Ring traveler

A traveler and coating technology, which is applied in coatings, textiles, papermaking, lubricating compositions, etc., to achieve the effects of improving anti-friction characteristics, improving performance, and improving wear characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

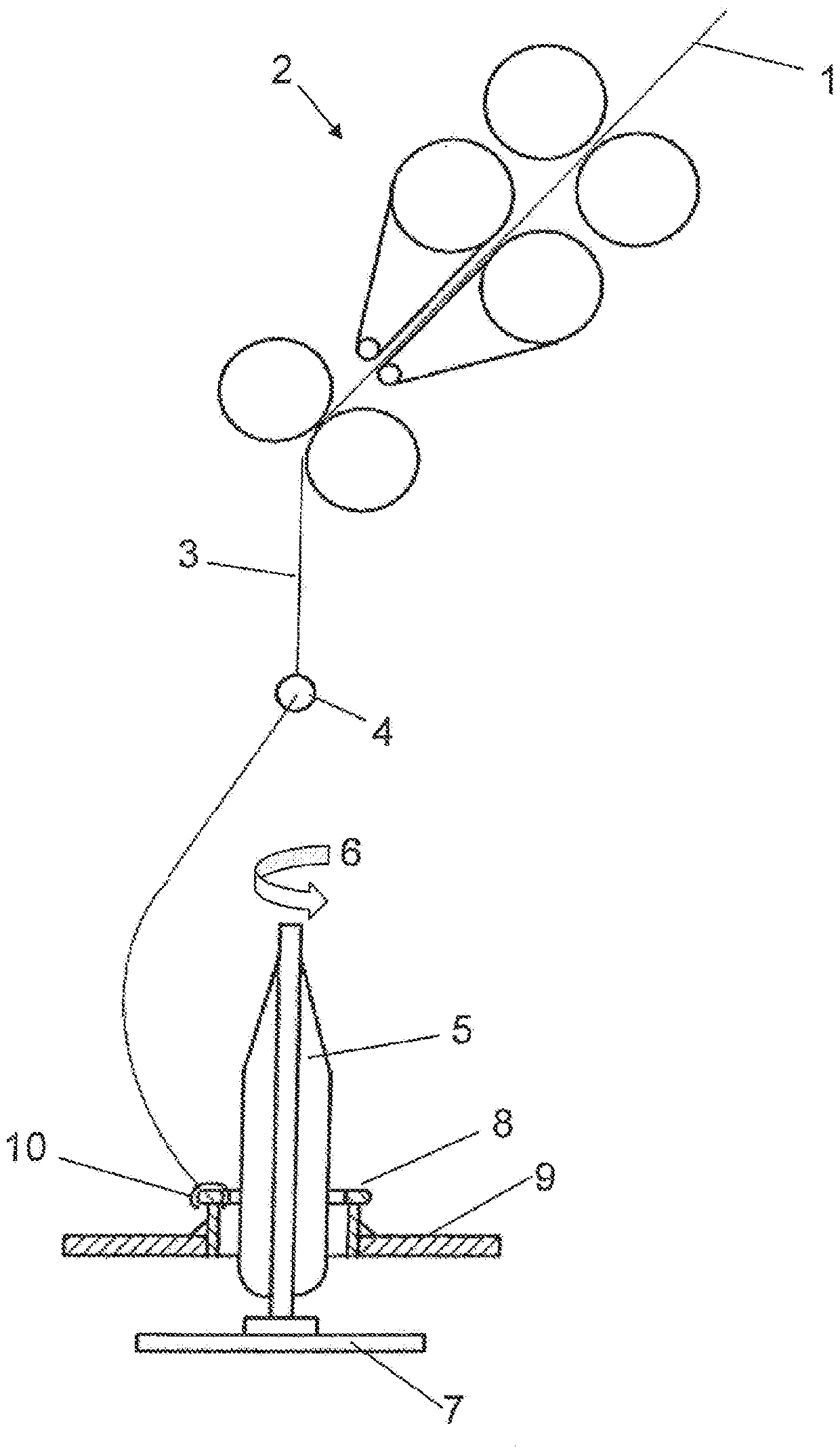

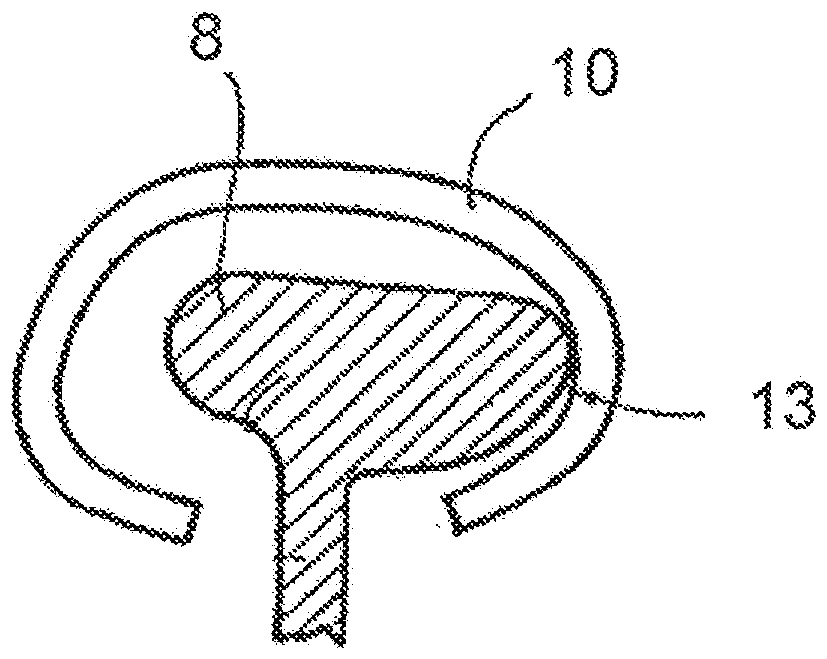

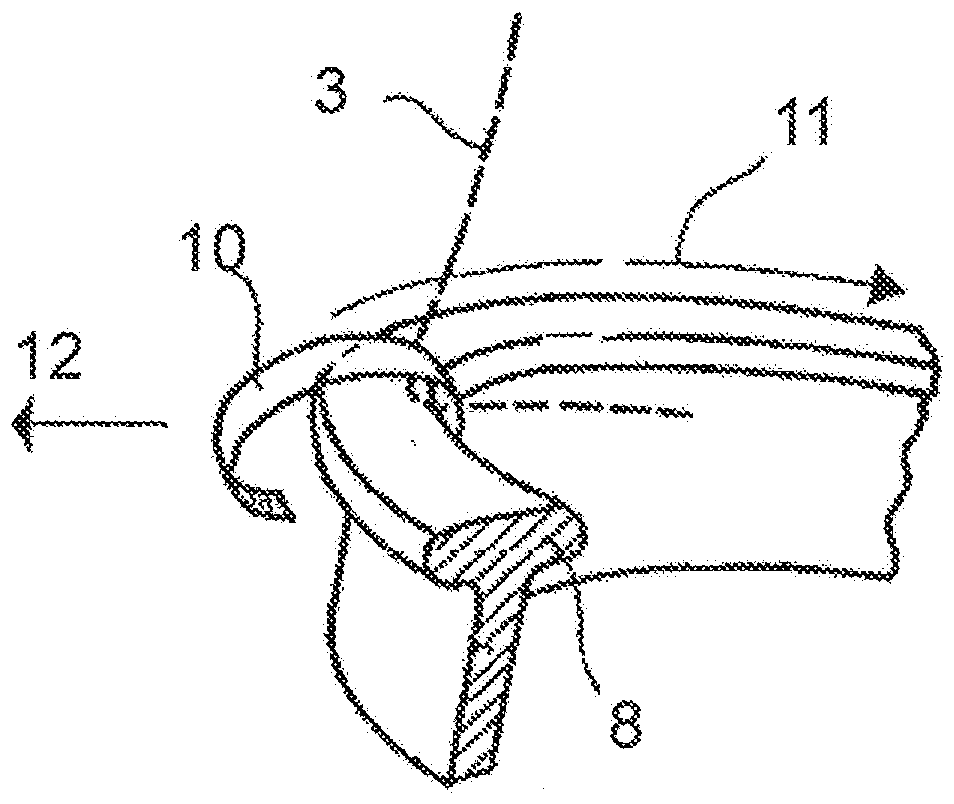

[0018] figure 1 A schematic diagram of the spinning positions of a ring spinning machine is shown, so that current ring spinning machines have up to 2000 such spinning positions. The fiber bundle (the so-called sliver 1) is fed to the take-off unit 2 in the ring spinning machine. The sliver 1 is drawn by a drawing unit 2 to form a thread 3 . The pulling unit 2 shown here is a so-called belt pulling unit, which is usually used for cotton. Depending on the application, various designs for the pulling unit 2 are known from the prior art. The wire 3 is guided to the traveler 10 via the thread guide 4 downstream of the pulling unit 2 . After passing through the traveler 10 , the thread 3 is wound onto the yarn bobbin 5 . The yarn bobbin 5 is set in rotation 6 by a drive 7 . Due to this rotation 6, the traveler 10 is entrained by the wire 3, which causes twist to be imparted to the wire 3, forming a yarn. Due to the fact that the traveler 10 is held on the ring 8 , the travele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com