Method for punching flexible circuit board and flexible circuit board

A flexible circuit board and hole-cutting technology, which can be used in circuit bendable/stretchable parts, printed circuits, and printed circuit manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

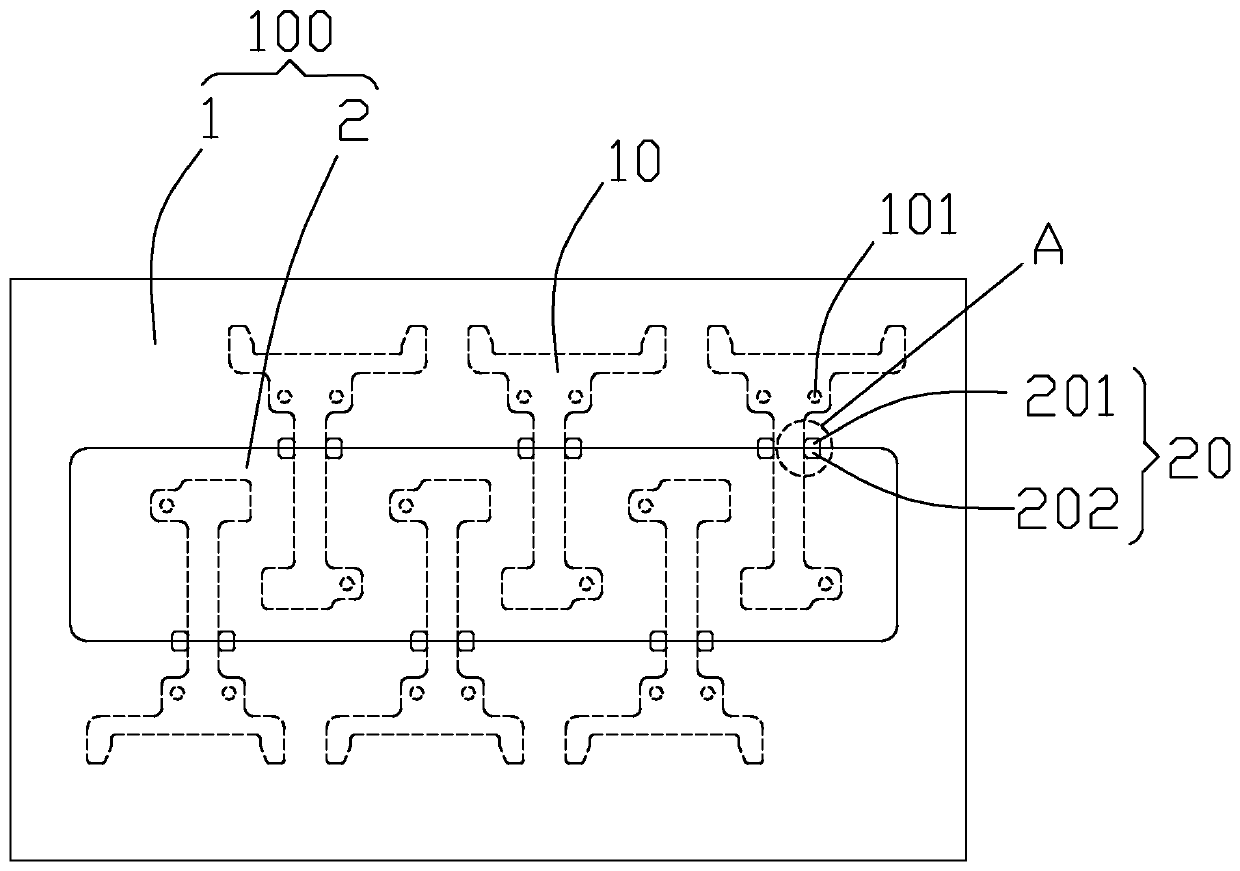

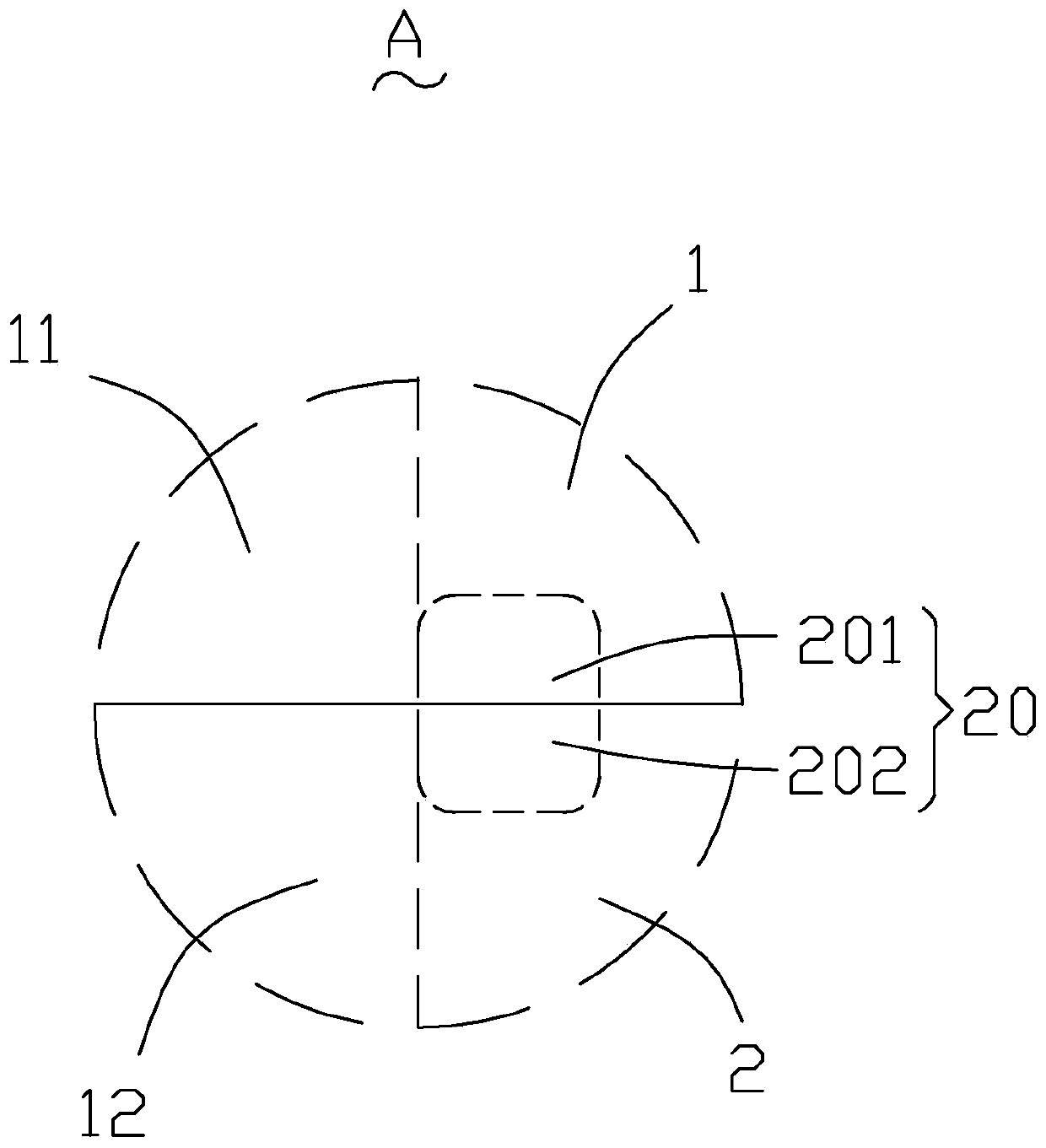

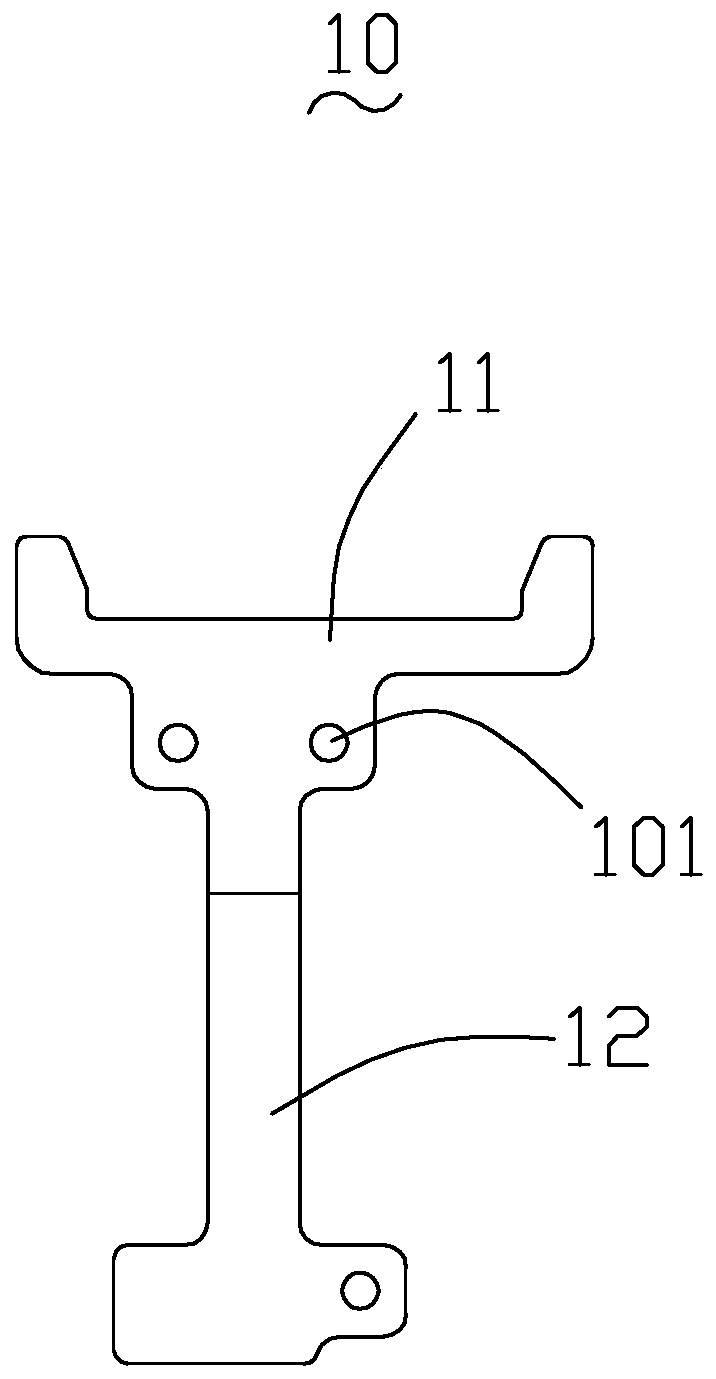

[0028] Attached below Figure 1-2 and embodiments to further illustrate the present invention.

[0029] see Figure 1-Figure 4 , the flexible circuit board 10 includes a flexible circuit board body 11 and a reinforcing layer 12 attached to the flexible circuit board body 11, the reinforcing layer 12 is used to strengthen the strength of the main part of the flexible circuit board body 11, and the semi-finished product 100 of the flexible circuit board includes The substrate 1 of the flexible circuit board body 11 formed by punching and the reinforcing film 2 attached on the substrate 1 for punching and forming the reinforcing layer 12 have height differences between the reinforcing film 2 and the substrate 1 . The flexible circuit board 10 is provided with inner holes 101, and several inner holes 101 are located on the areas on the flexible circuit board 10 that need reinforcement, and some inner holes 101 are located on the areas on the flexible circuit board 10 that do not ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap