Profile forming mold of single-layer door frame

A technology for forming molds and door frames, applied to household appliances, other household appliances, household components, etc., can solve the problems of defective products, inadequate material replenishment, uneven surface of profiles, etc., achieving good flatness, easy disassembly, maintenance and replacement. , good effect of profile forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

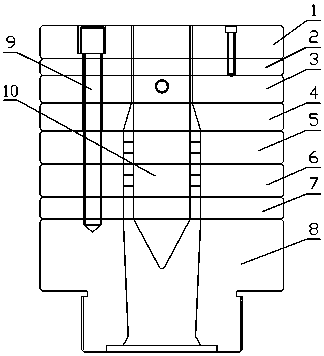

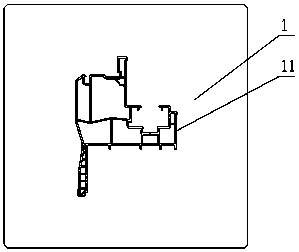

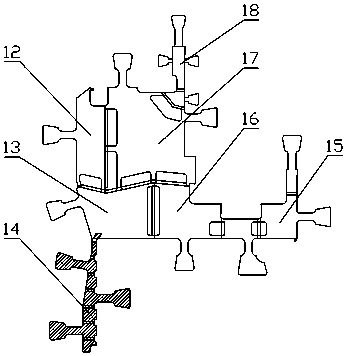

[0015] The present invention is a single-layer door frame profile forming mold, which is connected with the die a1, the die b2, the die c3, the manifold 4, the support plate a5, the support plate b6, the transition plate 7, and the die through the screw 9 from front to back. body 8 and mandrel 10, the mandrel is composed of a large mandrel and a small mandrel, the tail of the big mandrel is embedded in the support plate a and the support plate b at the same time, the front end of the large mandrel is in contact with the outside of the die a The end faces are even, and the front end of the big mandrel is cut into five independent big mandrel a12, big mandrel b17, big mandrel c13, big mandrel d16 and big mandrel e15, the small mandrel Rods include small core rod A14 and small core rod B18, wherein the upper end of small core rod A is embedded in the lower left corner of large core rod c, the lower end of small core rod B is embedded in the upper right corner of large core rod b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com