Miniature liquid metal switch with flexible structure

A liquid metal, flexible structure technology, used in electrical switches, electrical components, circuits, etc., can solve the problems of limiting switch on-off time, increasing line loss, large contact resistance, etc., achieving fast on-off and closing speed, reducing Contact resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

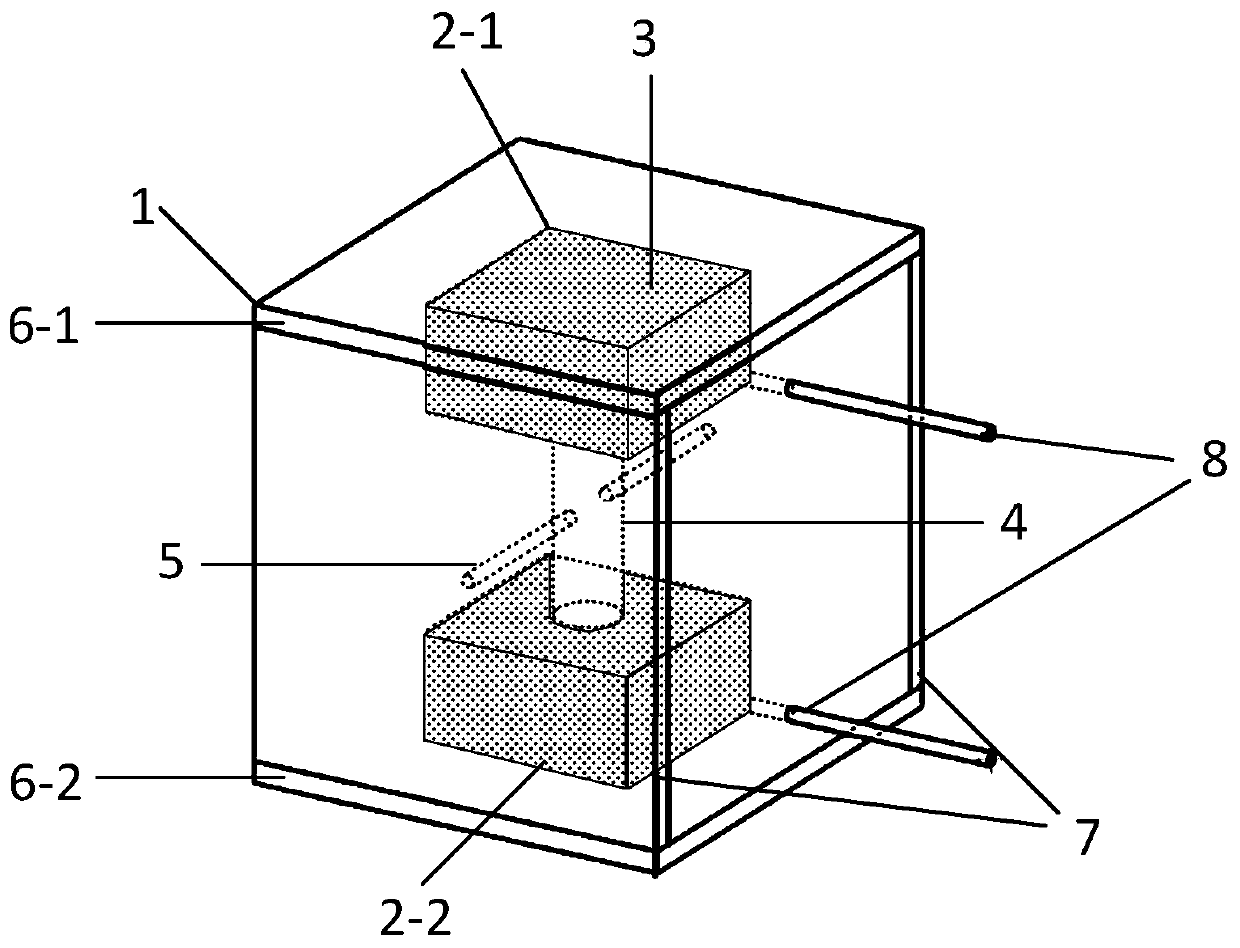

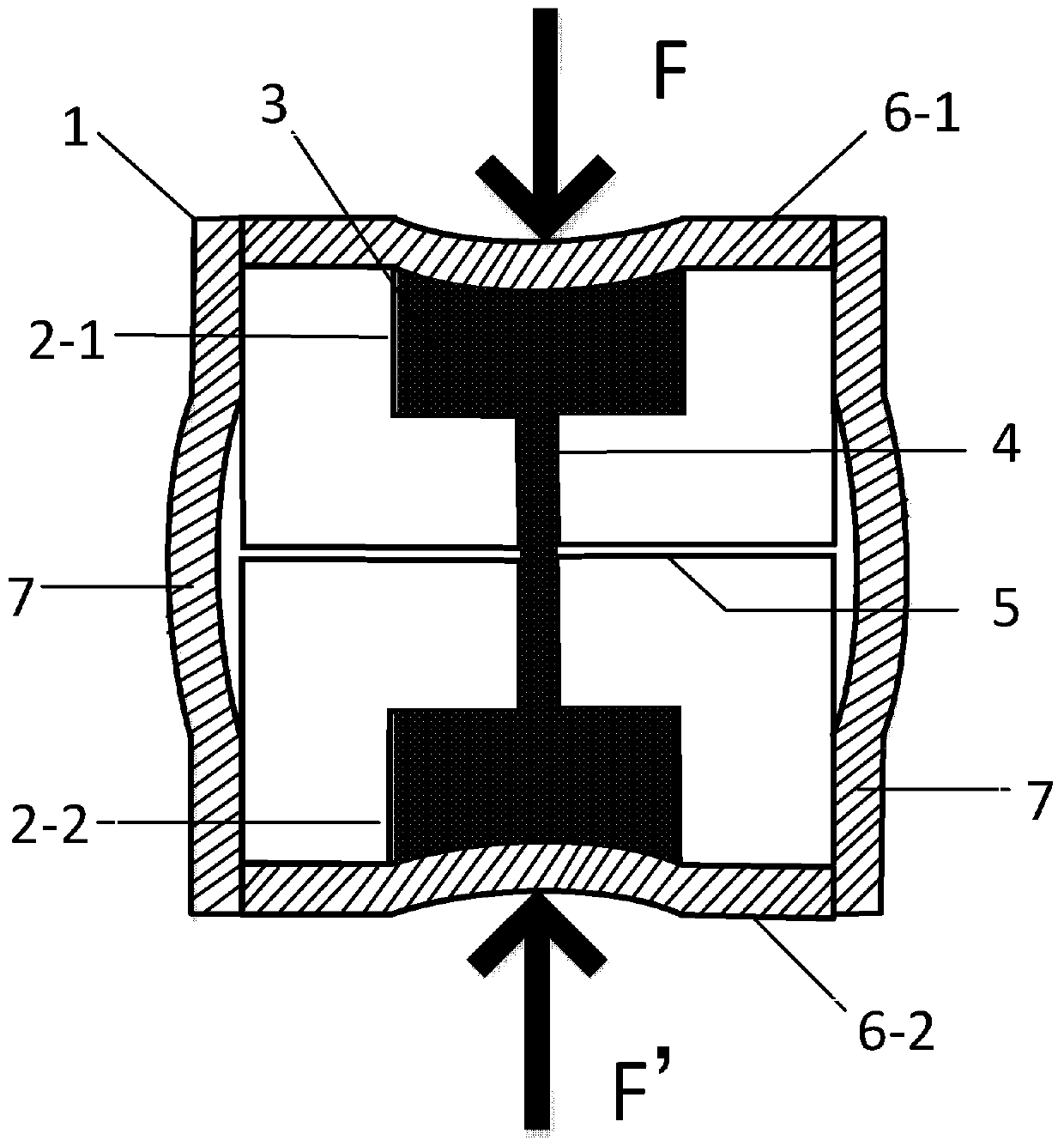

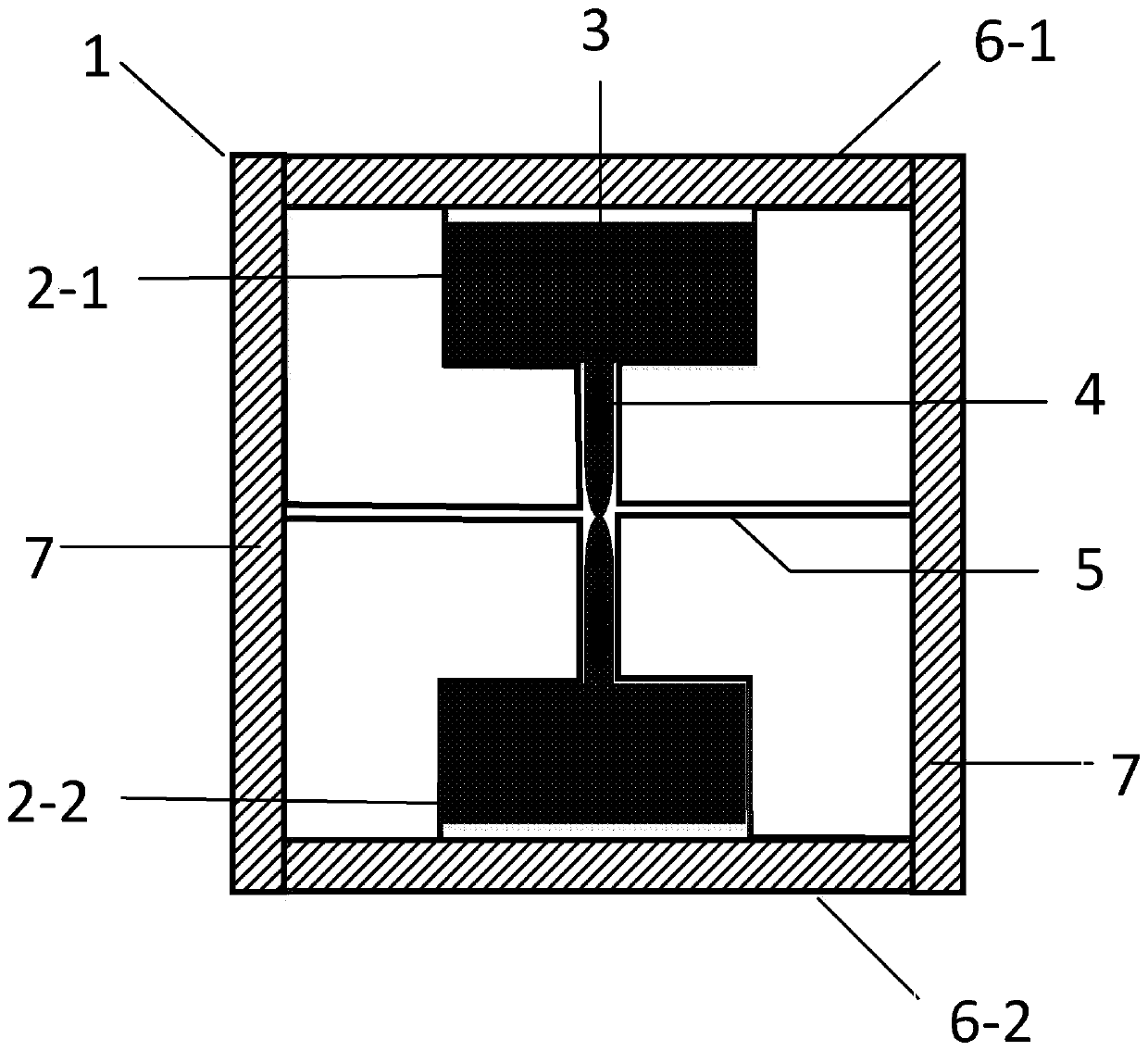

[0036] Attached below Figure 1 to Figure 5 The technical solutions of the present disclosure will be described in detail with the examples, and the following examples are only illustrative and not intended to limit the present disclosure.

[0037] see figure 1 , a miniature liquid metal switch with a flexible structure, extruding the high-elastic matrix through external mechanical stress to promote the movement of the liquid metal to connect the circuit, through the automatic rebound of the high-elastic matrix material and the contraction of the surface tension of the liquid metal to achieve rapid circuit breaking, including: the matrix 1. Upper liquid storage tank 2-1, lower liquid storage tank 2-2, liquid metal 3, liquid metal flow channel 4, air flow channel 5, top sealing film 6-1, bottom sealing film 6-2, side sealing Thin film 7 and external electrode 8; Wherein,

[0038] The upper reservoir 2-1 is located on the side of the substrate 1 covered with the top sealing fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com