Well cellar-type transplanting method for flue-cured tobacco

A well-pit type, flue-cured tobacco technology, applied in the field of flue-cured tobacco cultivation, can solve the problems of difficulty in hiring and expensive labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

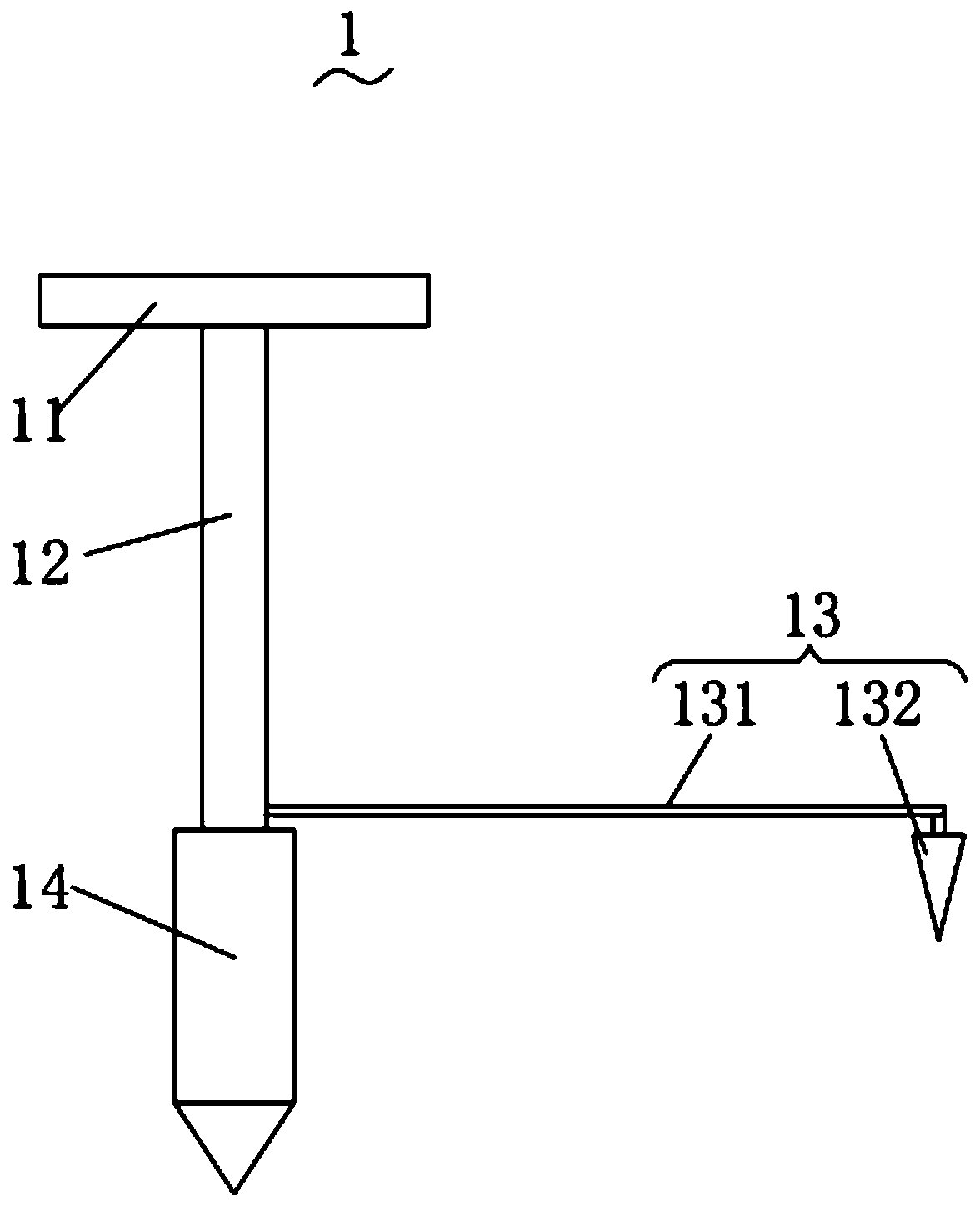

[0034] The tobacco field is located in a hilly area, with an area of 12 mu, and the soil type is brown soil; using drip irrigation instead of manual watering to transplant flue-cured tobacco in a cellar, the operation steps are as follows:

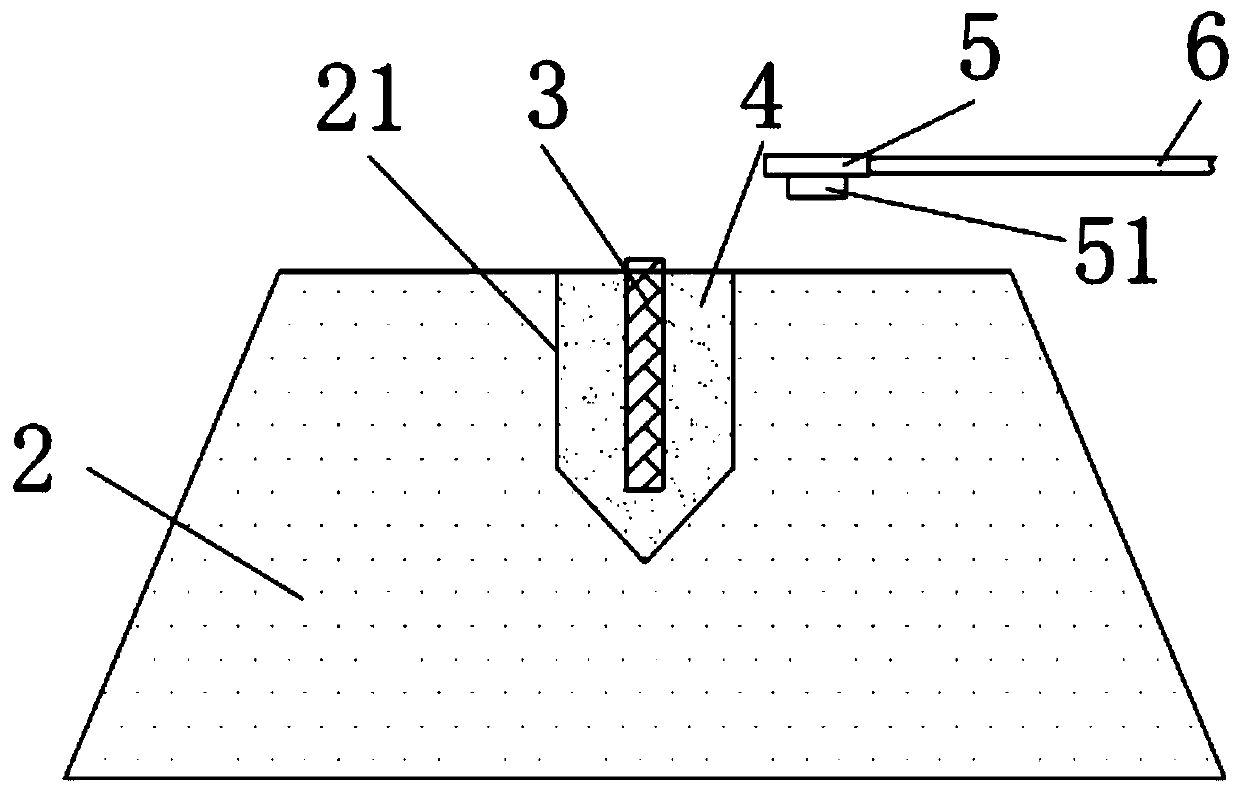

[0035] (1) Ridging started on April 10, and the ridge distance between the adjacent smoke ridge 2 was 110cm; the ridge height of smoke ridge 2 was 26cm, the ridge top width was 30cm, and the ridge bottom width was 75cm; The depth is the same, the soil is broken, the top is empty and the bottom is solid, and the ridges are full.

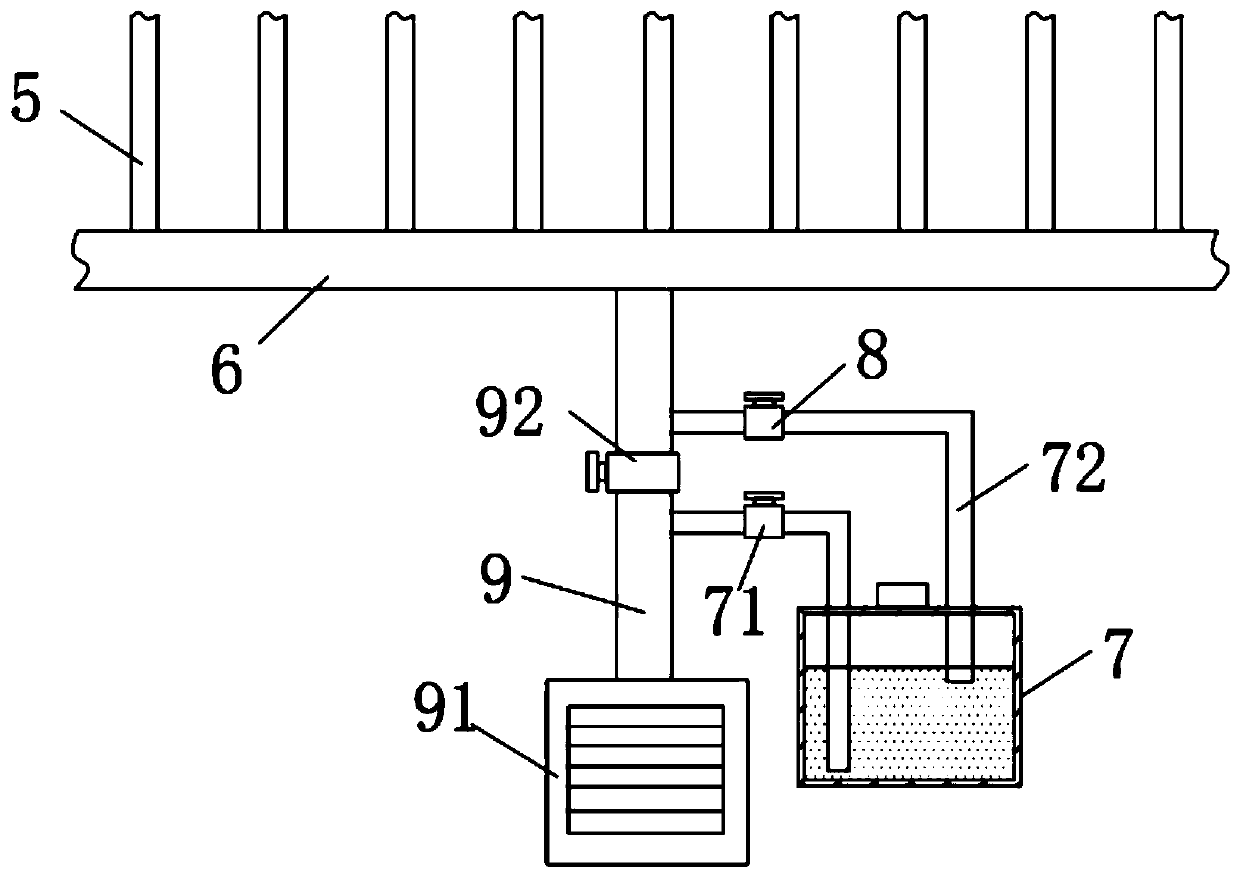

[0036] (2) After ridge formation, install a drip irrigation system on the top of the smoke ridge 2; use a JT10-A laminating machine to cover the smoke ridge 2 to protect the smoke ridge 2; the distance between the drip irrigation belt 5 and the top of the smoke ridge 2 Face center 10cm, drip irrigation belt 5 selects sheet type for use, dripper 51 pitches 30cm.

[0037] (3) Moisture creation means artificial wa...

Embodiment 2

[0041] The tobacco field is located in the plain area. It is a continuous square plot with an area of 50 mu. The soil type is cinnamon soil. The method of transplanting flue-cured tobacco in a cellar using drip irrigation instead of manual watering is as follows:

[0042] (1) From April 15th to 16th, use a ridging machine to raise the ridges. The ridge distance is 120cm, the ridge height is 30cm, the ridge top width is 35cm, and the ridge bottom width is 80cm; the ridge body is full after ridging.

[0043](2) From April 17th to 18th, use the film-covered drip irrigation tape laying machine (the slyzj-4 type produced by Qufu Hongyin Machinery Equipment Co., Ltd.) to lay the drip irrigation tape and film. The selected drip irrigation tape is a labyrinth of flanks , dripper spacing 30cm;

[0044] (3) The moisture content before transplanting was average, using drip irrigation to create moisture, watering for 2 hours in total, no dry soil was seen on the top of the ridge; at the...

Embodiment 3

[0048] The tobacco field is located in a mountainous area, with an area of 5 mu. The soil is sandy soil. The flue-cured tobacco is transplanted in a cellar using drip irrigation instead of manual watering. The operation steps are as follows:

[0049] (1) On April 20, a small ridging machine in mountainous areas was used to form a ridge, with a ridge distance of 110cm, a ridge height of 25cm, a ridge top hip of 30cm, and a ridge bottom width of 70cm;

[0050] (2) Lay the drip irrigation belt and cover it immediately after the ridge is formed. The drip irrigation belt is a labyrinth of flanks, and the distance between the drippers is 20cm;

[0051] (3) The moisture content before transplanting was good, no moisture was created, and there was no water leakage in the drip irrigation belt in the test test;

[0052] (4) Transplanting was carried out on May 5. When transplanting, two staff members drilled holes, planted seedlings, and sealed the hole; the depth of the well cellar m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ridge height | aaaaa | aaaaa |

| Ridge bottom width | aaaaa | aaaaa |

| Ridge height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com