Automatic adapter corner weld seam phase controlled array detection device capable of scanning in two ways

A detection device, phased array technology, applied in the direction of measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, using sound wave/ultrasonic wave/infrasonic wave to analyze materials, etc., can solve the problem that the detection cannot be implemented, and the detection of fillet joint joints is not involved method, unable to guarantee the completion of the detection work, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

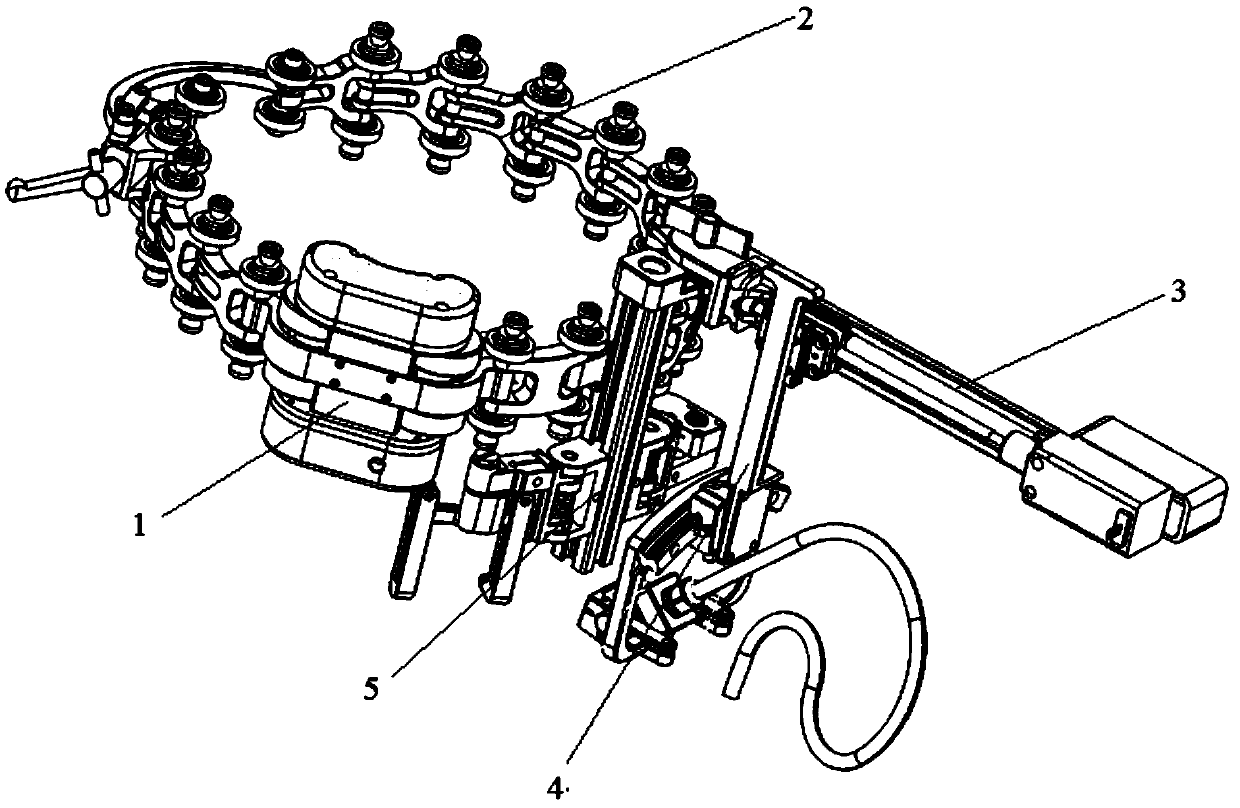

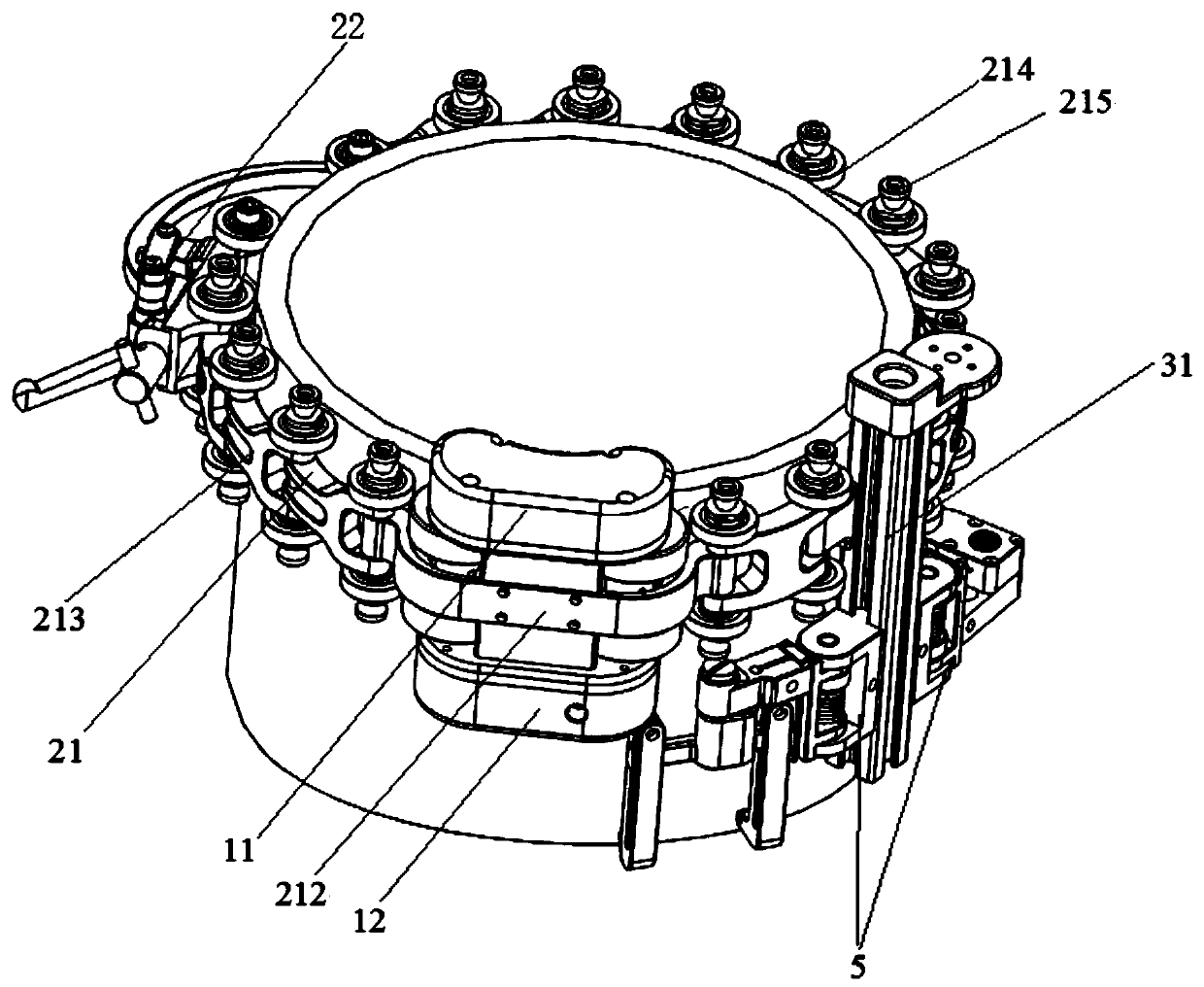

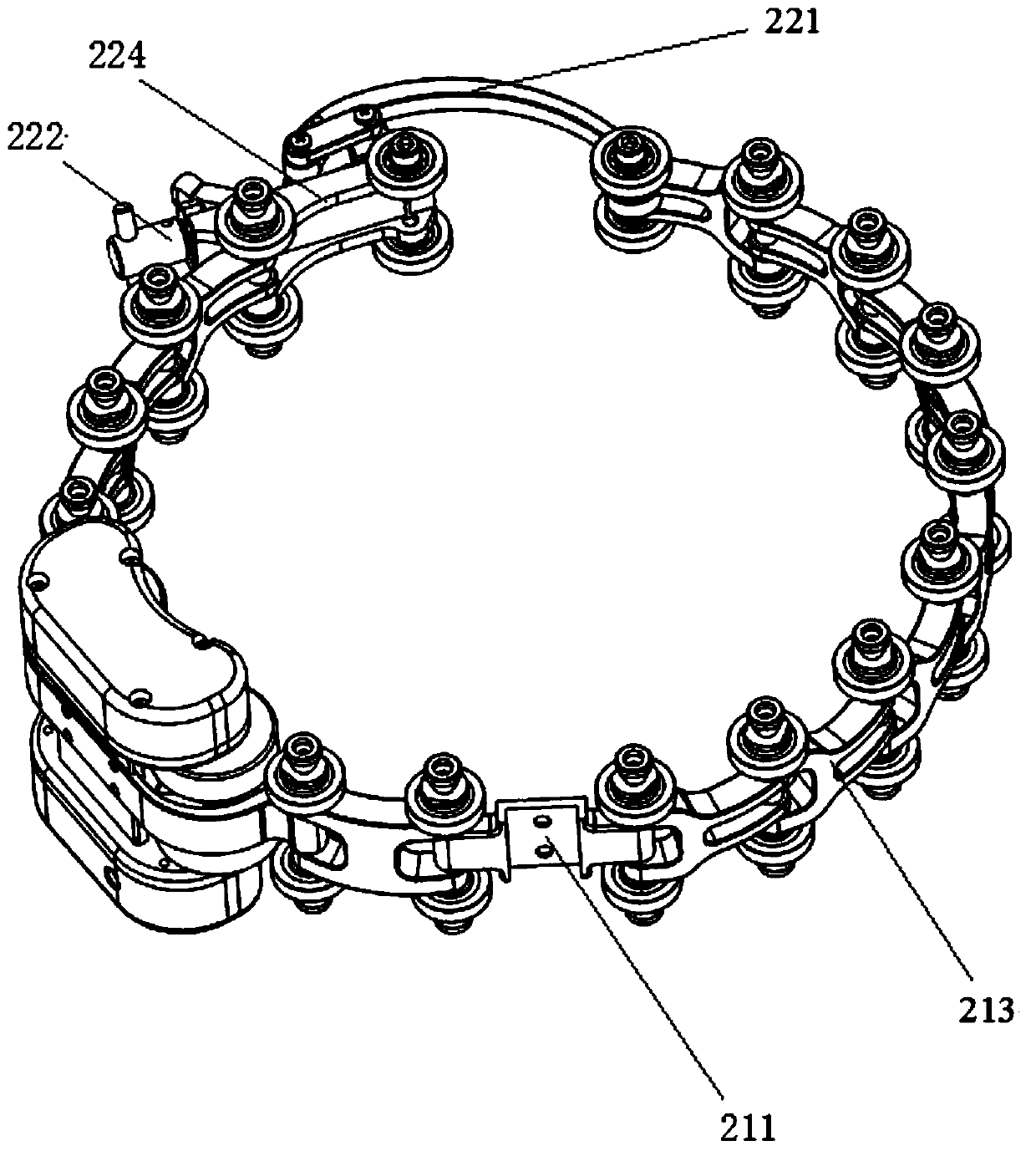

[0046] like Figure 1-11 As shown, a phased array detection device for automatic fillet weld seam that can scan bidirectionally in this patent includes a traveling mechanism 1, a locking mechanism 2, an automatic adjustment module 3, a probe frame slide bar assembly 4, and a tube probe arm 5. Control mechanism.

[0047] The traveling mechanism 1 includes two sets of front and rear traveling wheels, a drive motor 11 and a displacement sensor 12; the traveling mechanism 1 is connected to the locking mechanism 2 and arranged on the outer edge of the connecting pipe, and the driving motor 11 and the displacement sensor 12 are respectively arranged on both sides of the traveling mechanism 1; The driving motor 11 drives the traveling wheel to drive the entire scanning device to move clockwise or counterclockwise along the outer diameter of the connecting pipe; the displacement sensor 12 collects the moving distance of the traveling wheel on the outer edge of the connecting pipe and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com