Driving shaft system rack test device and method for automobile

A bench test, drive shaft technology, applied in the direction of measuring device, vehicle test, machine gear/transmission mechanism test, etc. problems such as product quality, to achieve the effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

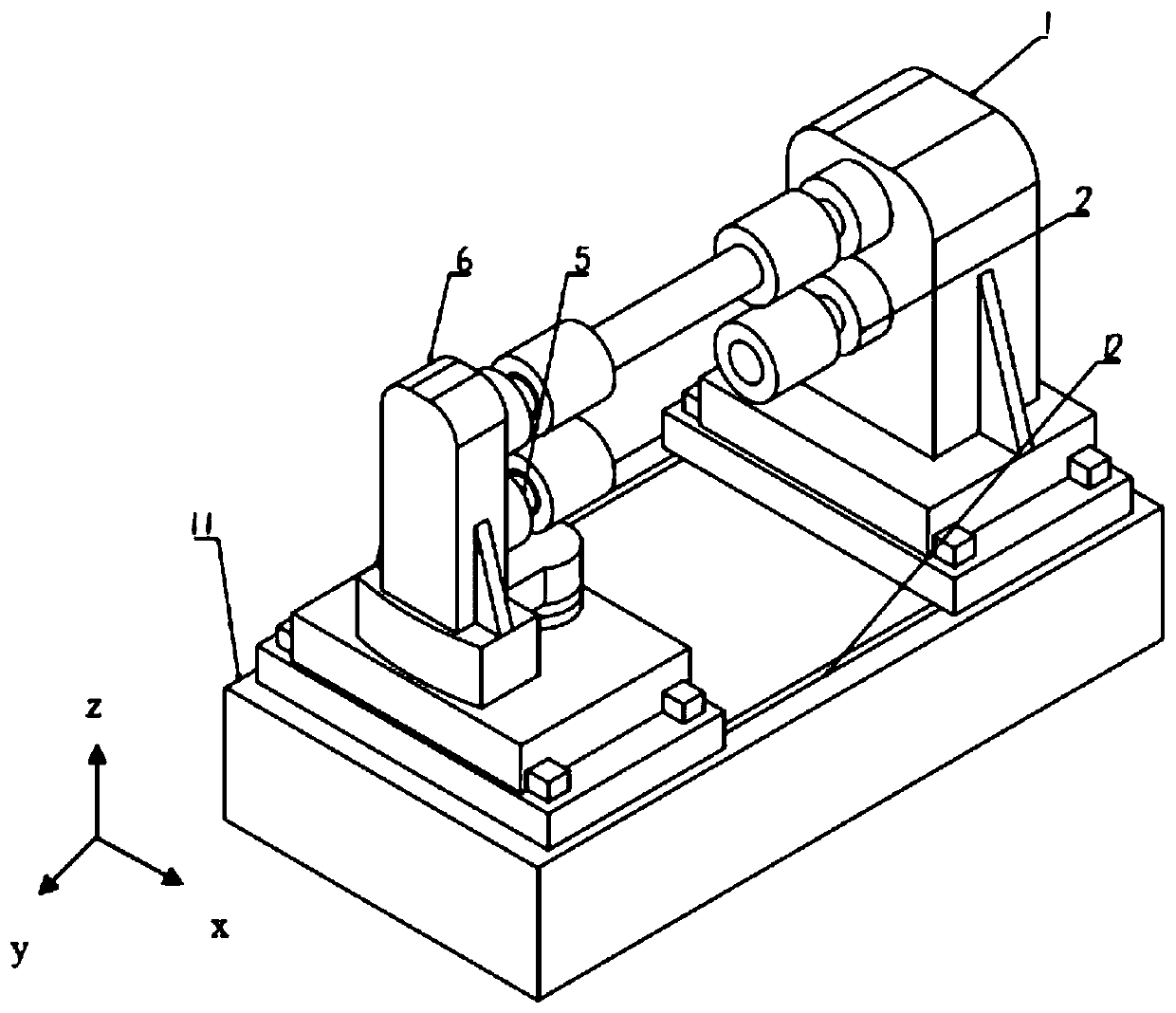

[0045] In order to better understand the present invention, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

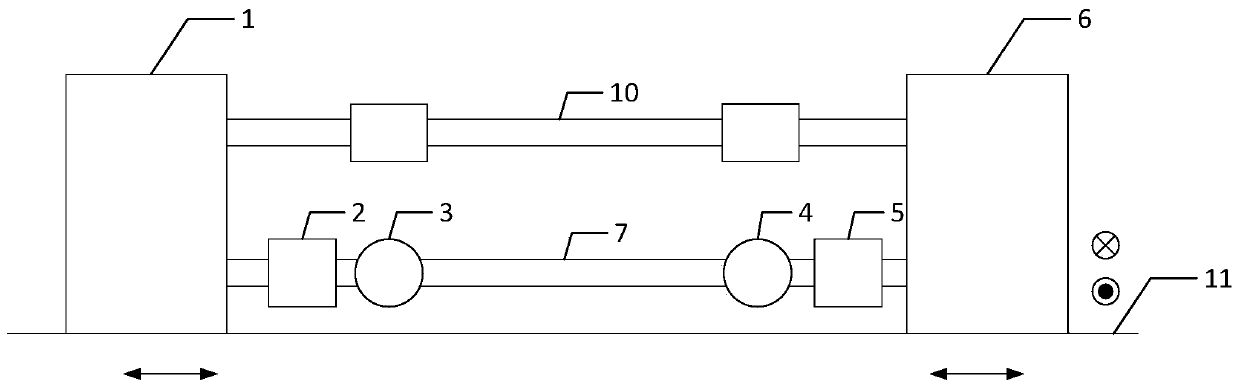

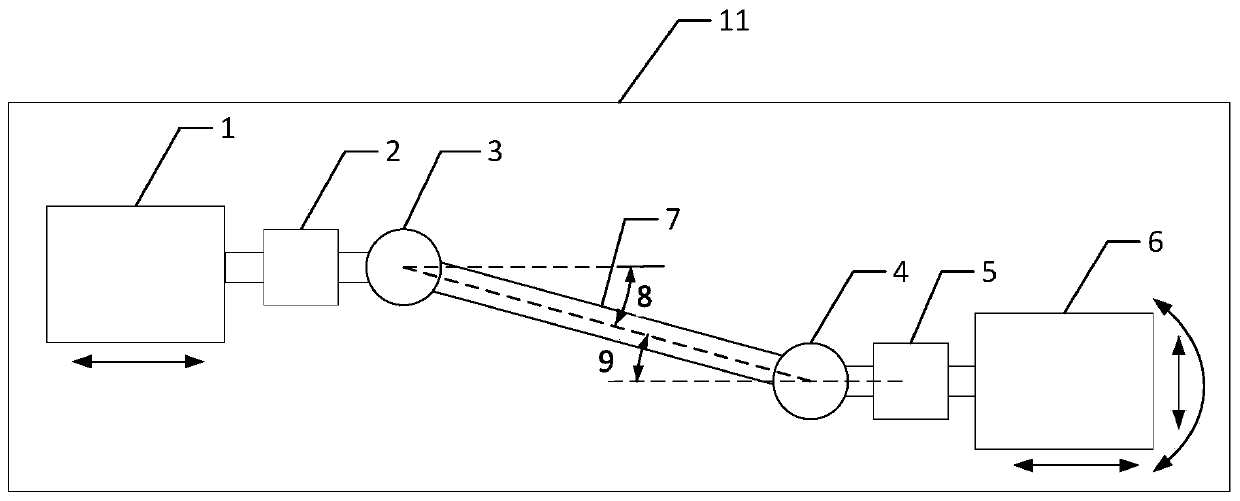

[0046] Such as Figure 1 to Figure 3 As shown, a bench test device for a drive shaft system for an automobile includes:

[0047] Base 11, the upper end surface of which is provided with two base Y-direction chute 12 in parallel along the length direction;

[0048] Relative to the drive motor mechanism 1 and the load motor mechanism 6 arranged on the upper end surface of the base 11, the drive motor mechanism 1 and the load motor mechanism 6 are both provided with upper and lower shaft clamps, wherein the upper two-axis clamp A secondary shaft 10 with universal joints at both ends is connected between them, and the two-axis clamps at the bottom of the drive motor mechanism and the load motor mechanism are respectively provided with a Y-direction force sensor 2 and a torque sensor 5; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com