Automatic clothing manufacturing method based on garment style chart

A style map and clothing technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of strong dependence on the experience of modelers, cumbersome garment making process, and high cost, so as to improve competitive advantages, save manpower and Time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be further elaborated below in conjunction with the accompanying drawings.

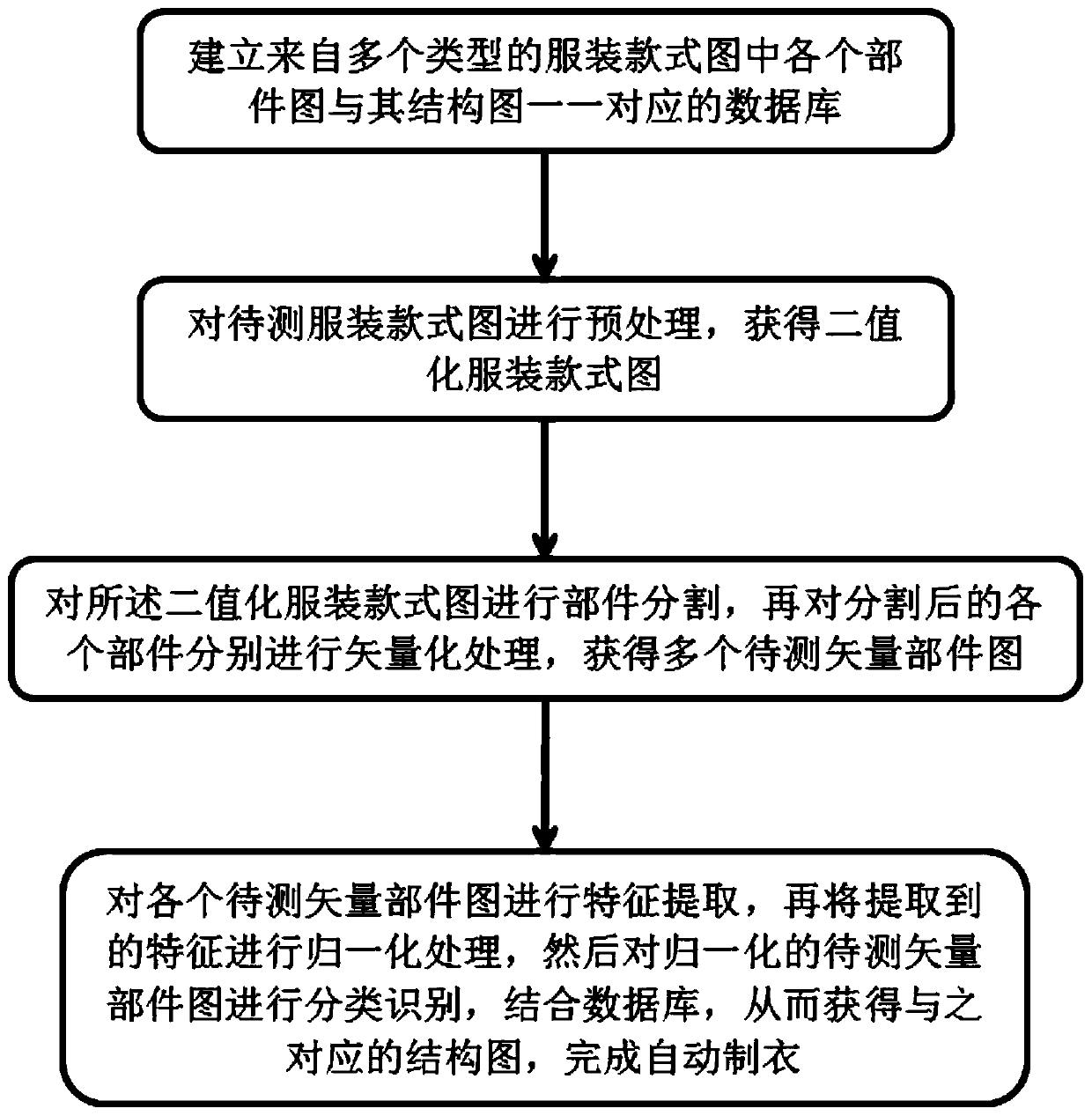

[0047] attached figure 1 For the flow chart of the present invention, the present invention provides a kind of automatic garment-making method based on clothing style chart, comprises the following steps:

[0048] Step 1. Establish various component diagrams and their structures in clothing style diagrams from multiple types Figure 1 A corresponding database.

[0049] These style diagrams and structure diagram sample databases come from two parts: one part is the prepared clothing style diagram and model structure diagram provided by Shanghai PGM Company. There are not many samples, so this part of the samples is mainly used for clothing part segmentation and vectorization; the other part is the clothing part map made by the inventor, which is mainly used for feature extraction and classification recognition of the part style map of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com