Shoemaking production line of panel-type frame

An assembly line and panel technology, applied in shoemaking machinery, footwear, clothing, etc., can solve problems such as difficult maintenance of the entire shoemaking assembly line, and achieve the effect of easy replacement and installation, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

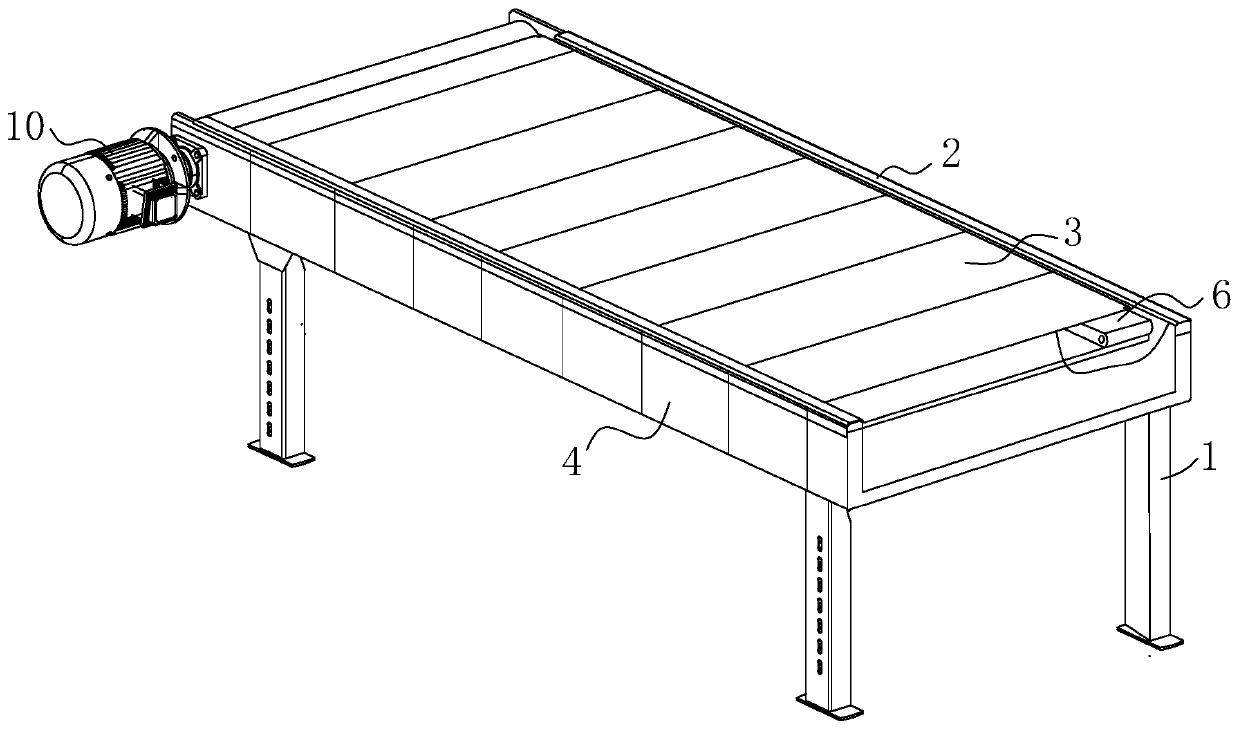

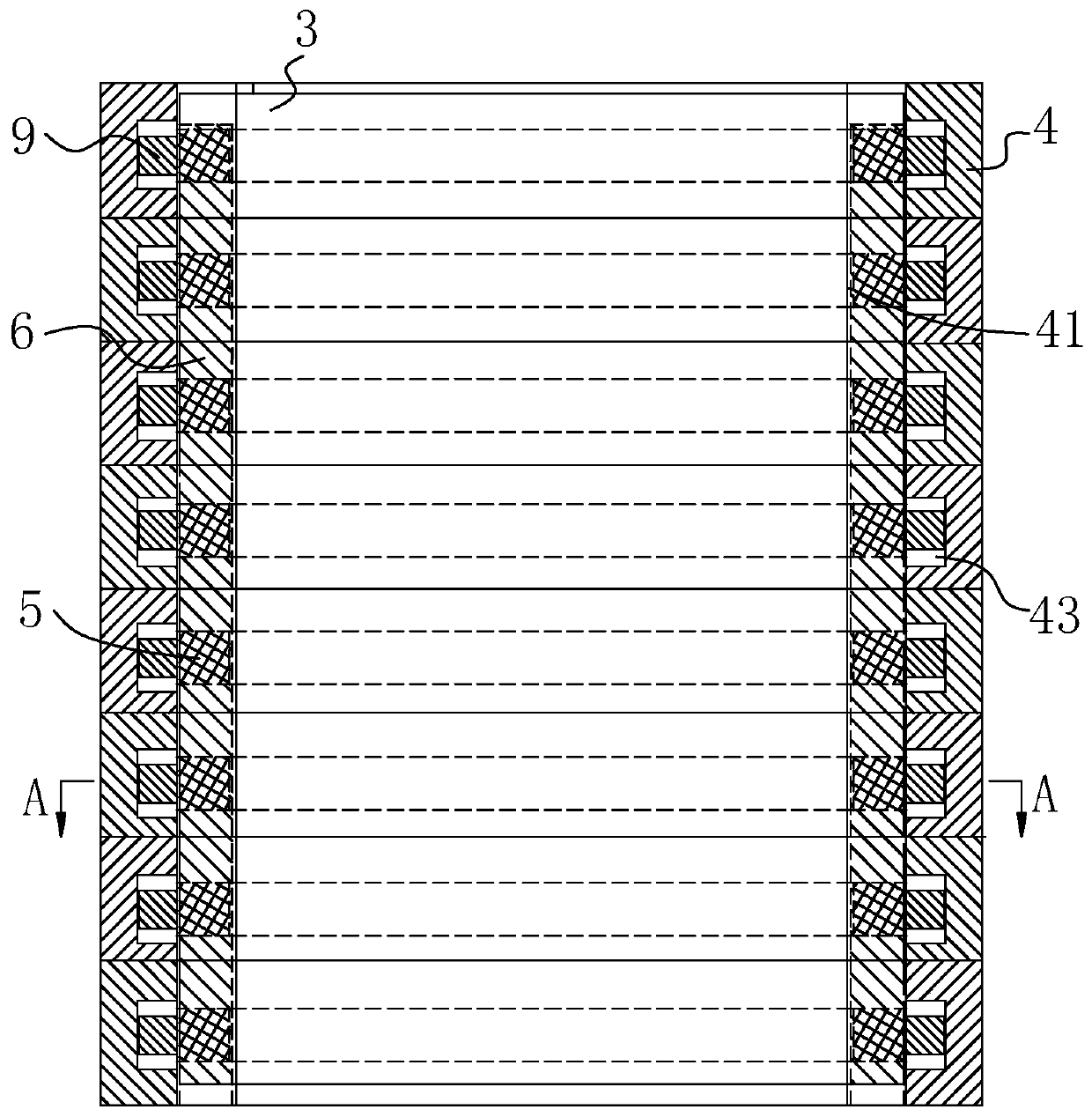

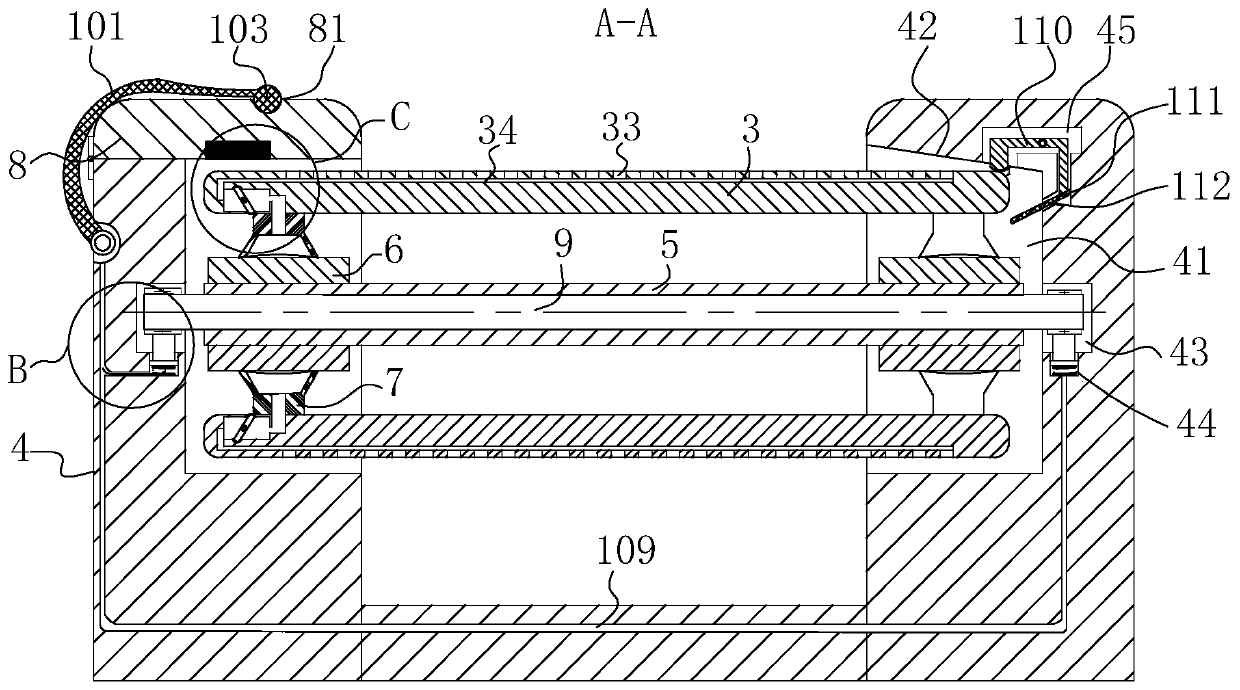

[0023] use Figure 1-Figure 5 A shoe-making line with a panel frame according to an embodiment of the present invention will be described as follows.

[0024] Such as figure 1 , figure 2 and image 3 As shown, a shoe-making line of a panel frame according to the present invention includes a support leg 1, an outer frame 2 and a conveying panel 3; the outer frame 2 is arranged on the support leg 1, and the outer frame 2 is made of multiple The vertical plate 4 is composed of; the vertical plate 4 is provided with a mounting groove 41, and the conveying roller 5 is uniformly arranged in the mounting groove 41, and the outer end surface of the conveying roller 5 is sleeved with a smooth conveyor belt 6; the smooth conveyor belt The outer surface of 6 is evenly equipped with conveying panels 3, and the conveying panels 3 are adsorbed on the outer surface of the smooth conveyor belt 6 by rubber suckers 7; the uniformly arranged conveying panels 3 correspond to the evenly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com