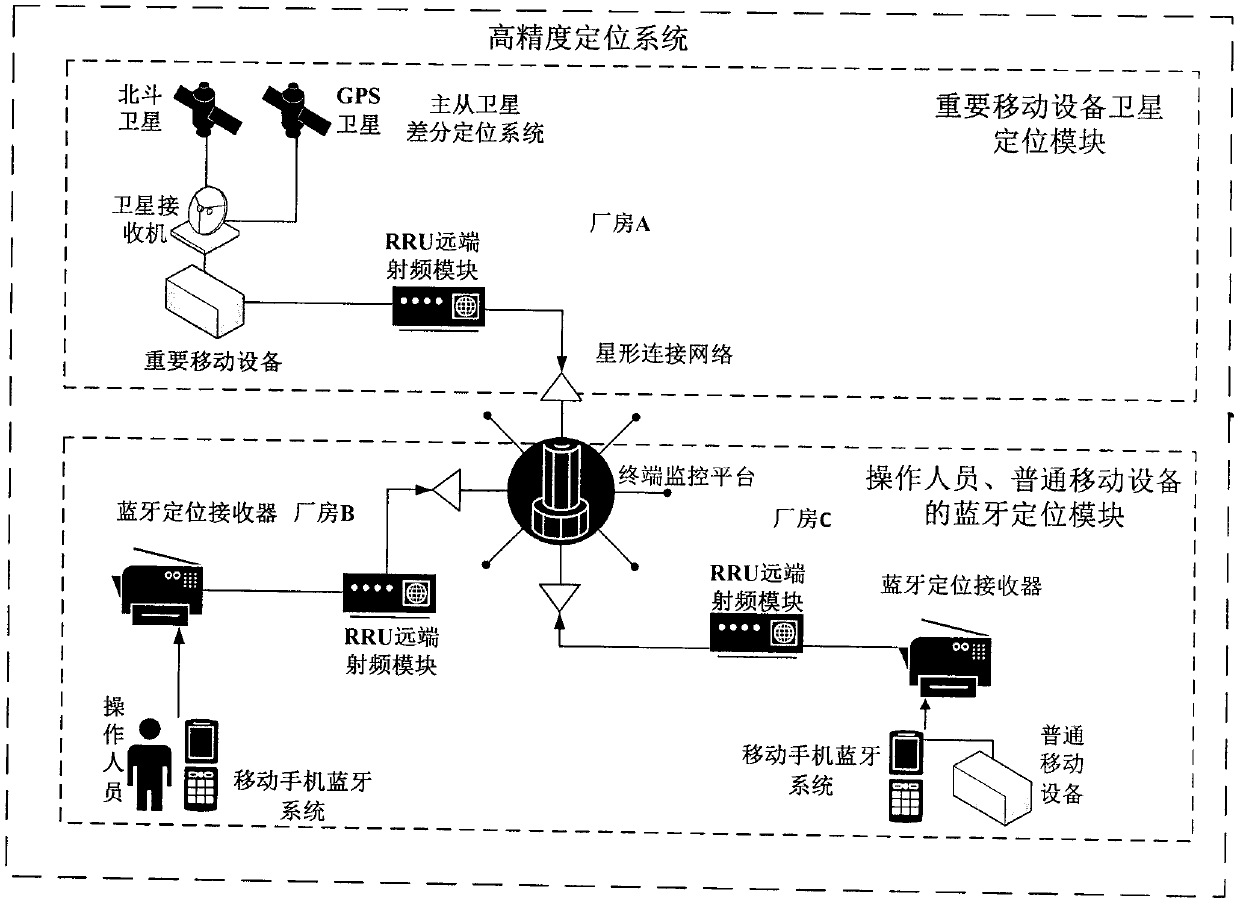

[0017] figure 2 It is the structural diagram of the high precision positioning system. The high-precision positioning system mainly includes satellite receivers, mobile phone Bluetooth systems, Bluetooth positioning receivers, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com