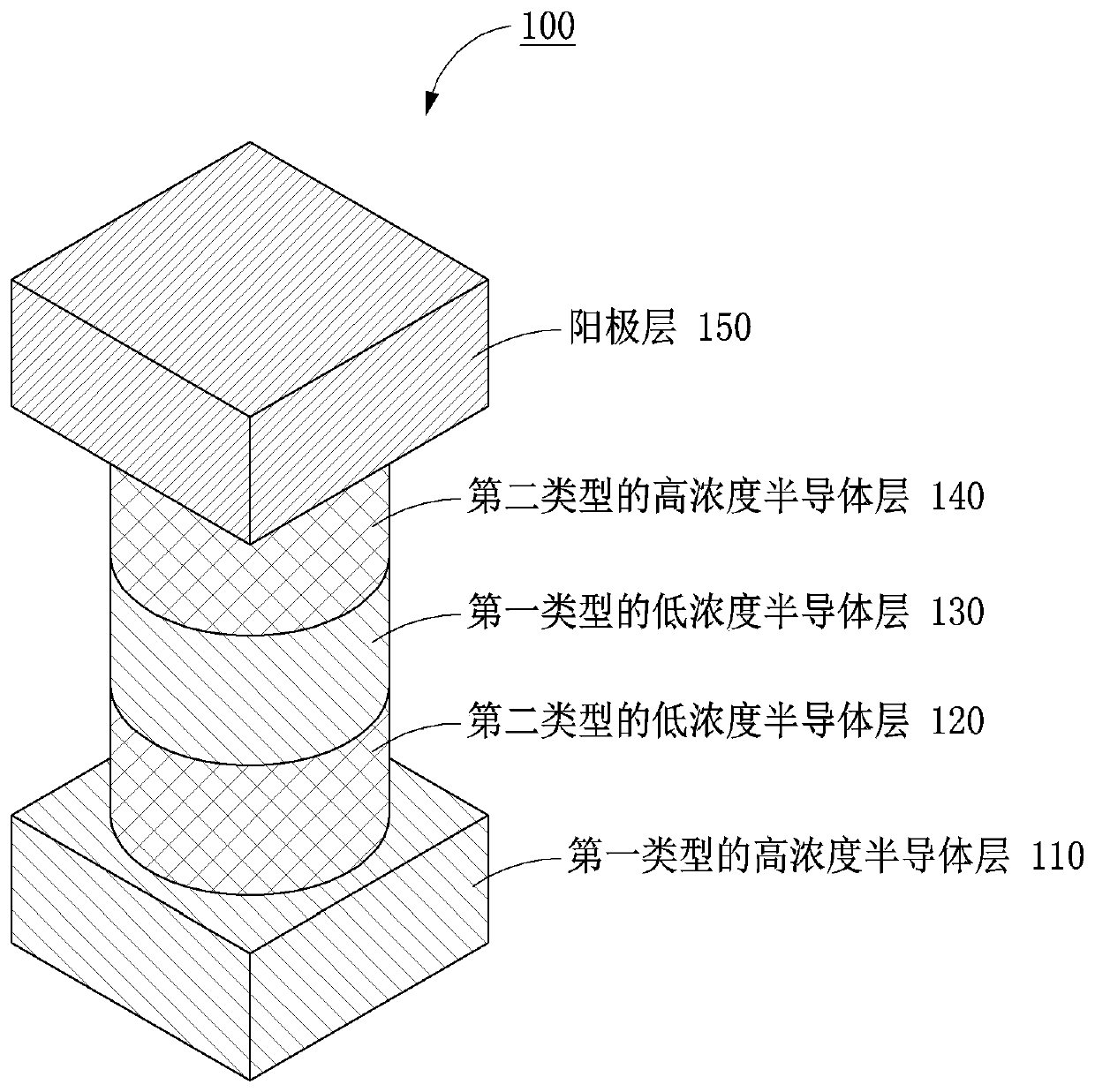

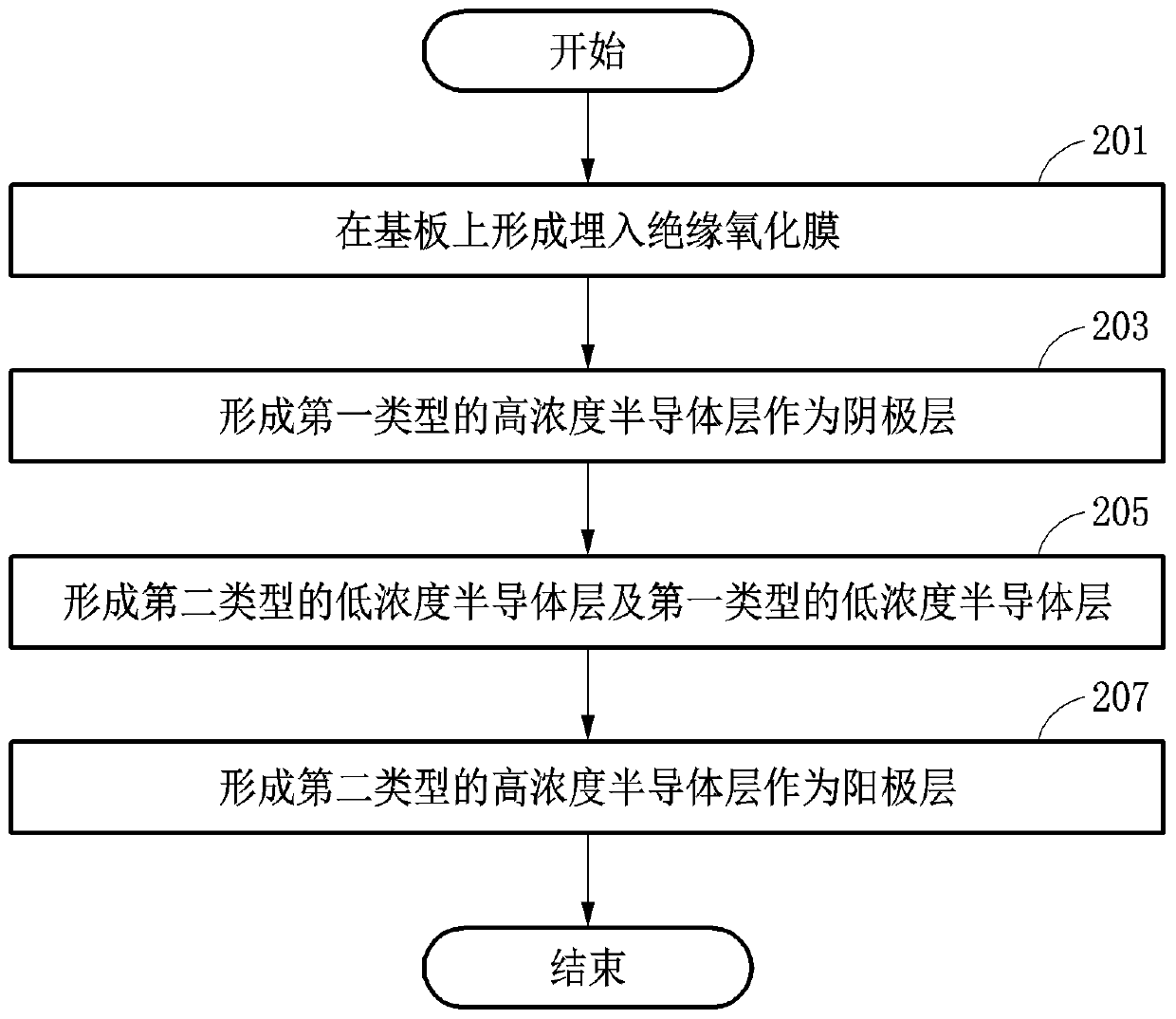

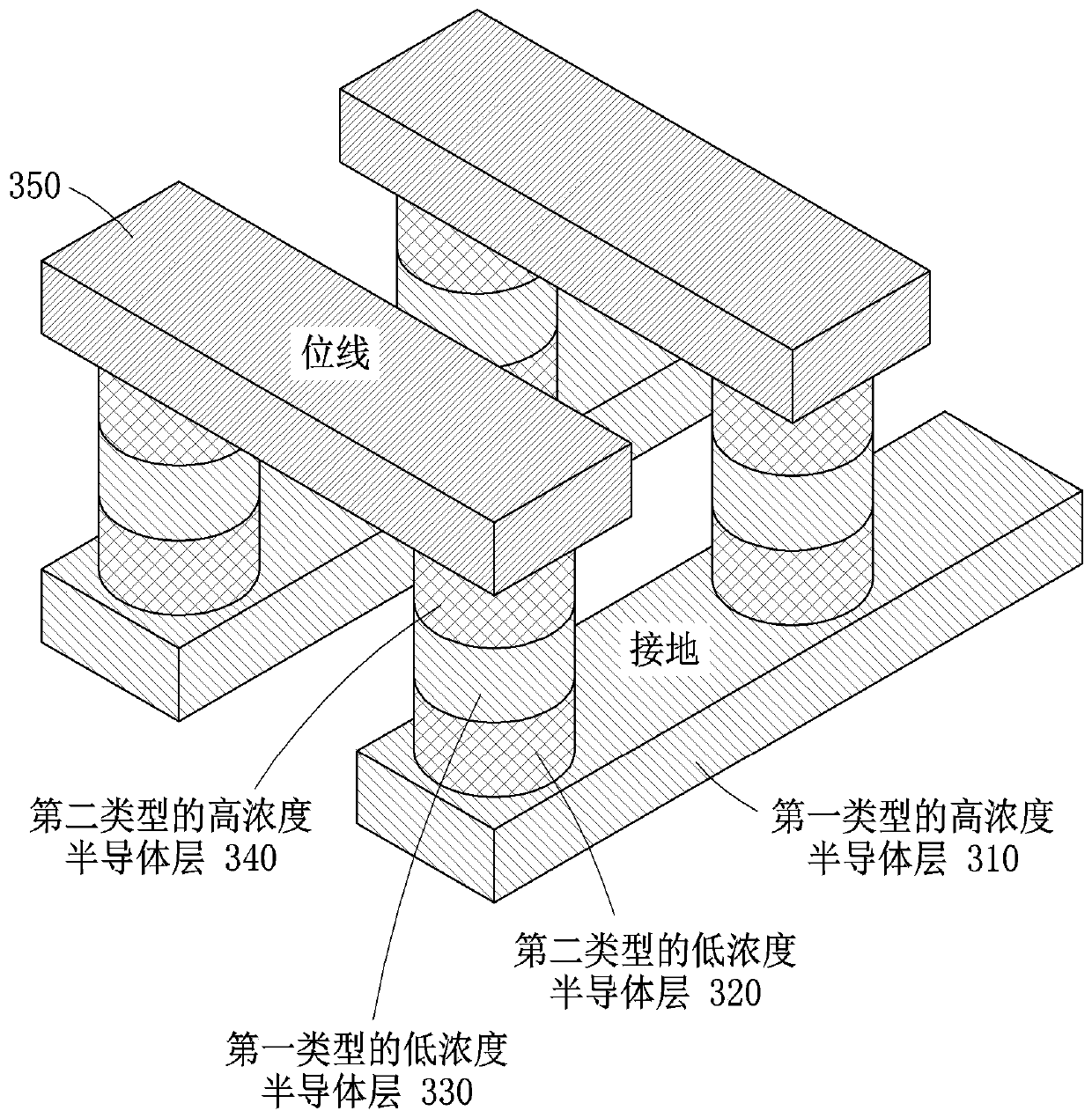

Two-terminal vertical type 1t-dram and manufacturing method therefor

一种动态随机存取、制造方法的技术,应用在半导体器件、电固体器件、二极管等方向,能够解决面积广、阻塞等问题,达到克服物理限制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, various embodiments of the present specification will be described with reference to the accompanying drawings.

[0044] It should be understood that the embodiments and the terms used are not intended to limit the technology described in this description to specific implementations, but include various modifications, equivalent technical solutions, and / or replacement technical solutions of the corresponding embodiments.

[0045] Hereinafter, in the description of various embodiments, when it is judged that the specific description of related known functions or structures makes the gist of the present invention unclear, the detailed description thereof will be omitted.

[0046] Also, terms described later are terms defined in consideration of functions in various embodiments, and may be changed according to user's, operator's intention, or custom. Therefore, its definition should be based on what is found throughout the specification.

[0047] With regard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com