Hybrid synchronous reluctance motor with axially interleaved self-cooled rotor

A synchronous reluctance motor, interleaved technology, applied in synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. The problems of high temperature of rotor core and ferrite permanent magnet poles and low utilization rate of cooling gas in the motor can increase the surface heat dissipation coefficient, enhance the ability to start under heavy load, and reduce the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

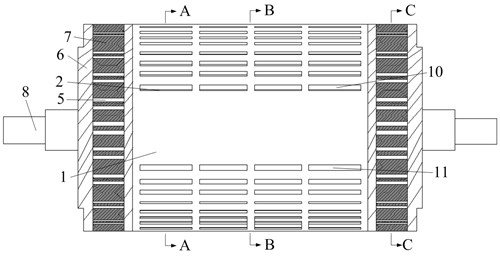

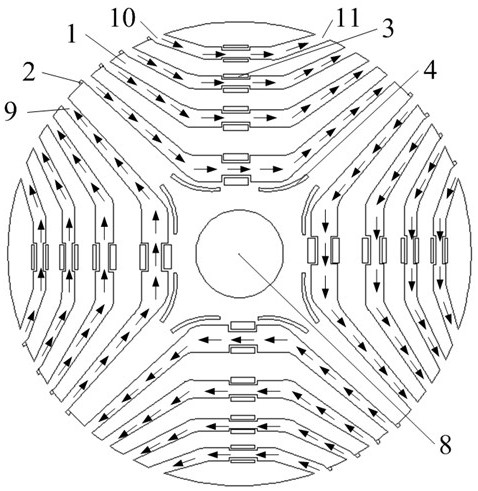

[0030] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment. The hybrid synchronous reluctance motor with an axially staggered self-cooling rotor described in this embodiment includes a rotor laminated core 1, a rotor wind-inducing plate 2, a ferrite permanent magnet pole 3, and a "bow-shaped "Magnetic attraction hole 4, "double convex" copper-nickel alloy starting cage bar 5, rotor end ring 6, rotor integral core 7, rotor shaft 8 and rotor magnetic barrier 9.

[0031] "Double convex" copper-nickel alloy starting cage bar 5 is composed of double slender copper-nickel alloy starting cage bar 5-1 and rectangular copper-nickel alloy starting cage bar 5-2, and the rotor end ring 6 is composed of the rotor left end ring 6- 1. Rotor left-biased middle end ring 6-2, rotor right-biased middle end ring 6-3 and rotor right end ring 6-4; rotor integral core 7 consists of rotor left integral iron core 7-1 and roto...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination Image 6 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that the air inlet 10 of the rotor magnetic barrier 9 is opened as one along the axial direction at its corresponding circumferential position, and the air outlet of the rotor magnetic barrier 9 11 is provided as one in the axial direction at its corresponding circumferential position, which can increase the flow rate of cooling gas entering the rotor magnetic barrier 9, and further reduce the gap between the rotor laminated core 1 and the ferrite permanent magnet pole 3. temperature.

[0040] Other components and connections are the same as those in Embodiment 1.

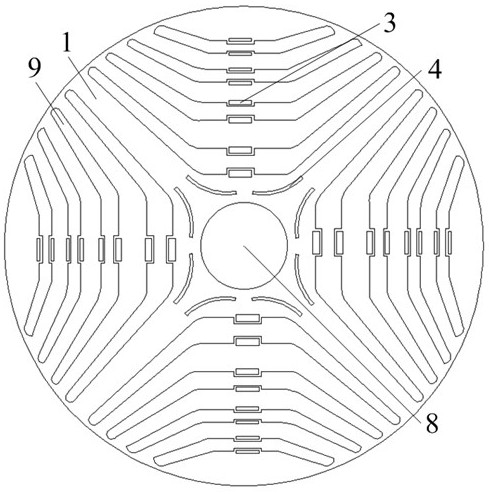

specific Embodiment approach 3

[0041] Specific implementation mode three: combination Figure 7 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that a magnetic attraction groove 12 is provided on the outer diameter of the rotor laminated core 1, which further enhances the overload capacity of the motor and improves the power density and operating efficiency of the motor. .

[0042] Other components and connections are the same as those in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap