Method for machining reverse bevel gear by variable pressure angle hobbing cutter

A technology of variable pressure angle and inverted bevel teeth, which is applied to elements with teeth, gear teeth, belts/chains/gears, etc., which can solve the problem of increased risk of transmission out-of-gear and reduce the risk of out-of-gear , reduce casting and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

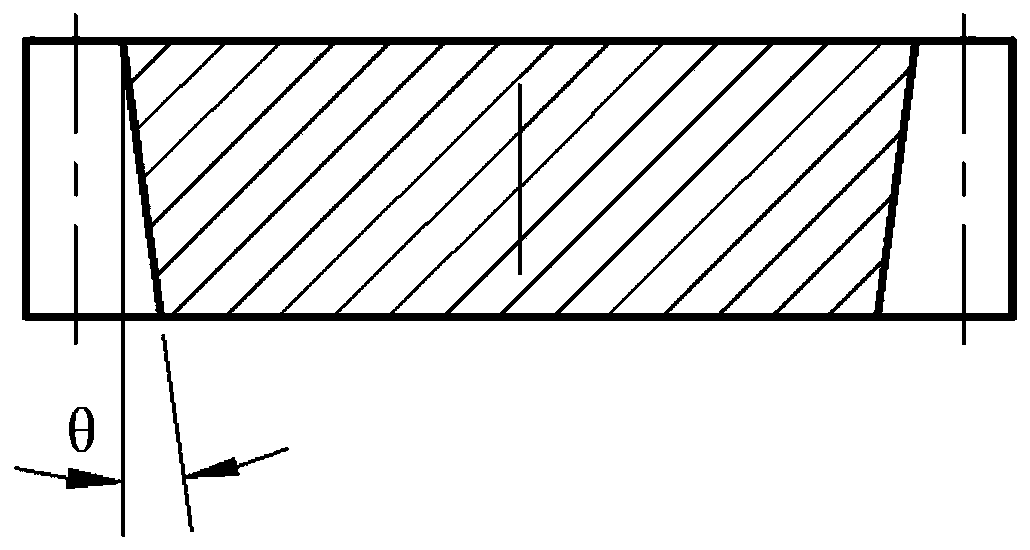

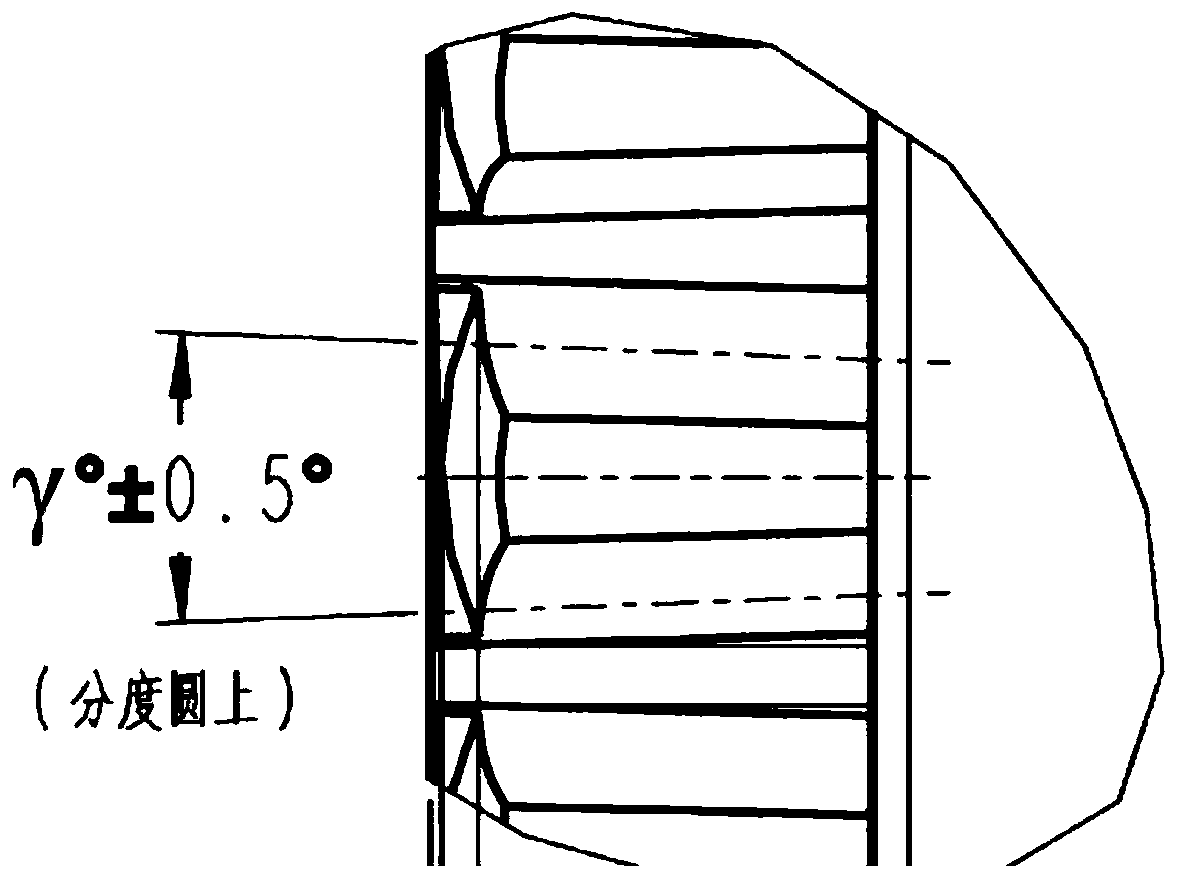

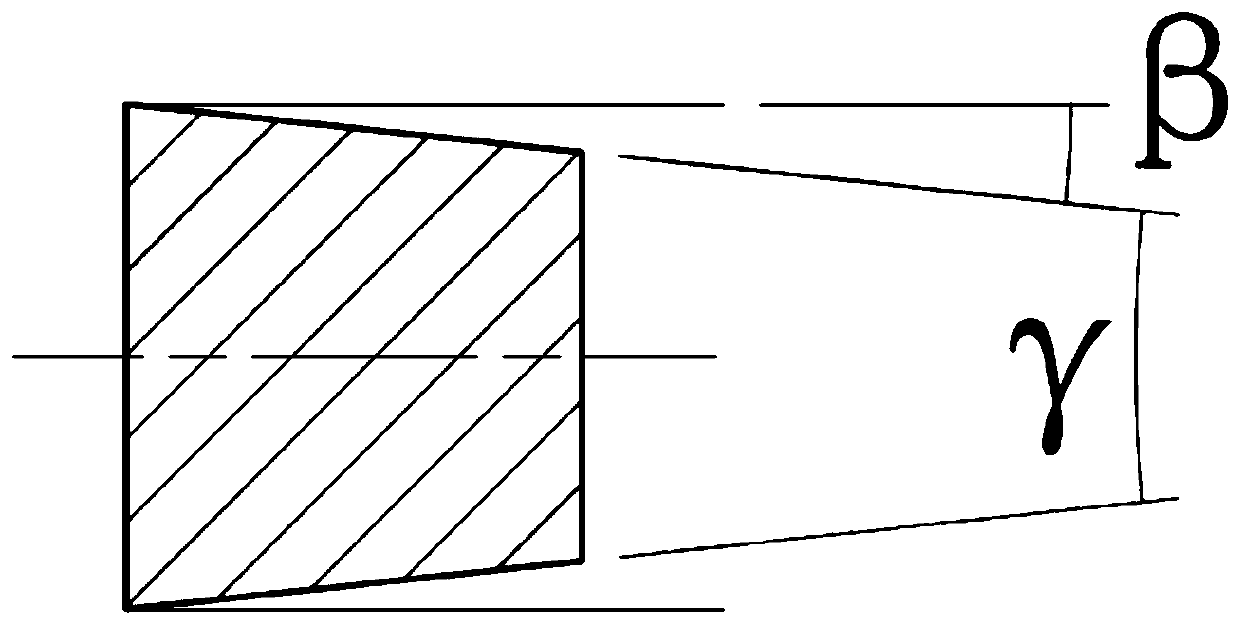

[0022] The present invention provides a method for machining inverted bevel teeth with variable pressure angle hobs, that is, using the existing method for machining inverted bevel teeth with variable pressure angle hobs, specifically: recalculate the new root cone angle during processing, according to The calculated root taper angle adjusts and debugs the movement path of the machine tool shaft, thereby changing the angle between the hob moving path line and the gear center line, and completing the machining of the inverted bevel gear. The root cone angle calculation method of variable pressure angle hob processing inverted bevel gears has no relevant literature documents at present. According to the analysis, calculation, derivation and verification of the problems encountered by the applicant in actual processing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com