Displaying method of hot-rolled product austenite grains

A technology of austenite grain and display method, which is applied in the field of grain size inspection and can solve the problems of mixed crystals easily appearing in grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0026] Example 1 and Comparative Example 1: The display method of the austenite grains of the hot-rolled material is specifically described as follows.

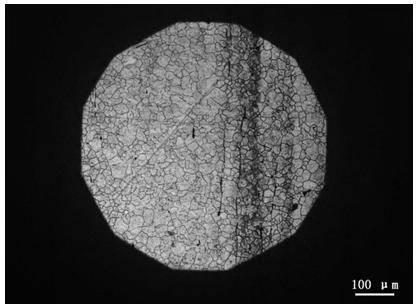

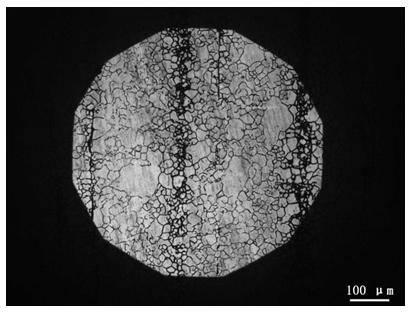

[0027] Two samples were taken from the 18CrNiMo7-6 hot-rolled material, namely sample 1 and sample 2. Sample 1 was loaded into the heating furnace at a furnace temperature of 500 ° C, and the temperature was raised to 930 ° C with the furnace, and the heating time was 65 minutes; sample 2 was loaded into the furnace; sample 1 and sample 2 were kept together for 4 hours; to room temperature. After heat treatment, samples 1 and 2 were cut to 1.0mm, ground and polished, and then corroded with supersaturated picric acid aqueous solution with 1 drop / 100mL of mercaptobenzothiazole added dropwise. The corrosion temperature was 75°C and the corrosion time was After 20s, wipe the sample with absorbent cotton; repeat the corrosion until the grain boundary corrosion is clear. Sample 1 is the sample of this embodiment, and sample 2 is ...

Embodiment 2 and comparative example 2

[0028] Example 2 and Comparative Example 2: The display method of the austenite grains of the hot-rolled material is specifically described as follows.

[0029] Take 2 samples from the 45H hot-rolled material. Sample 1 was loaded into the heating furnace at a furnace temperature of 480 ° C, and the temperature was raised to 960 ° C with the furnace, and the heating time was 70 minutes; After heat treatment, the sample was cut to 1.2 mm, ground and polished, and corroded with a supersaturated picric acid aqueous solution with 2 drops / 100 mL of cetylamine added dropwise. The corrosion temperature was 70 °C and the corrosion time was 25 s. Repeat the corrosion until the grain boundary corrosion is clear. Sample 1 and sample 2 were observed and graded with a metallographic microscope at 100 times magnification. The grain size rating of sample 1 is 7.0, the grain size is uniform, and there is no mixed crystal grain; the grain size rating of sample 2 is 6.5-3, the grain size is un...

Embodiment 3 and comparative example 3

[0030] Example 3 and Comparative Example 3: The display method of the austenite grains of the hot-rolled material is specifically described as follows.

[0031] Take 2 samples from the 22CrMo hot-rolled material. Sample 1 was loaded into the heating furnace at a furnace temperature of 470 ° C, and the temperature was raised to 940 ° C with the furnace, and the heating time was 60 minutes; After the sample is cut to 0.8mm, ground and polished, it is corroded with a supersaturated picric acid aqueous solution with 1 drop / 100mL of benzotriazole added dropwise. The corrosion temperature is 80°C and the corrosion time is 15s. Wipe the sample with absorbent cotton; repeat the corrosion until the grain boundary corrosion is clear. Sample 1 and sample 2 were observed and graded with a metallographic microscope at 100 times magnification. The grain size rating of sample 1 is 7.0, the grain size is uniform, and there is no mixed crystal grain; the grain size rating of sample 2 is 7-3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com