Hot-blast stove lifting device

A technology of lifting device and hot blast stove, which is applied in the direction of fluid heater, lighting and heating equipment, etc. It can solve the problems of inconvenient installation of lifting mechanism, long time required for carpet, and inability to circulate the loading frame, so as to expand the scope of application and structure Compactness, the effect of shortening a single heating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

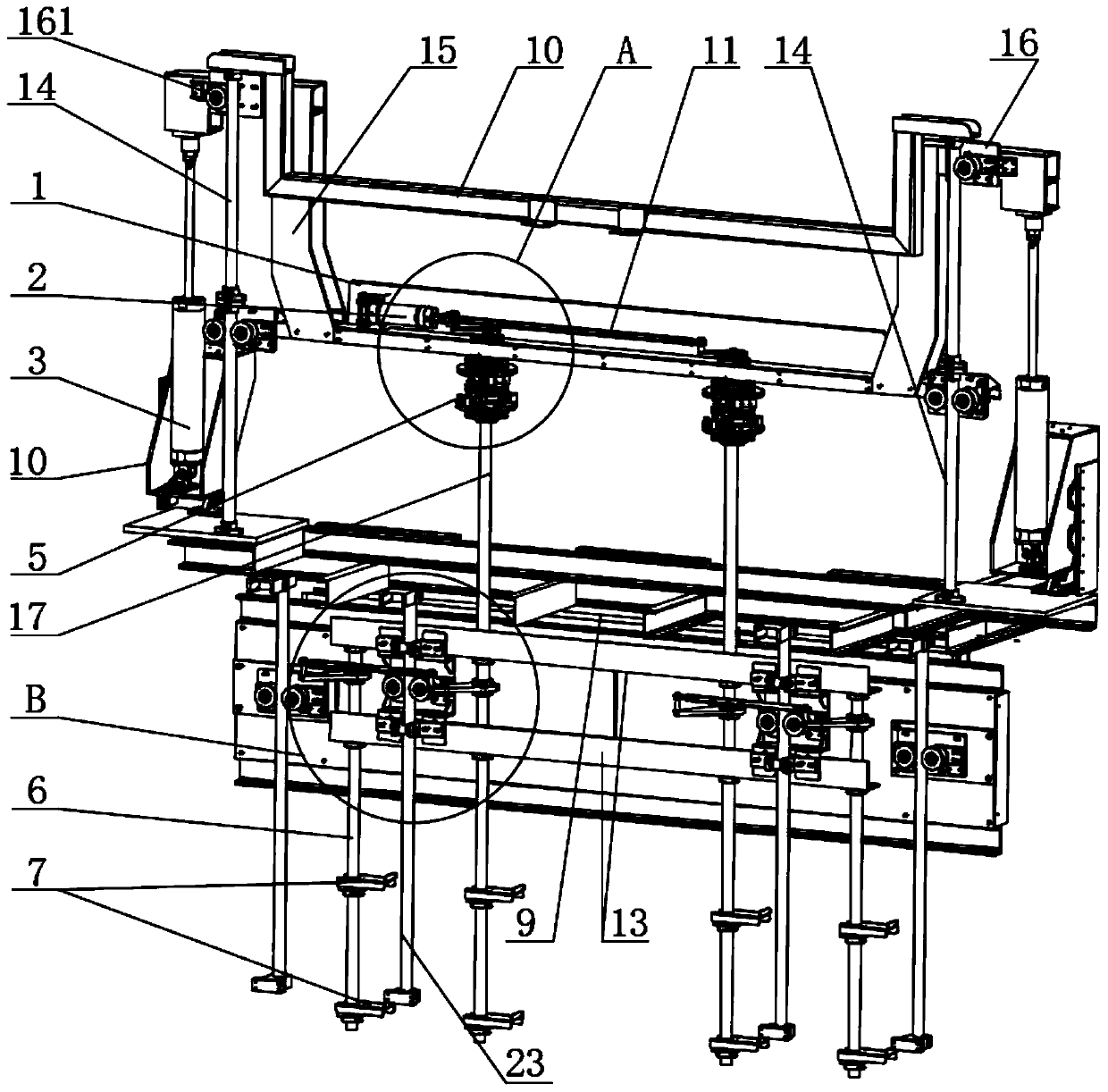

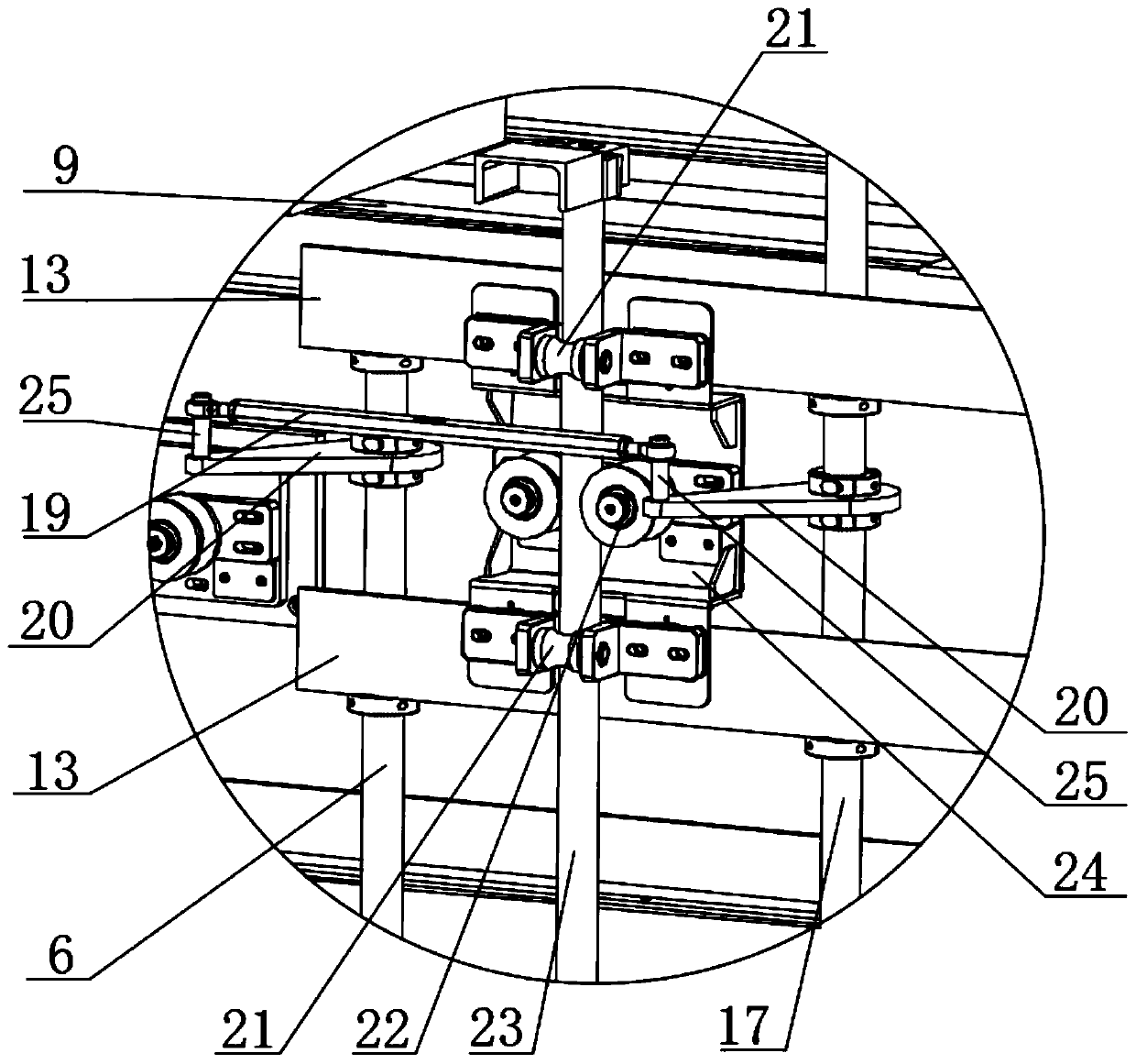

[0029] like figure 1 As shown, the hot blast stove lifting device of the present embodiment includes a support 15, and the support 15 forms a U-shaped structure. On both sides of the U-shaped structure, a side plate 1 is installed on the upper surface of the middle part, and a cylinder 2 is installed along the surface of the side plate 1. A connecting rod 11 is connected to the piston rod, and two couplings are installed at intervals on the connecting rod 11. 5. Each coupling 5 is connected to a driving shaft 17, and each driving shaft 17 is connected to a driven shaft 6 through a transmission mechanism. The driving shaft 17 and the driven shaft 6 are installed with claws at intervals along the axial direction. Disk 7, driving shaft 17 and driven shaft 6 are arranged in parallel.

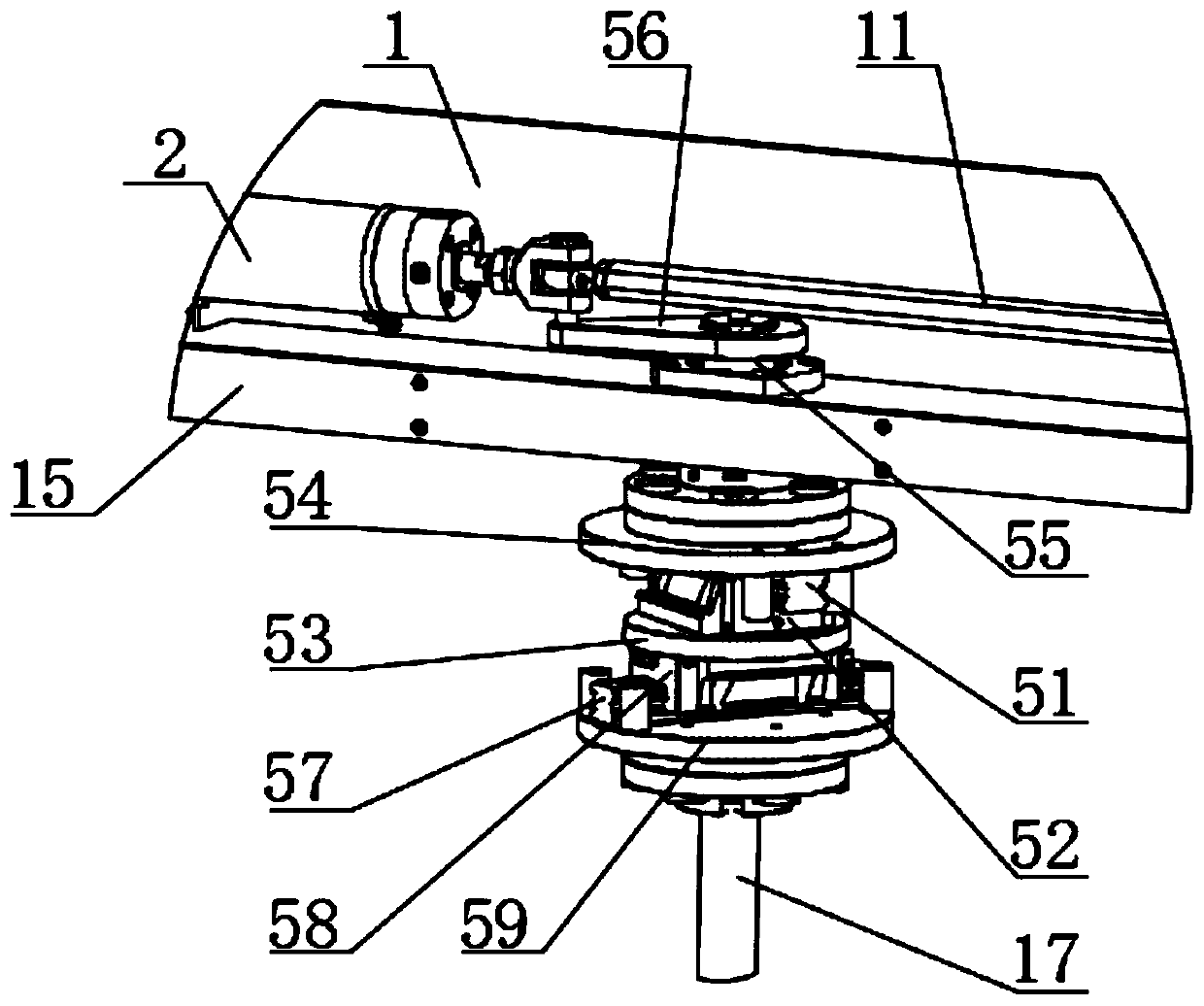

[0030] like figure 2 As shown, the installation struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com