Multi-layer metal/resin gear, as well as manufacturing process and application thereof

A multi-layer, resin technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as poor fit between the axle and the hub, complicated manufacturing process, and insufficient strength of the gears, etc. , to achieve the effect of saving material cost, low elastic rate and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

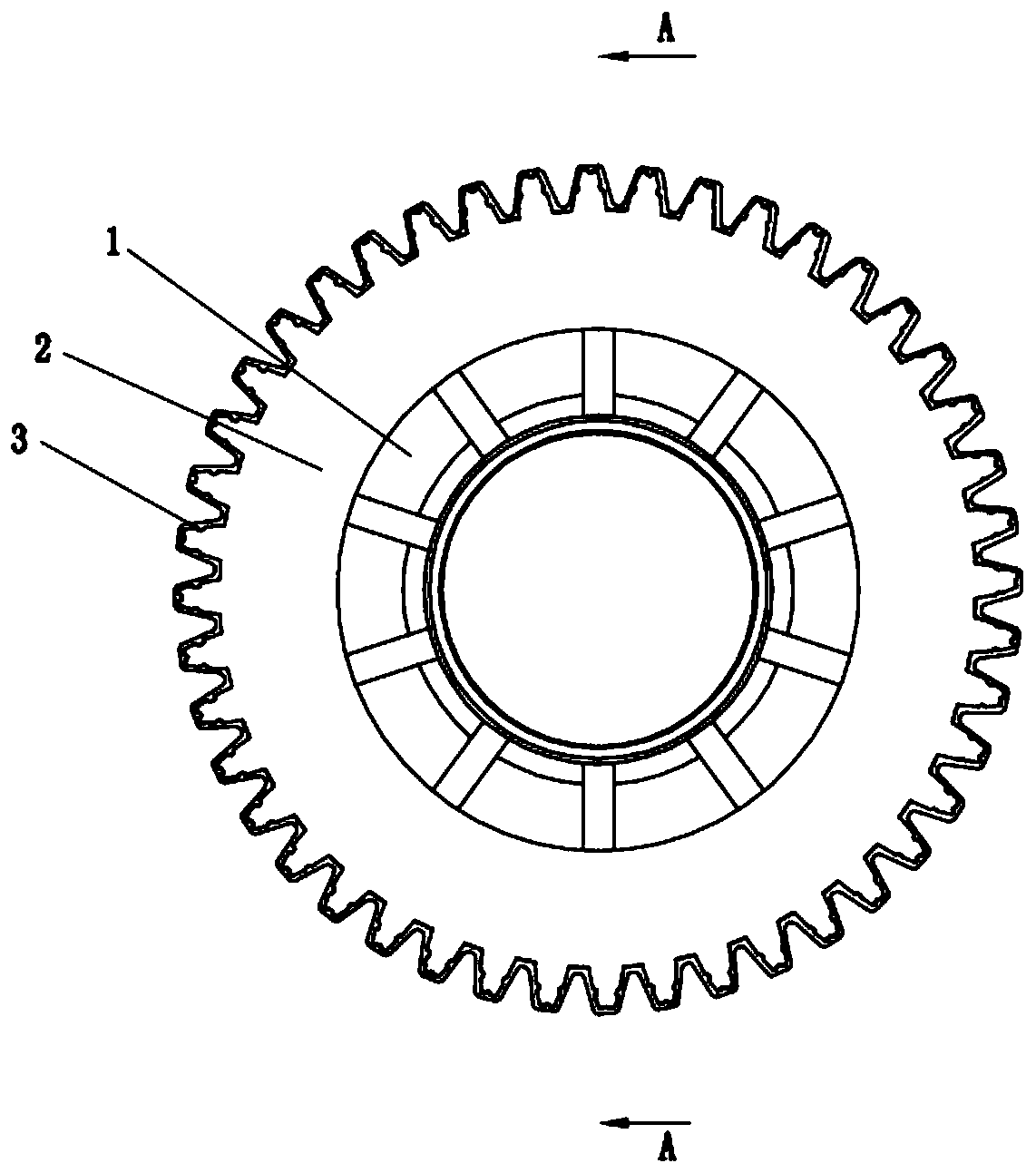

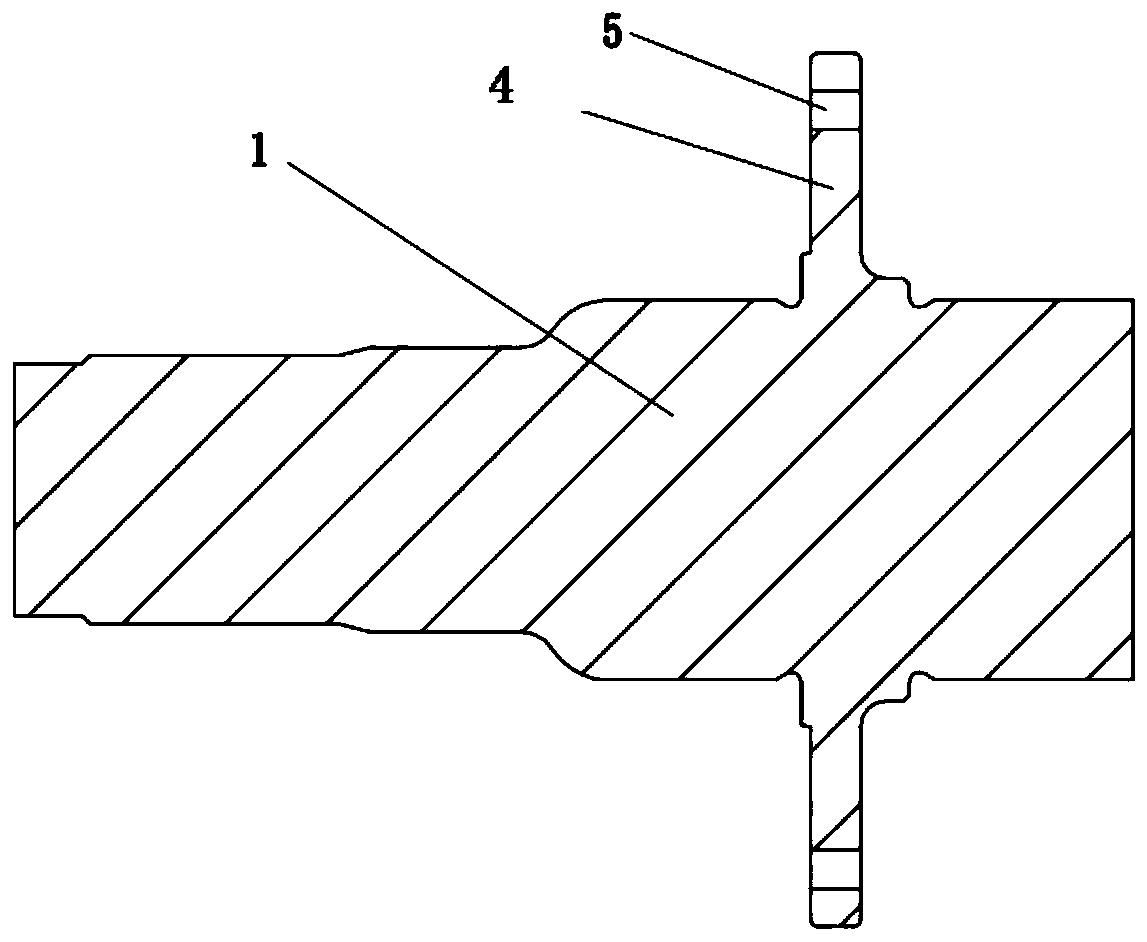

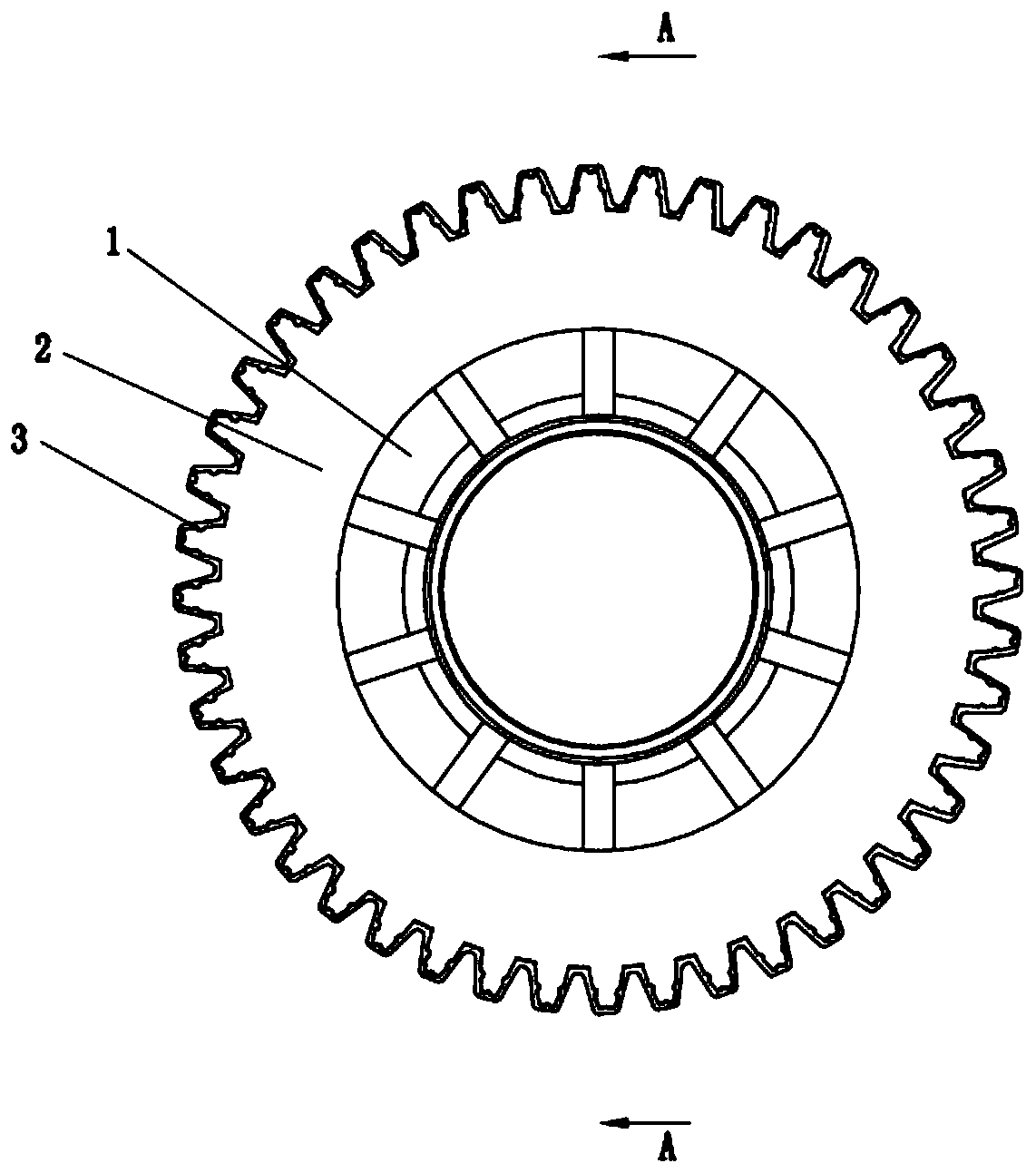

[0053] Carbon steel is used to manufacture an integrally formed metal core with an axle portion and a hub portion by casting, and the outer diameter of the axle portion is 30mm. The hub portion has an outer diameter of 70 mm and a thickness of 4 mm. There are 16 through holes evenly distributed along the circumference, with a diameter of 5 mm, arranged on the outer side of the hub portion. The finished metal core is placed in an injection mold. A fiber reinforced polyamide resin is injected to form a support ring surrounding the outer periphery of the hub portion, the resin filling the through holes. A plurality of grooves are arranged on the end surface and the tooth surface of the protruding teeth of the support ring. Then, wrap PA66 resin on the outer peripheral surface of the support ring to form the outer gear layer. The support ring and the outer tooth layer constitute the ring gear part, which has an outer diameter of 90 mm, a thickness of 18 mm, and 44 teeth. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com