Gypsum container and preparation method thereof

A gypsum and container technology, applied in the field of gypsum containers and their preparation, can solve problems such as inability to meet demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

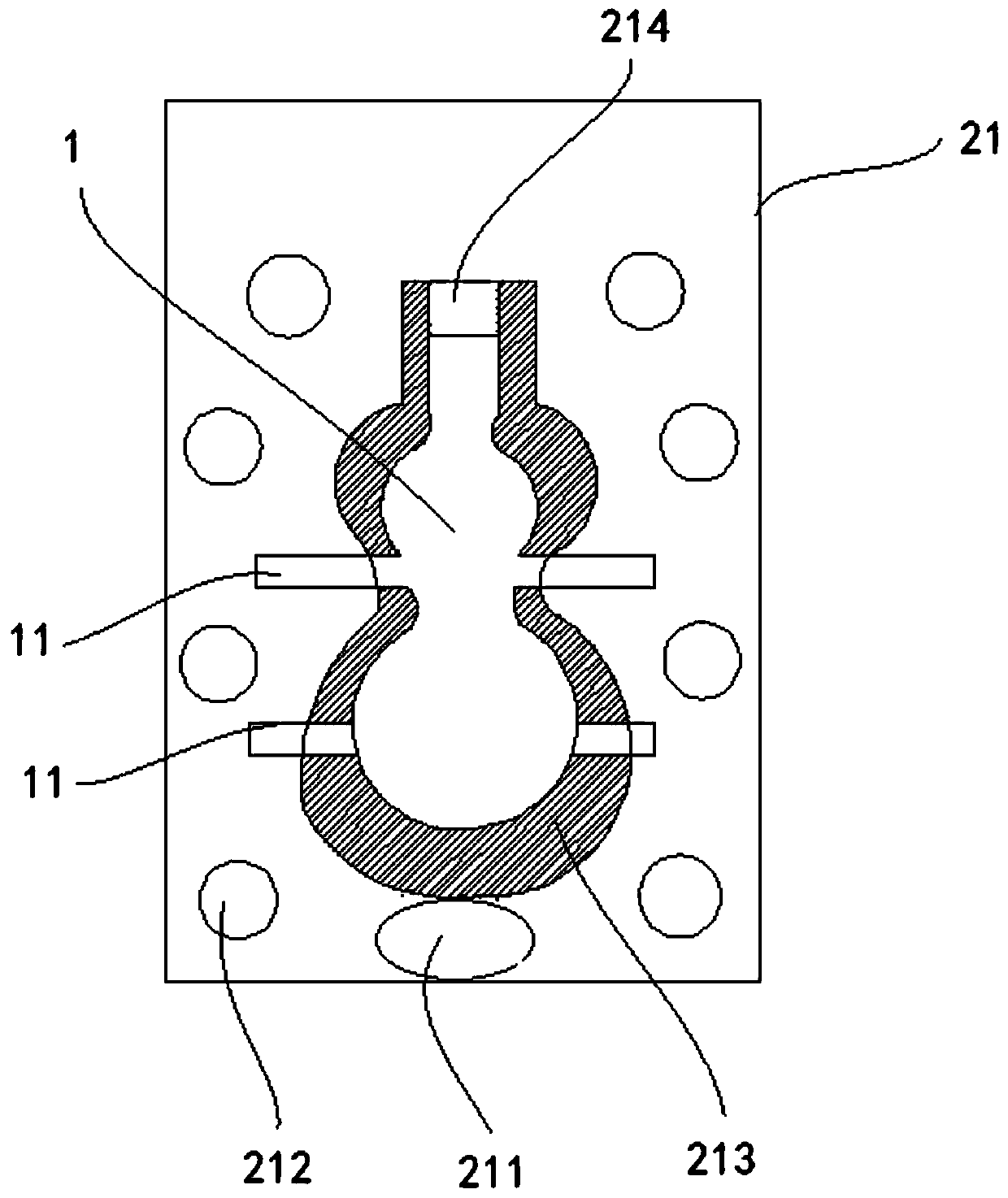

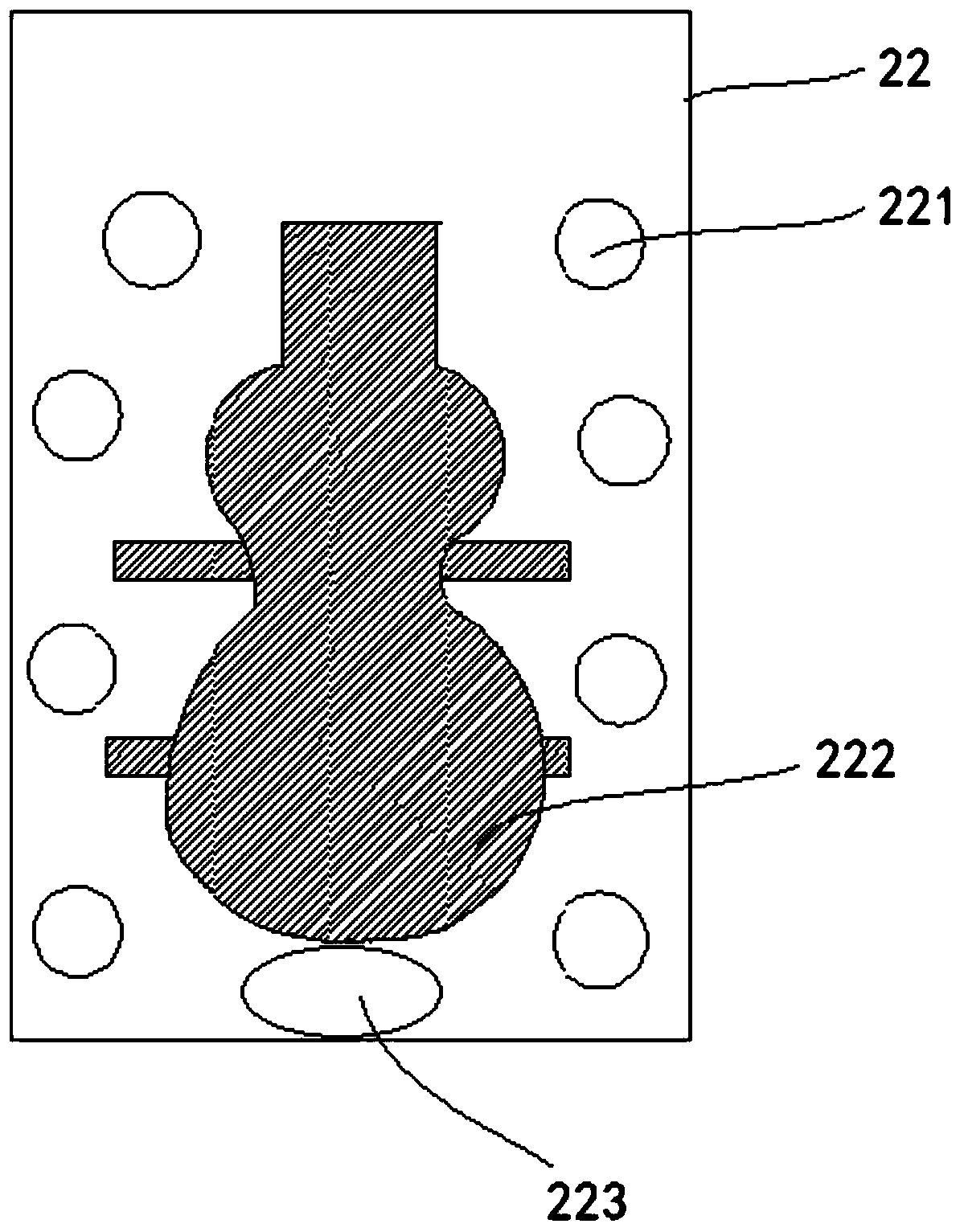

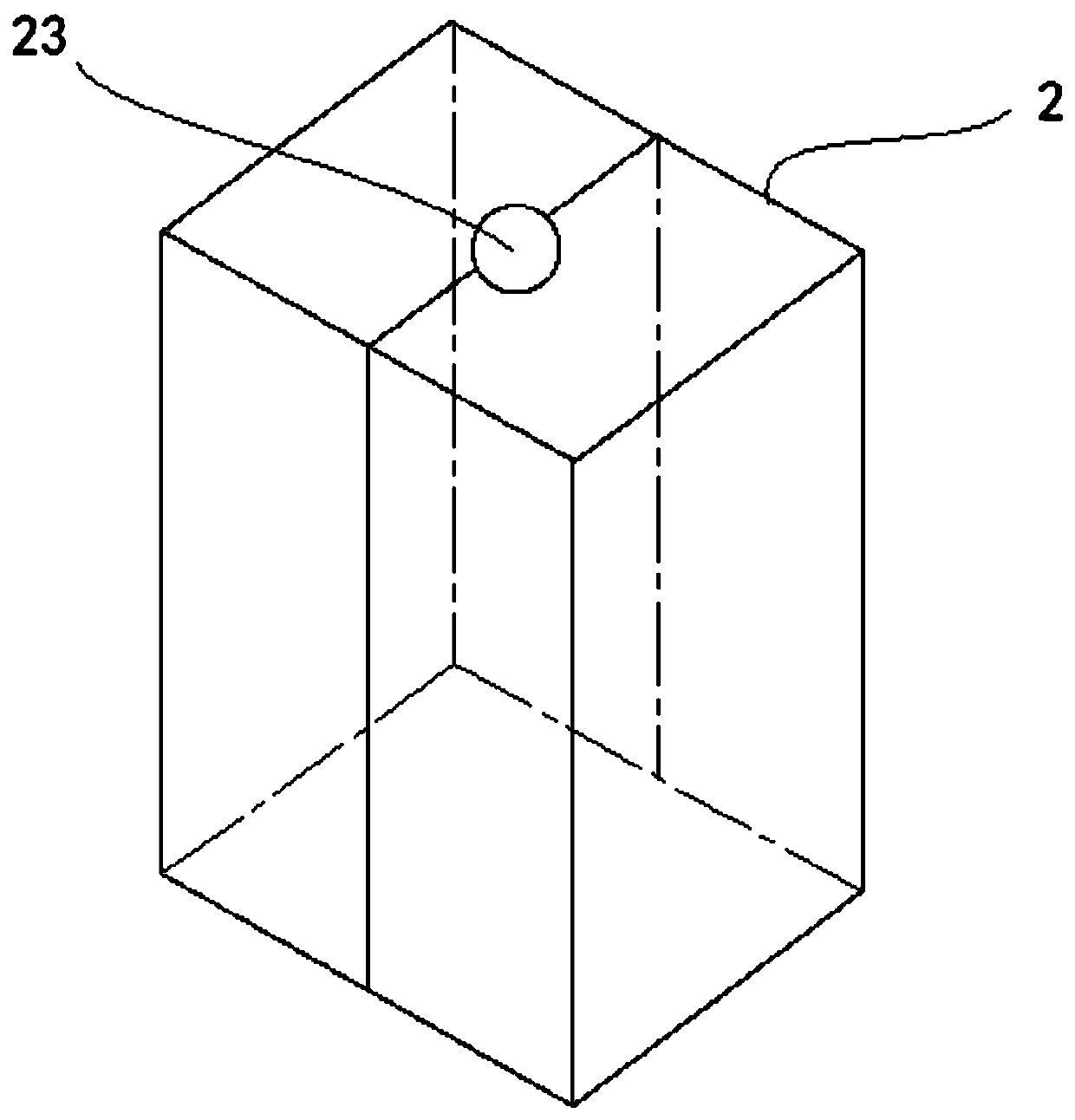

[0022] A gypsum container, the preparation method of which is:

[0023] Step 1, the making of inner container body: as Figure 4 As shown, the inner container body mold 3 is first made, and the inner container body mold 3 includes a detachably connected inner container body mold lower layer 31 and an inner container body mold upper layer 32, and the inner container body mold lower layer 31 includes a The third groove 311, the third concave half hole 312 on the side, the upper layer 32 of the inner container body mold includes the fourth groove 321 on the inside, the fourth concave half hole 322 on the side; The outer edges of the third groove 311 and the fourth groove 321 match; the third concave half hole 312 matches the outer edge of the fourth concave half hole 322 and the corresponding position is set, the third concave half hole The half hole 312 and the fourth concave half hole 322 are combined to form the casting hole 33 of the inner container body.

[0024] Place a p...

Embodiment 2

[0039] This embodiment is the same as embodiment 1 except that the film-forming liquid is different. The film-forming solution in this embodiment includes silica sol, thickener, and stabilizer, and the weight-to-number ratio of the silica sol, thickener, and stabilizer is 1:0.1:0.3. The stabilizer is a barium cadmium stabilizer and / or a barium zinc stabilizer; the thickener includes at least one of raw gypsum, ethoxylated alkyl sulfide wax, and dodecylsulfonate paraffin wax.

Embodiment 3

[0041] This embodiment is the same as embodiment 1 except that the film-forming liquid is different. The film-forming solution in this embodiment includes silica sol, thickener, and stabilizer, and the weight-to-number ratio of the silica sol, thickener, and stabilizer is 1:0.3:0.1. The stabilizer is a barium cadmium stabilizer and / or a barium zinc stabilizer; the thickener includes at least one of raw gypsum, ethoxylated alkyl sulfide wax, and dodecylsulfonate paraffin wax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com