Electrochemical machining device based on magnetic deformation electrode and electrochemical machining method of electrochemical machining device

An electrochemical machining and machining method technology, applied in electrochemical machining equipment, electric machining equipment, electrode manufacturing, etc., can solve the problem of lack of good machining methods, and achieve the effects of wide application fields, promotion of chip removal, and convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

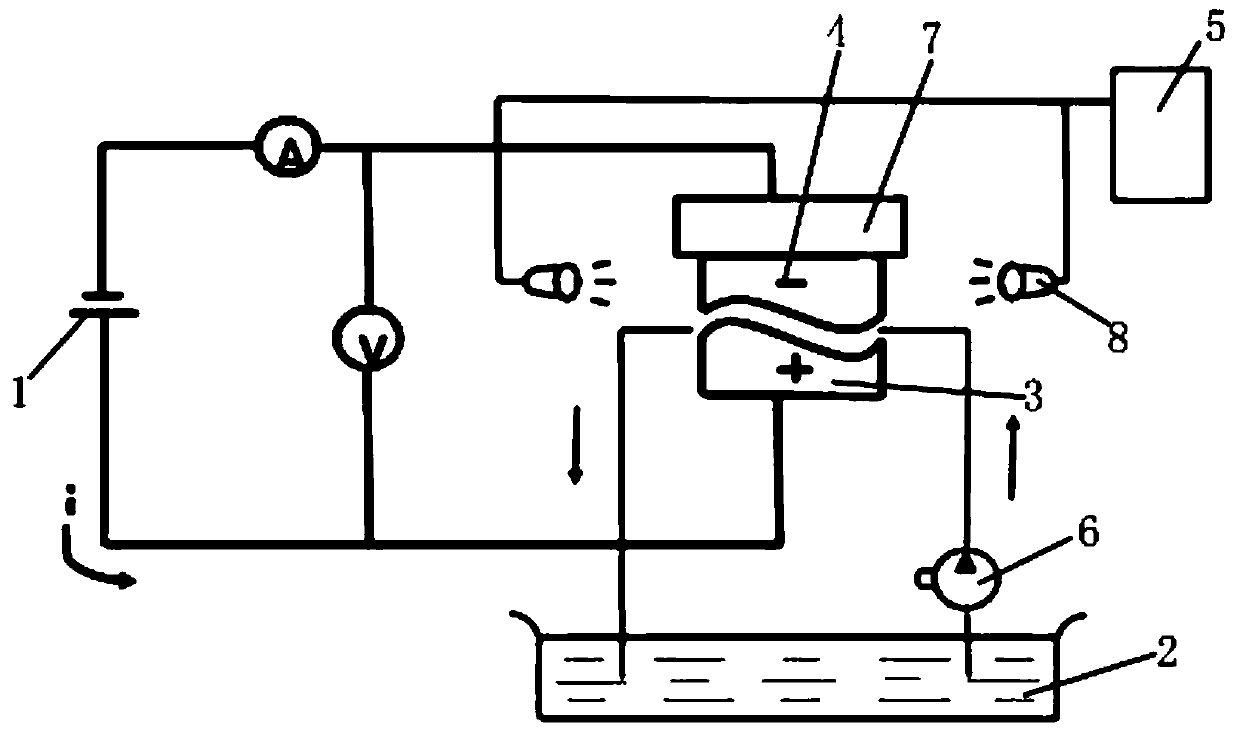

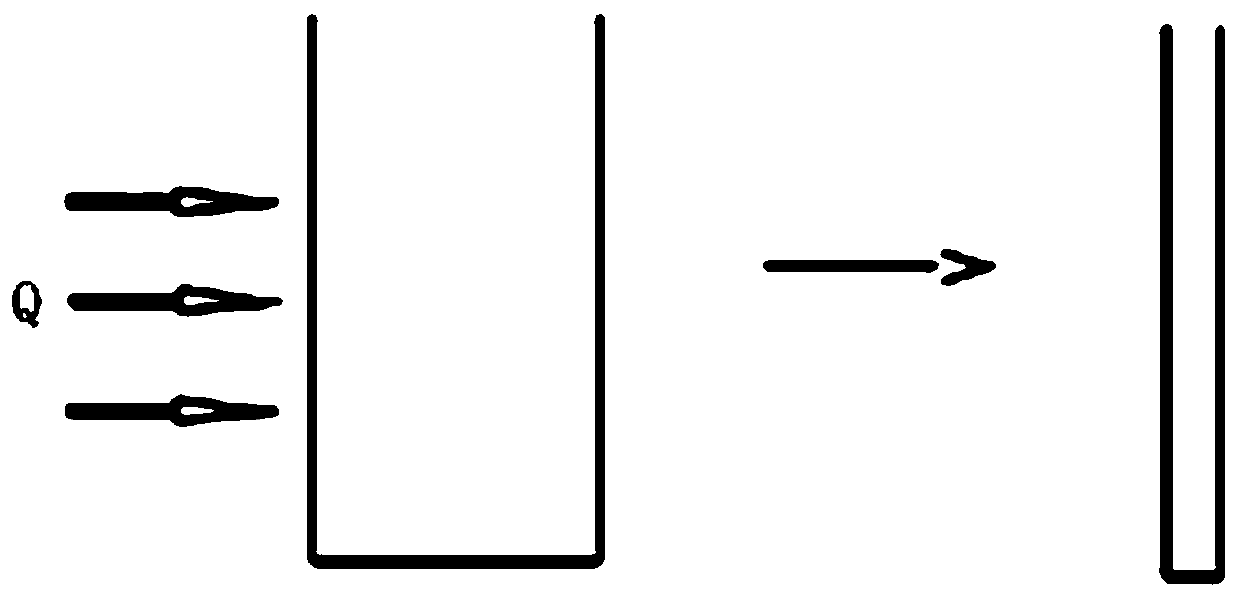

[0062] Such as figure 2 , 3 As shown in and 5, changing the electrode size or shape to a preset electrode size or shape specifically includes the following steps:

[0063] S1. The magnetic source 5 generates a magnetic field, and the size or shape of the electrode changes to a preset size or shape.

[0064] Here, if the magnetic field strength cannot change the size or shape of the electrode to the required size or shape, parameters such as magnetic field strength and time can be changed through the magnetic field regulator 8, so that the size or shape of the electrode can be changed to a preset size or shape.

[0065] S2. The power supply 1 supplies power to form an electric field between the electrode 4 and the workpiece 3 .

[0066] S3, the electrolyte solution and the workpiece 3 undergo an electrochemical reaction under the action of an electric field until the desired workpiece is obtained.

[0067] It should be noted that, to obtain the processing of the special-sha...

Embodiment approach 2

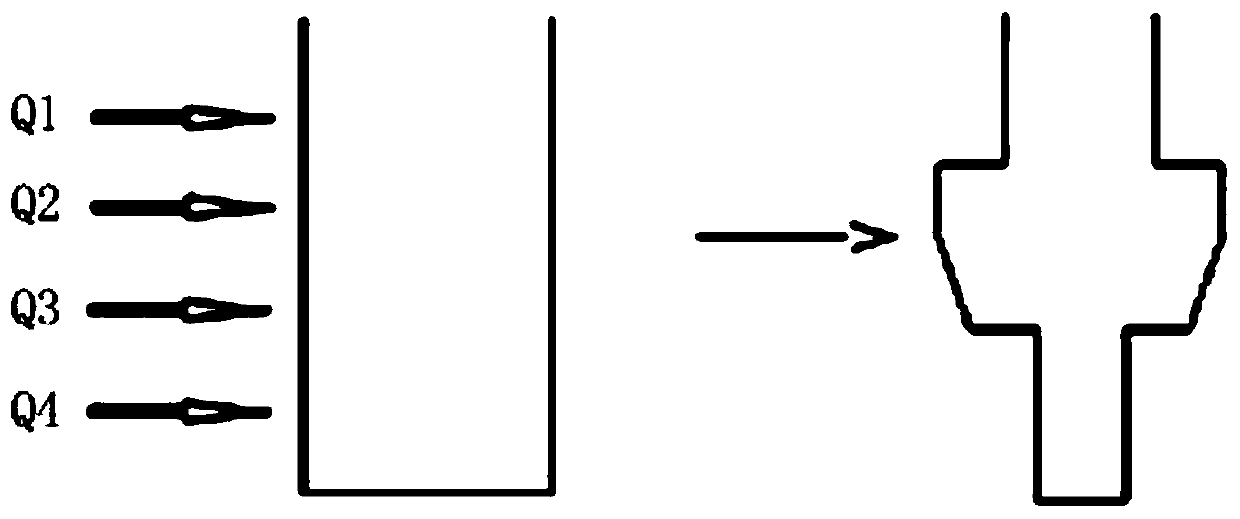

[0069] Such as Figure 4 and 6 As shown, during the electrochemical reaction process, the shape of the electrode is changed to obtain a workpiece with a curved flow channel, which specifically includes the following steps:

[0070] S1, the magnetic source 5 generates a magnetic field, and the size of the electrode is changed to the required size.

[0071] Here, if the magnetic field strength cannot change the electrode size to the required size, parameters such as magnetic field strength and time can be changed through the magnetic field regulator 8, so that the electrode size can be changed to a preset size.

[0072] S2. The power supply 1 supplies power to form an electric field between the electrode and the workpiece.

[0073] S3, the electrolyte solution and the workpiece 3 undergo an electrochemical reaction under the action of an electric field until the workpiece in the first flow channel is obtained.

[0074] S4. Changing the shape of the electrode through the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com