Inductive AOI dispenser

A glue dispensing machine and glue dispensing mechanism technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of time-consuming and laborious, and achieve the effects of improving conveying efficiency, compact structure, improving operation accuracy and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

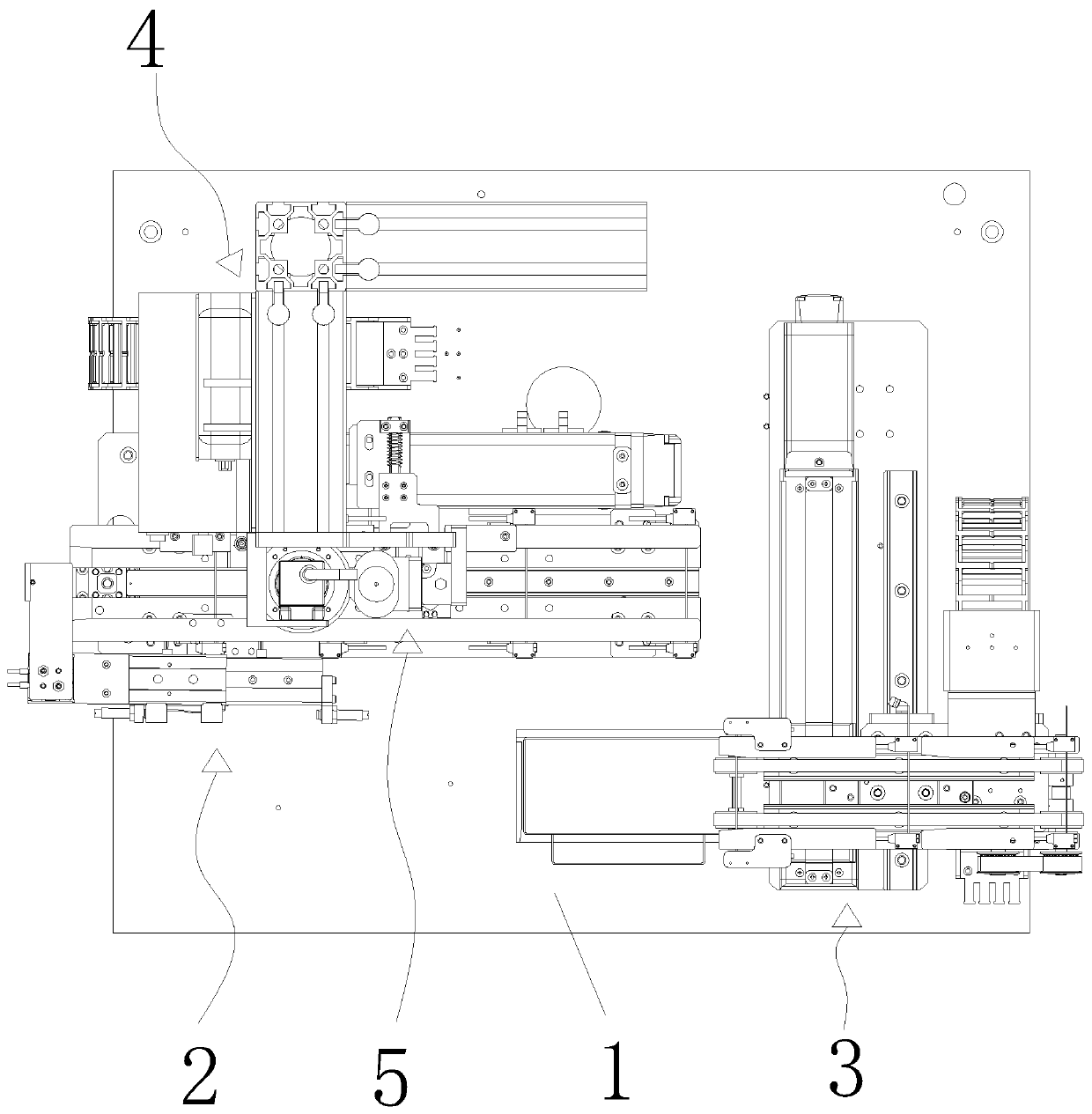

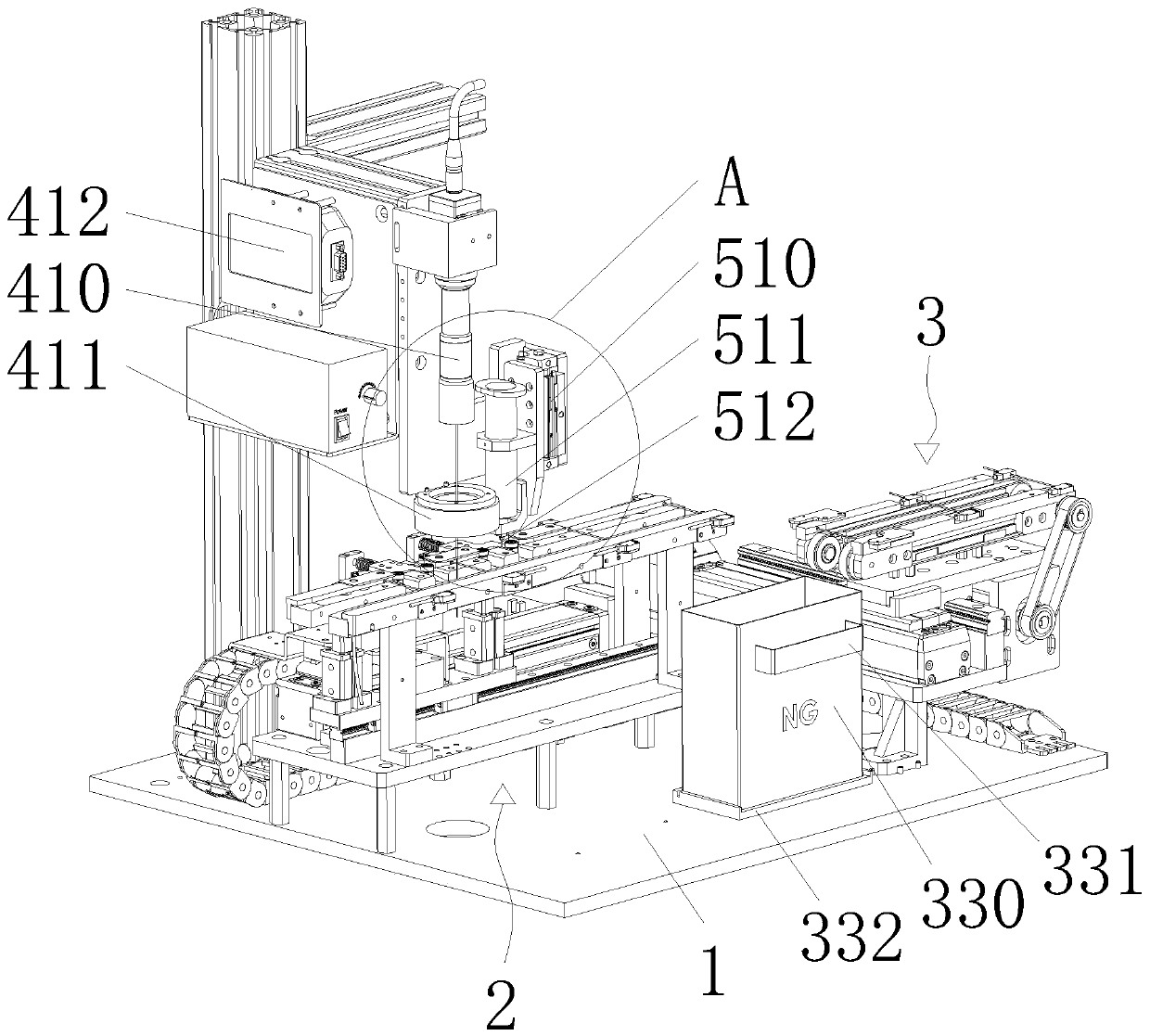

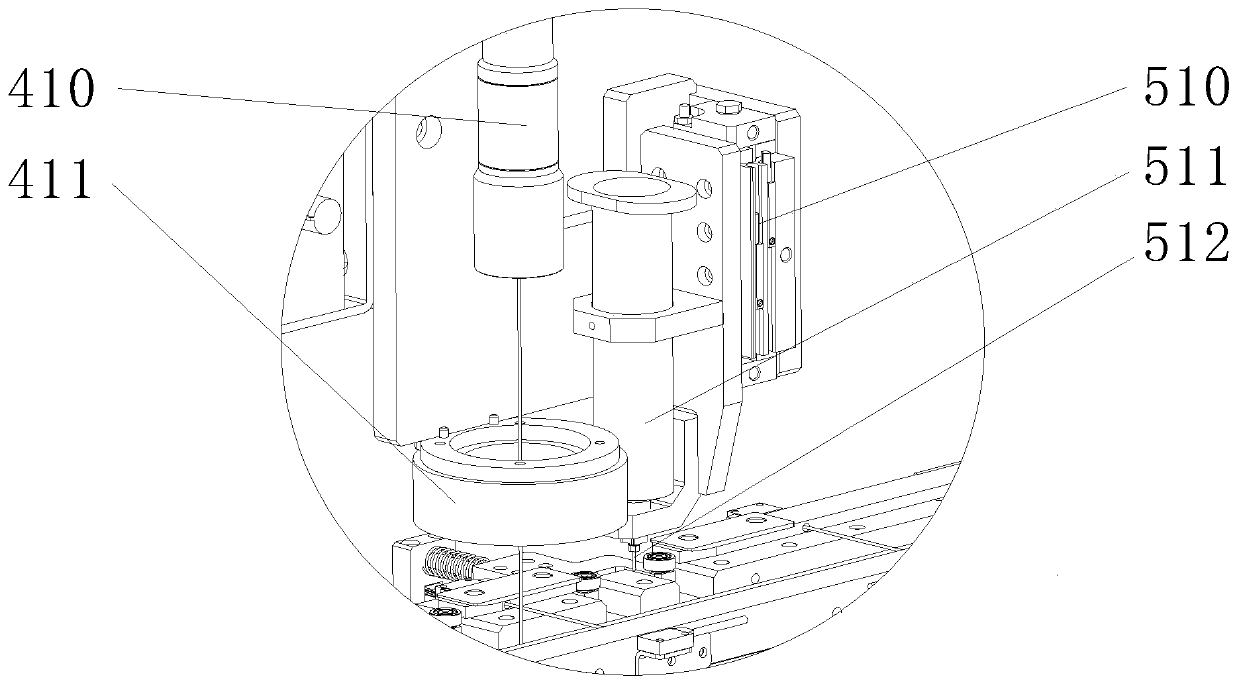

[0032] refer to Figure 1 ~ Figure 2 As shown, the present invention discloses an inductive AOI dispensing machine, including a base 1 and a bracket arranged on it, and a positioning and conveying mechanism 2, a sorting mechanism 3, an AOI mechanism 4 and a glue dispensing mechanism 5 arranged on the bracket .

[0033] refer to Figure 4 ~ Figure 7 As shown, the above-mentioned positioning and conveying mechanism 2 includes a sliding unit, a positioning unit, a pre-transporting unit and a conveying unit arranged on the support.

[0034] The above-mentioned sliding unit includes a conveying track 210 , a limiting protrusion 211 , an interval belt 212 and a position sensor 213 . Two conveying rails 210 are arranged side by side and parallel on the support for conveying the material clip containing the inductor. There is an interval belt 212 between the two conveying tracks 210 . The width of the interval strip 212 is smaller than the width of the material clip, and is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com