Novel automatic material even-up and discharging bin system

A silo and automatic technology, which is applied in the field of new automatic silo systems, can solve the problem that the corners of the silo cannot be full, and achieve the effect of avoiding bridging and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

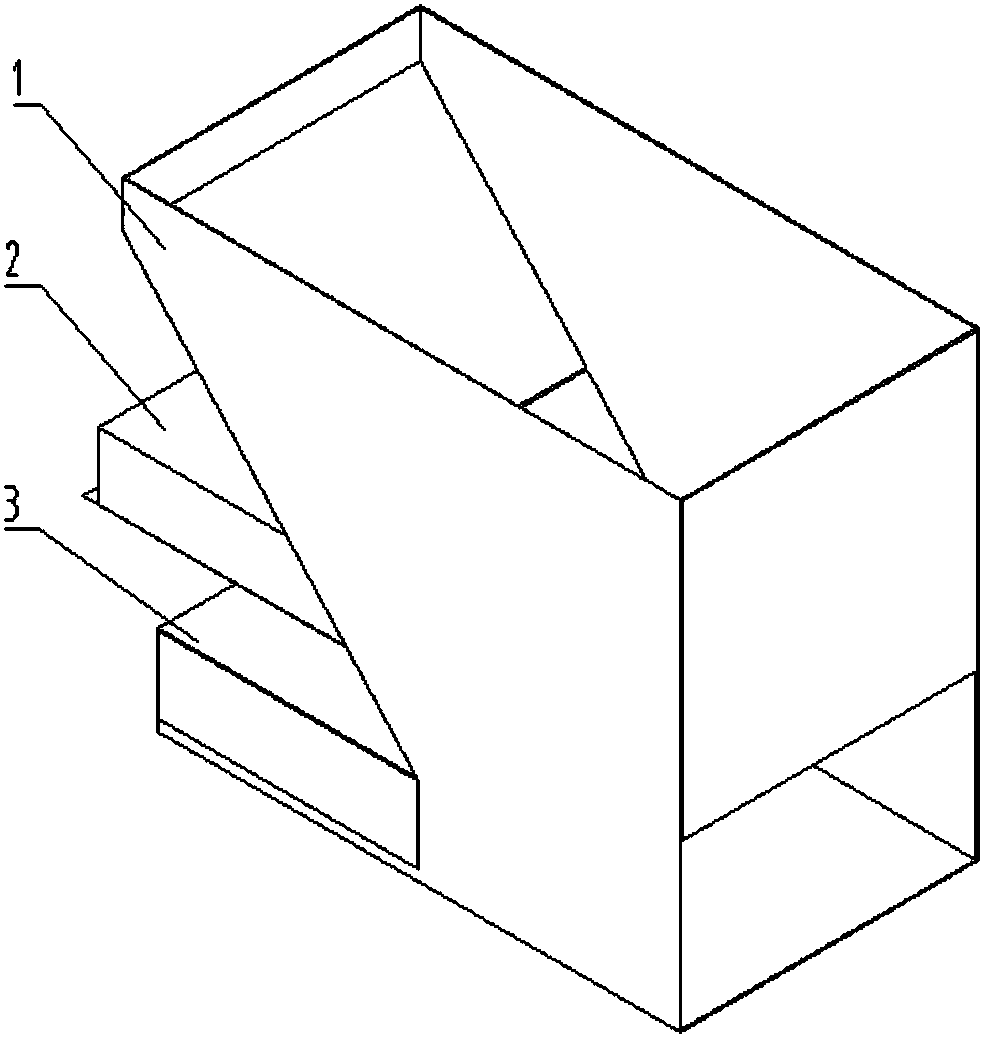

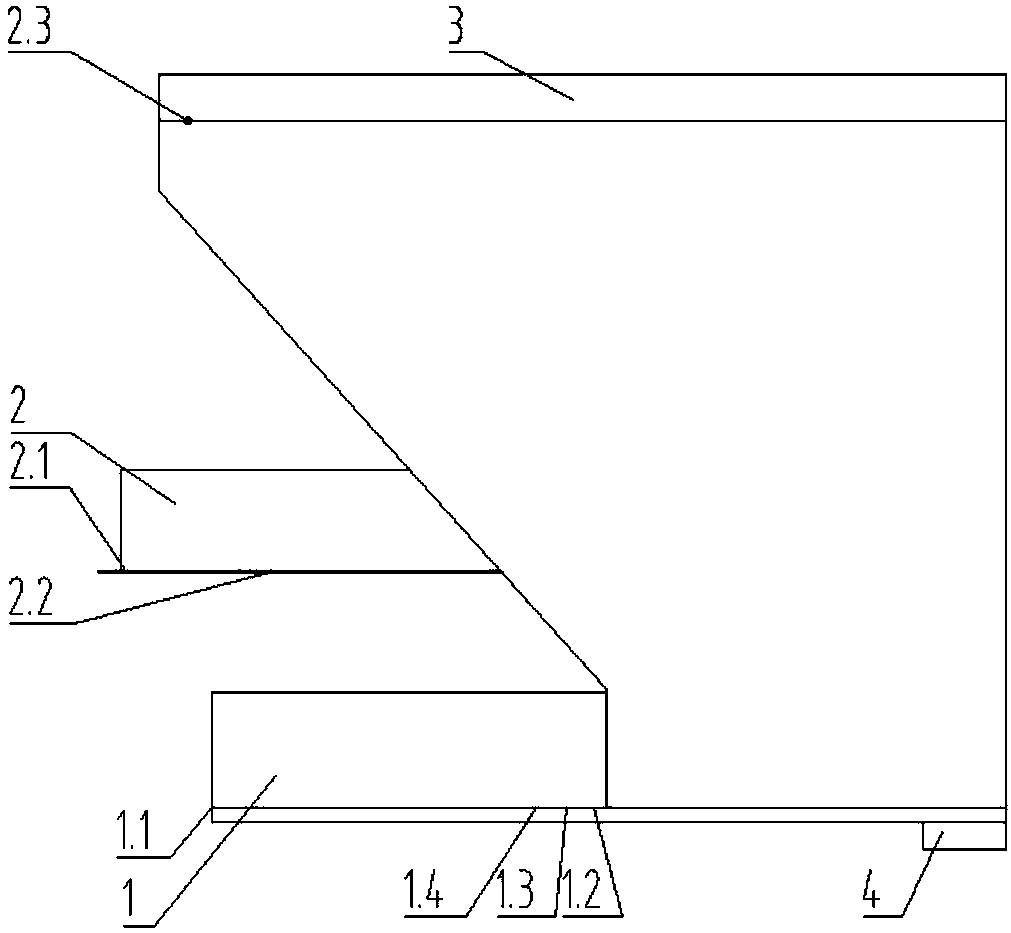

[0016] Attached below figure 1 and figure 2 The present invention is further described in detail

[0017] Such as figure 1 as shown, figure 1 It is a schematic diagram of the overall structure of the present invention. Including 1-bin structure; 2-leveling mechanism; 3-discharging mechanism. Such as figure 2 as shown, figure 2 It is a schematic diagram of electrical components of the present invention. Including 1-discharge mechanism; 1.1-sensor 1; 1.2-sensor 2; 1.3-sensor 3; 1.4-sensor 4; 2-leveling mechanism; 2.1-sensor 1; 2.2-sensor 2; Detection sensor; 3-dust and deodorization system; 4-leachate collection system.

[0018] When the back-end processing equipment is ready, send a signal to the silo system. After the silo system receives the signal, the discharge mechanism enters the working state. During the working process, the specific actions are controlled by various sensors and electrical control systems.

[0019] When the discharge port sensor detects a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com