Pet silicone oil film recycling device and method for producing molten carbonate fuel cell diaphragm

A molten carbonate and fuel cell technology, applied in the field of battery diaphragm processing, can solve the problems of non-reusability, low recycling rate, uneven and safe manual oil brushing, etc., to achieve the effect of even brushing oil and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

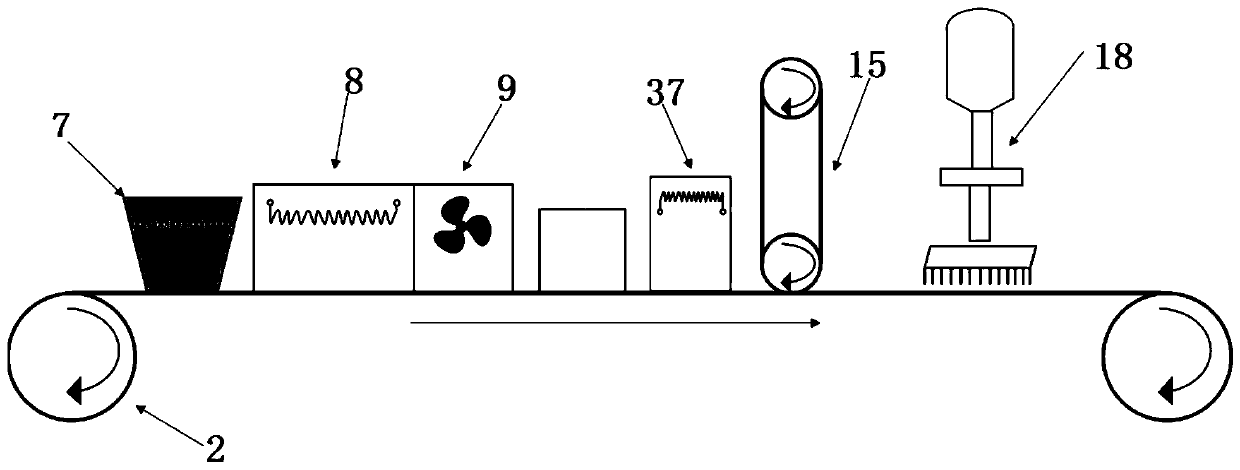

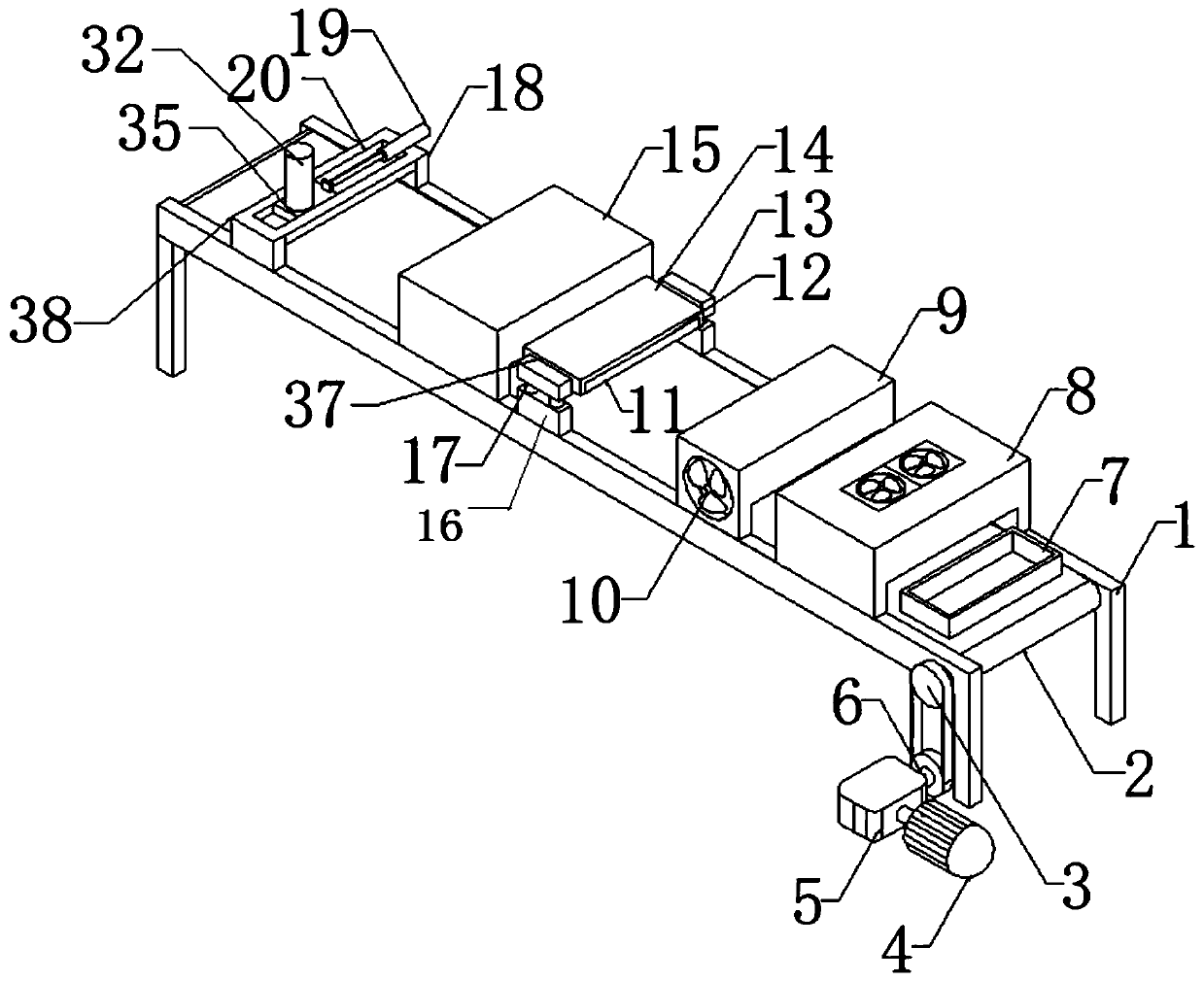

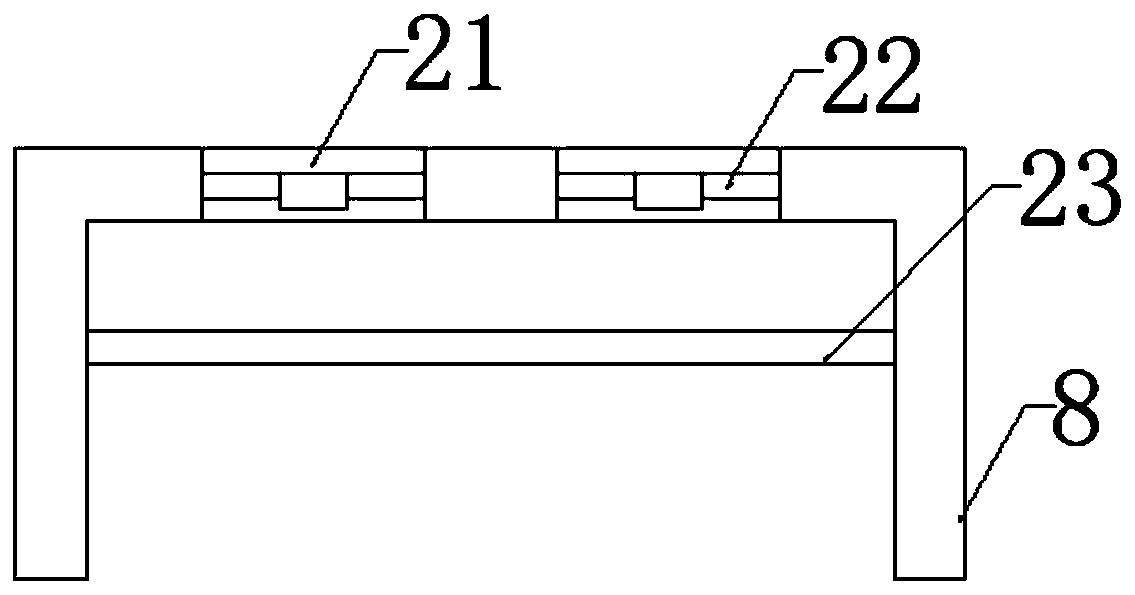

[0025] See Figure 1-5 As shown, the present invention provides a pet silicon oil film recovery and reuse device for producing molten carbonate fuel cell membranes. It includes a conveyor frame 1. One end on both sides of the inner wall of the conveyor frame 1 is fixed with a first rotating shaft and two second shafts. One end of a rotating shaft is rotatably connected with two ends of the driving roller 2, and the other end of one of the first rotating shafts passes through one of the transmission frames 1 and is rotatably connected with one end of the first sprocket 3, and the first sprocket 3 is connected to the first sprocket through a chain. The two sprockets 6 are in transmission connection, one end of the second sprocket 6 is fixedly connected to the output end of the reduction box 5, the input end of the reduction box 5 is fixedly connected to the output end of the motor 4, and the driving roller 2 is connected to the driven roller by a belt. , And the two ends of the d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap