Self-resetting steel frame-CLB filler wall and preparation method thereof

A steel frame and infill wall technology, applied in structural elements, building components, building materials, etc., can solve problems such as unsatisfactory sustainable development, difficulty in hoisting, self-heavy, etc., achieve simple construction, improve seismic performance, and reduce residual deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in this description, take a cube as an example, its length direction is the left-right direction, and its The width direction is the front-back direction, and the height direction is the up-down direction.

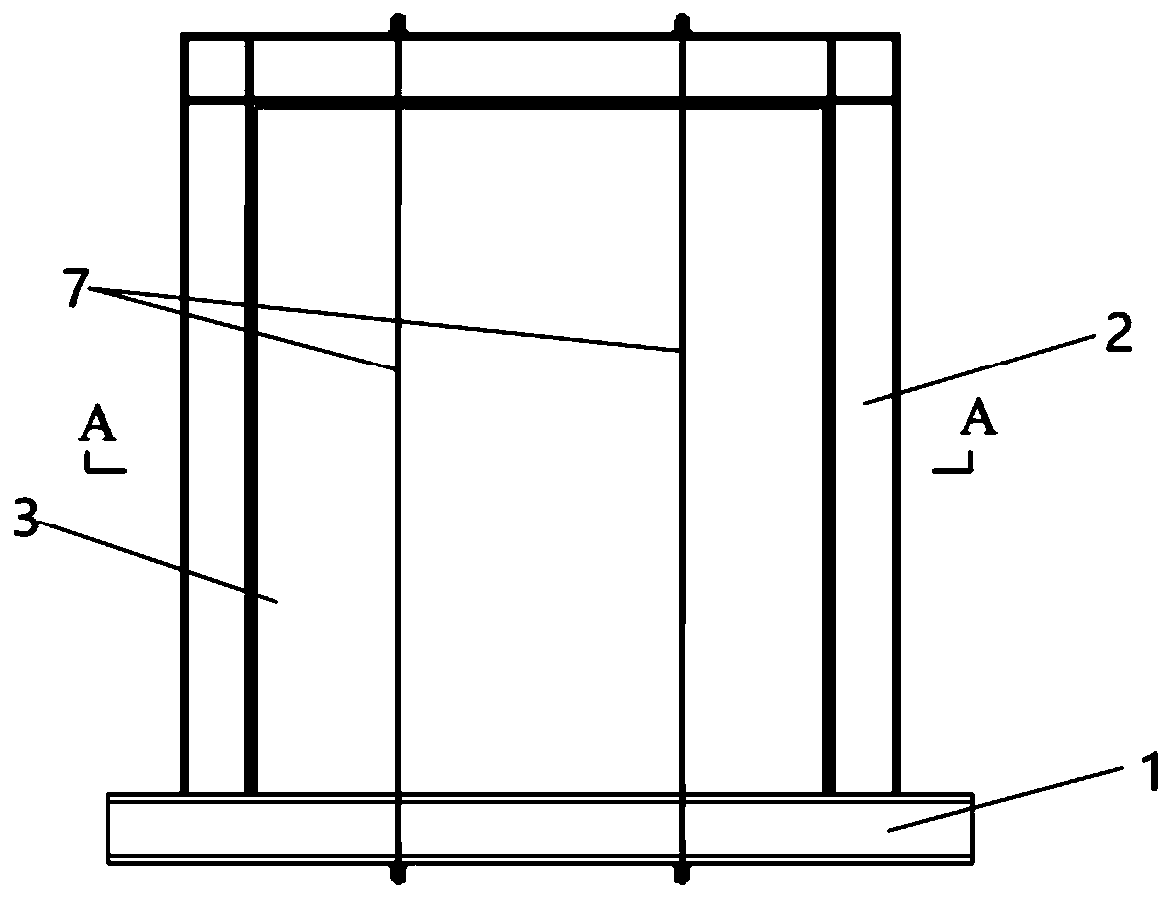

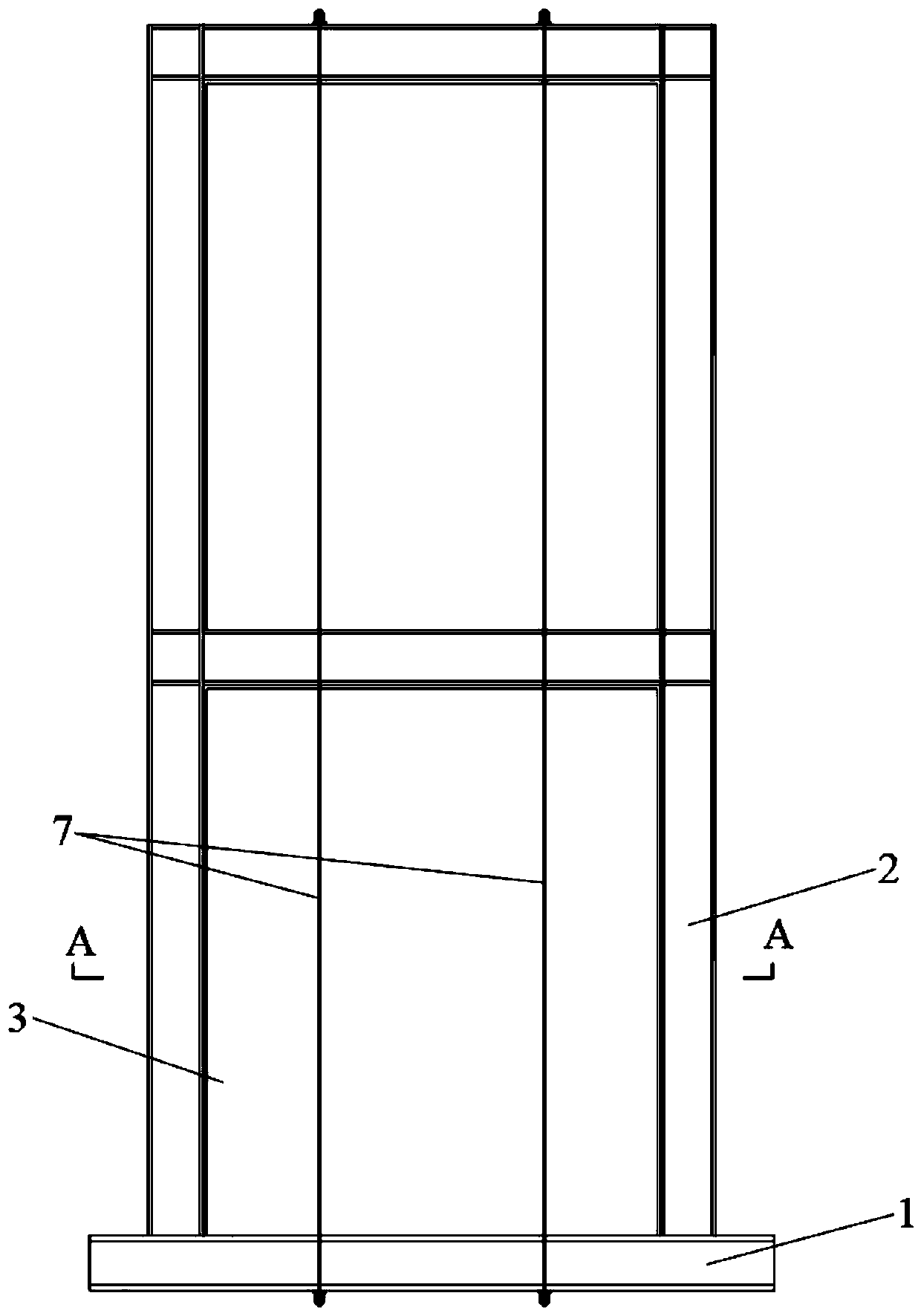

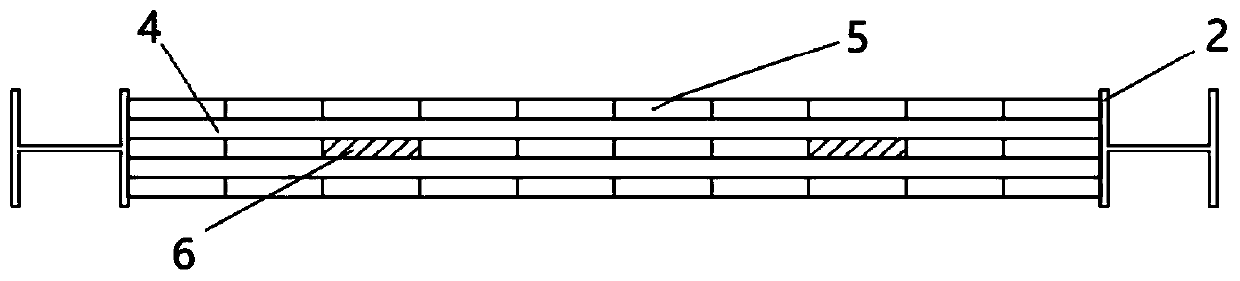

[0017] Such as figure 1 and figure 2 As shown, the self-resetting steel frame-CLB filling wall of the present invention includes a foundation steel beam 1, a steel frame that is arranged on the foundation steel beam 1 and is composed of a frame column and a frame beam arranged at the upper end of the frame column 2. The steel frame 2 can be stacked with several layers up and down in sequence, such as single layer, double layer or multi-layer, which can be determined according to actual needs, and the cross-laminated bamboo wall panels 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com