Method for treating steel pipe pile foundation on riprap seabed foundation

A treatment method and technology of steel pipe piles, which are applied in the fields of infrastructure engineering, erection/assembly of bridges, soil protection, etc., can solve the problems of poor economy, high cost of riprap seabed foundation treatment, and long construction period, and achieve increased Work efficiency, reducing the input of large-scale measures, and the effect of reasonable structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

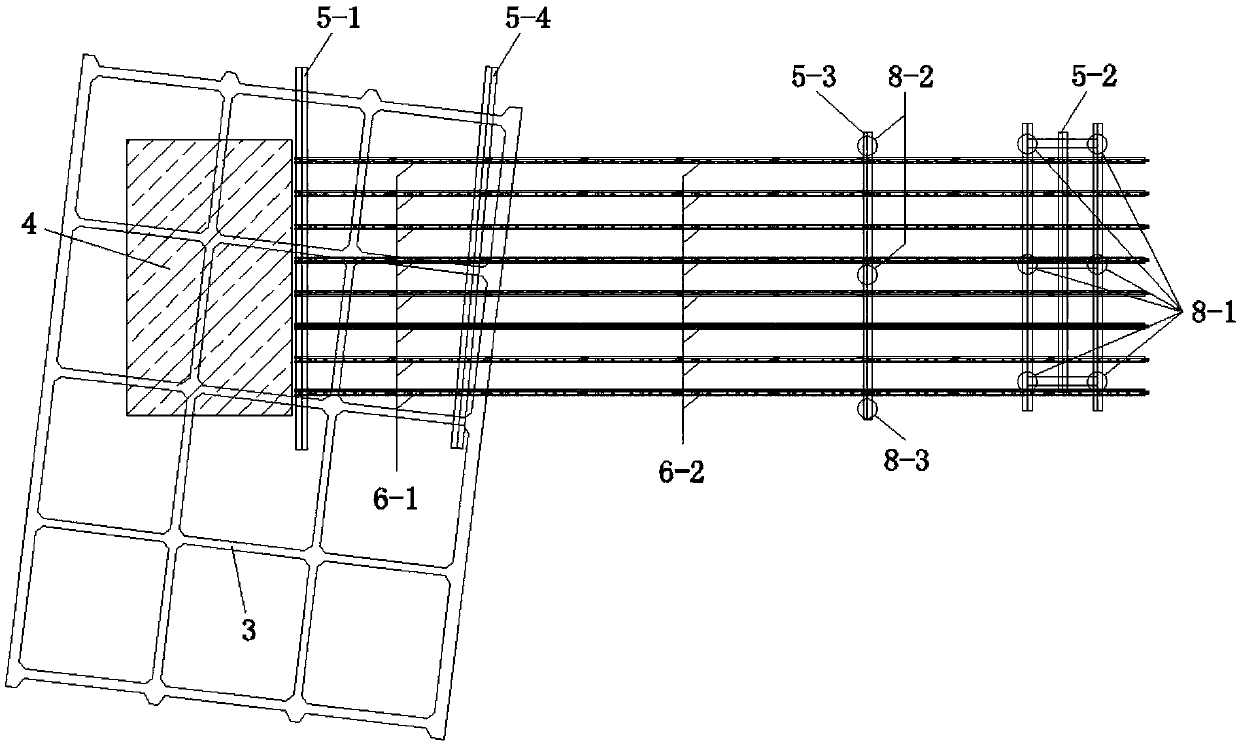

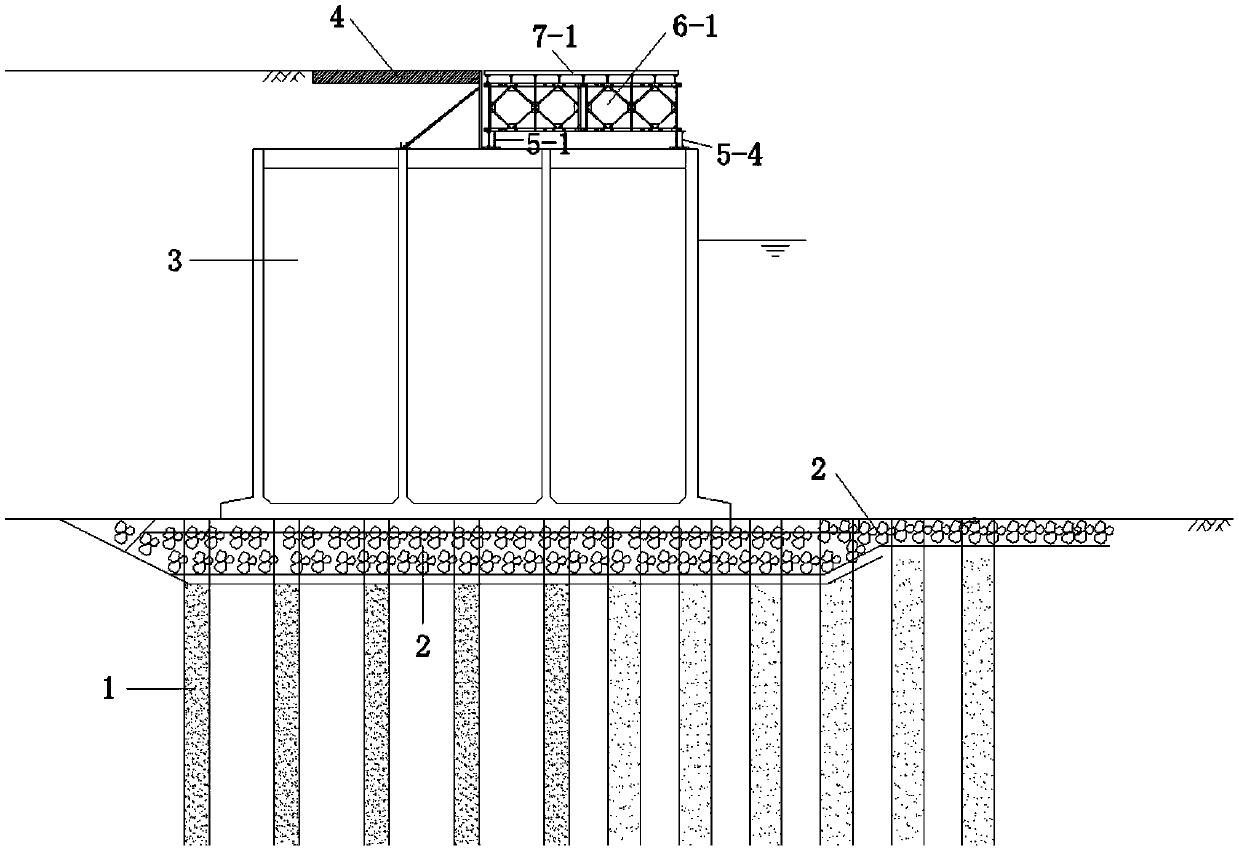

[0068] A method for treating a riprap seabed foundation steel pipe pile foundation of the present invention comprises the following steps:

[0069] (1) Use a pontoon-type pile driver to drive multiple sand piles 1 on the seabed at the design position of the sand piles, make a riprap foundation 2 on the top surface of all the sand piles 1 and level them, and install a prefabricated foundation on the riprap foundation 2. Reinforced concrete caisson 3, and adjust the plane position coordinate error of the bottom surface of the prefabricated reinforced concrete caisson 3 within 100mm, and adjust the top elevation error of the prefabricated reinforced concrete caisson 3 within 100mm;

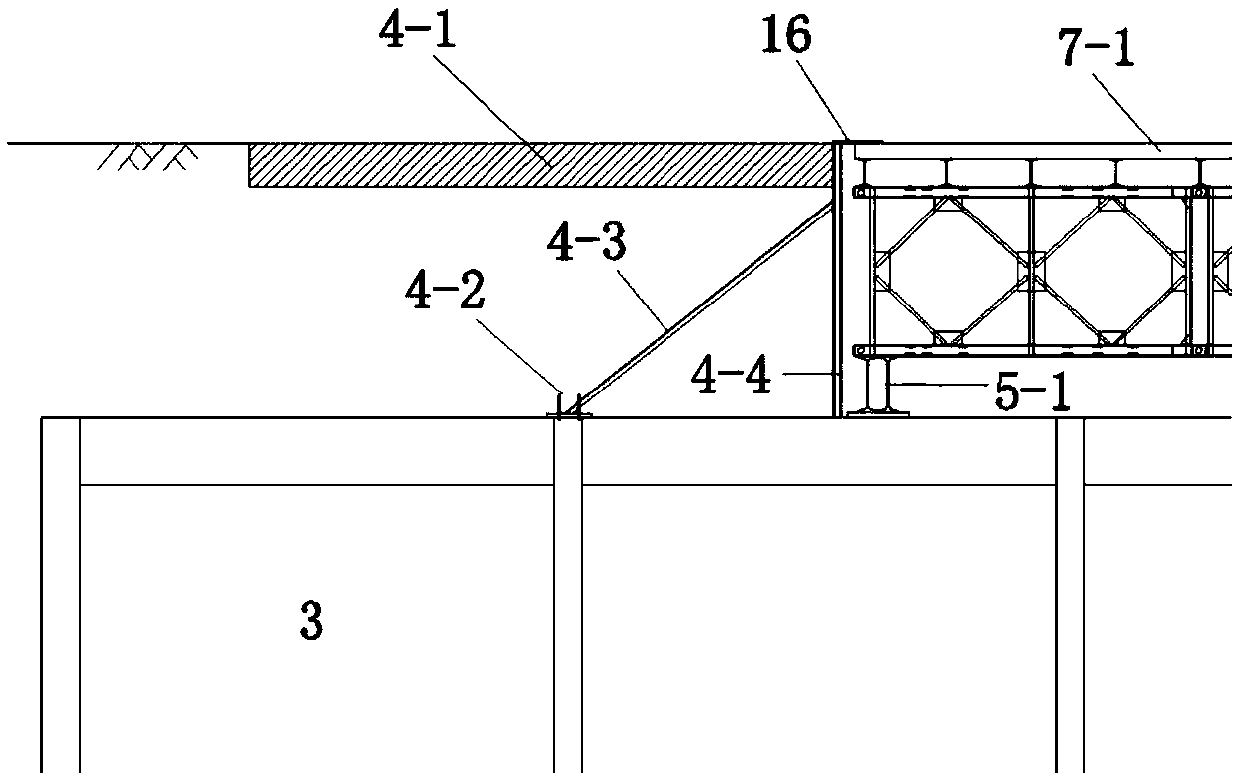

[0070] (2) On the described prefabricated reinforced concrete caisson 3 and on the left side of the left beam end connecting the first span Bailey beam 6-1, the construction of the bridge abutment 4 is carried out, and the described bridge abutment 4 construction includes: at the distance from the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com