Method for cutting, intensive trenching and returning-to-field of crop straw or green manure crop and associated equipment

A technology of green manure crops and crop stalks, applied in the agricultural field, can solve the problems of increased greenhouse gas emissions, poor quality of overturning, insufficient depth of burial of straws, etc., and achieve the effects of digestion, plowing and fertilization, simple and convenient operation, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

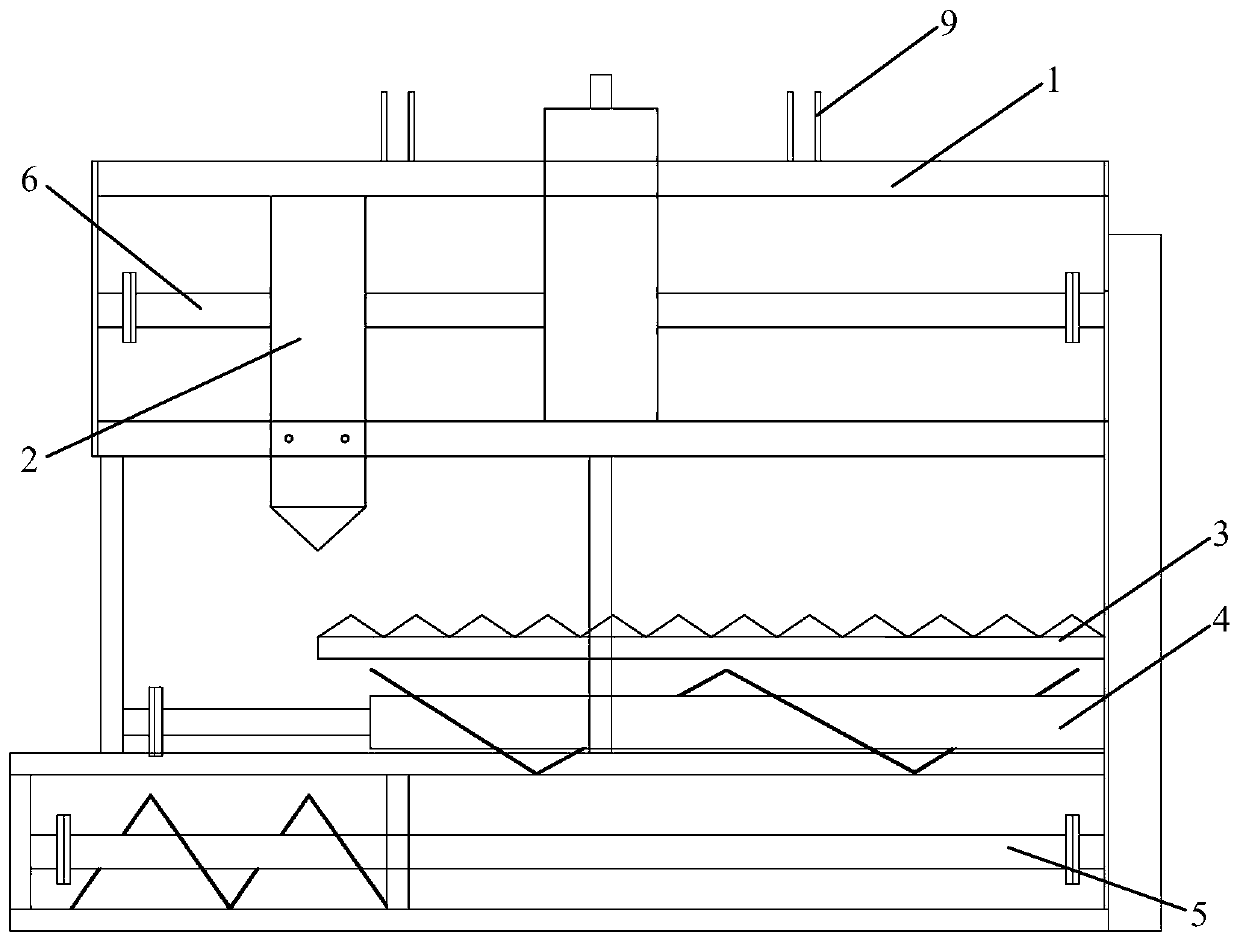

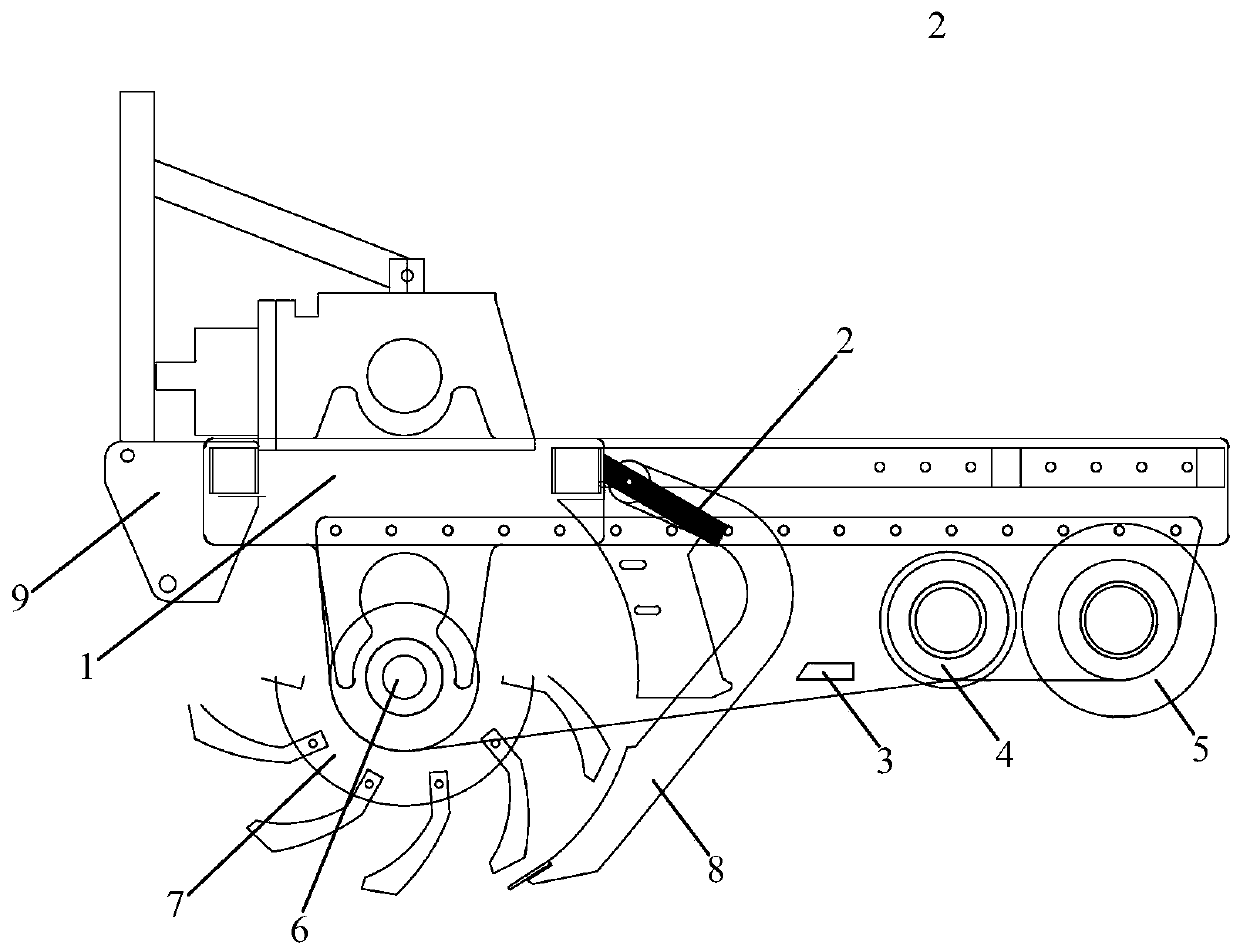

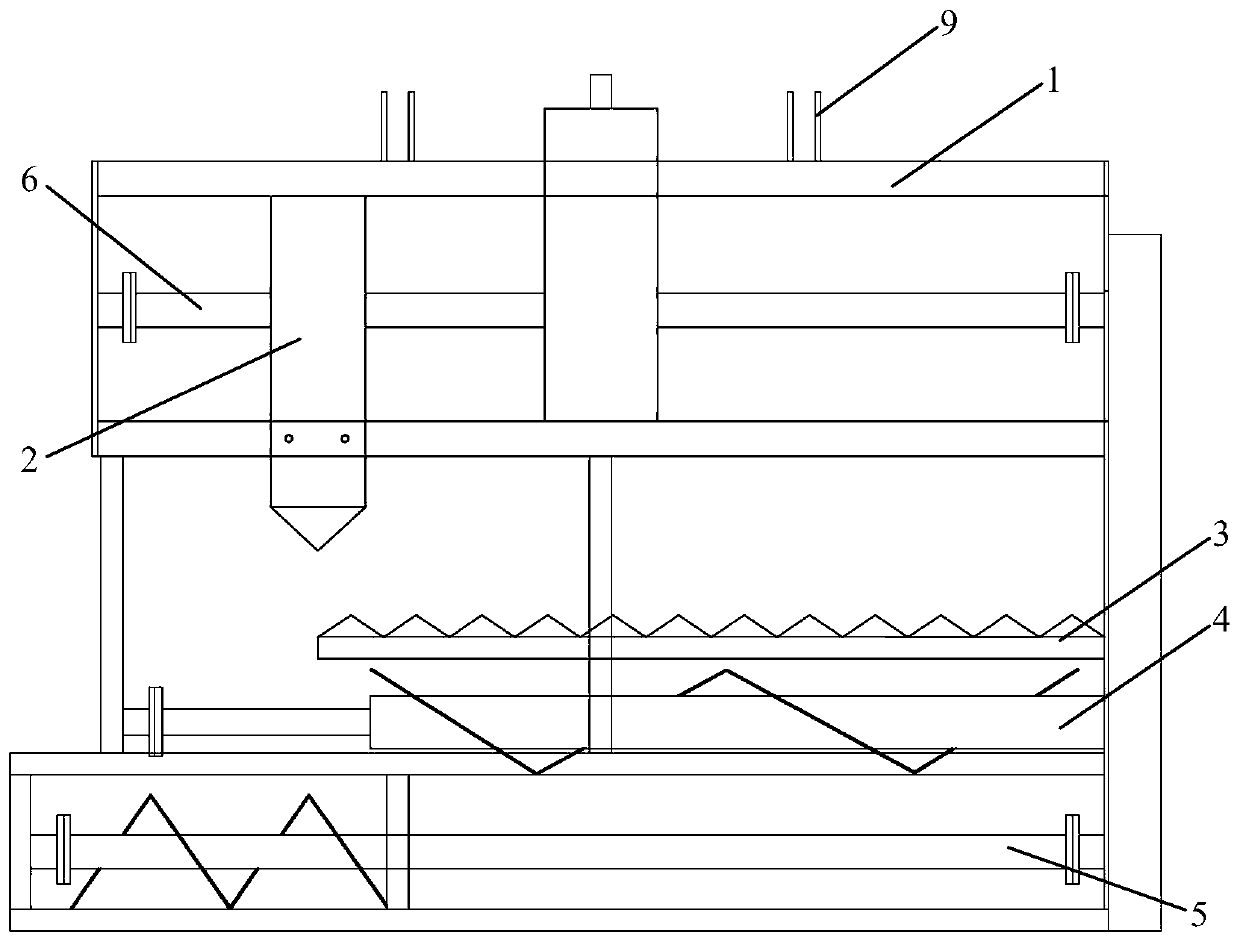

[0033] In order to avoid obstacles such as tillage and fertilization, sowing and emergence of crop stalks or green manure crops caused by plowing or mulching and returning to the field, the inventor proposes a method for crop stalks or green manure crops to be cut and concentrated in trenches and returned to the field, which is characterized in that it includes the following steps :

[0034] (1) digging a landfill ditch in the field and placing the excavated soil on the edge of the landfill ditch;

[0035] (2) cutting down the crop stalks or green manure crops in the field;

[0036] (3) transporting the crop stalks or the green manure crops to the landfill ditch;

[0037] (4) Backfill the excavated soil in the landfill ditch and compact it.

[0038] In the step (1), the width and depth of the buried ditch can be determined as required, preferably, in the step (1), the width of the buried ditch is 20 cm to 30 cm, The depth of the buried ditch is 25 cm to 40 cm.

[0039] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com