Electrified operation robot remote operator training system and method based on point cloud

A technology for live work and personnel training. It is used in manipulators, program-controlled manipulators, and manufacturing tools. It can solve problems such as mechanical arm damage and poor vision, and achieve the effects of increasing speed, improving effectiveness, and reducing quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The point cloud-based remote operator training system for a live working robot of the present invention includes a depth camera, an industrial computer, and a main manipulator remote control lever with a force feedback function connected thereto, and an auxiliary mechanical arm remote control lever with a force feedback function such as figure 1 As shown, it is the Geomagic Touch six-dimensional tactile input and output device, which can provide the operator with a sense of force presence.

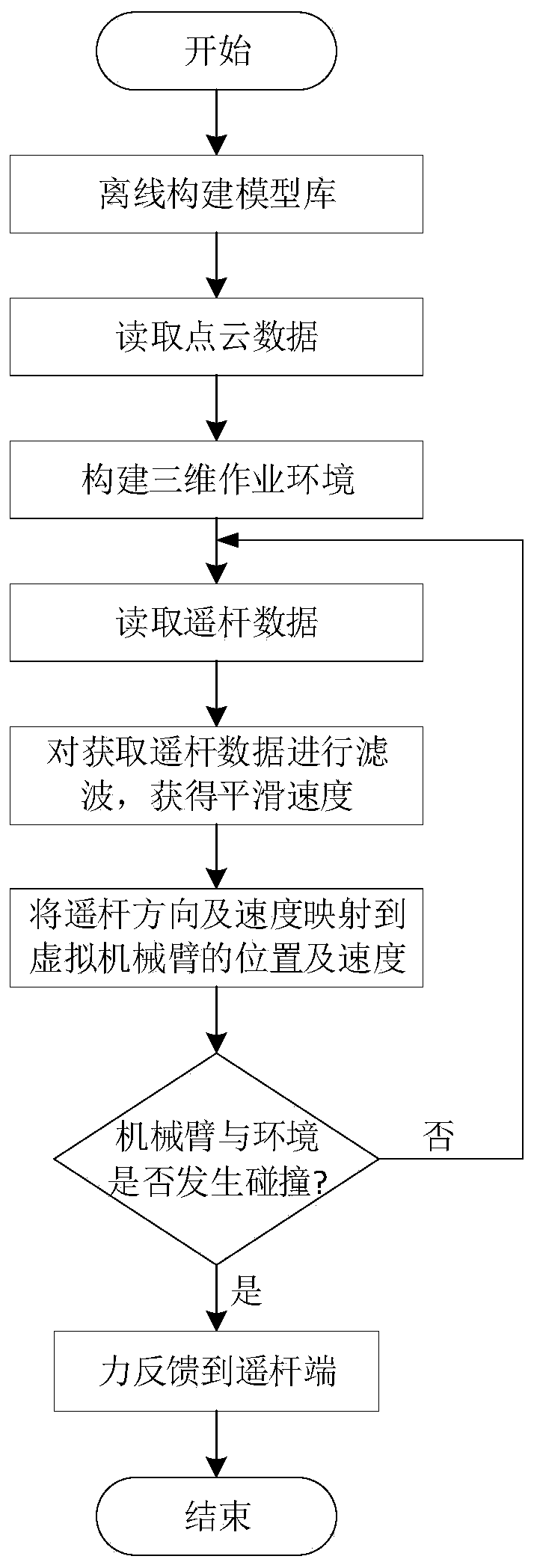

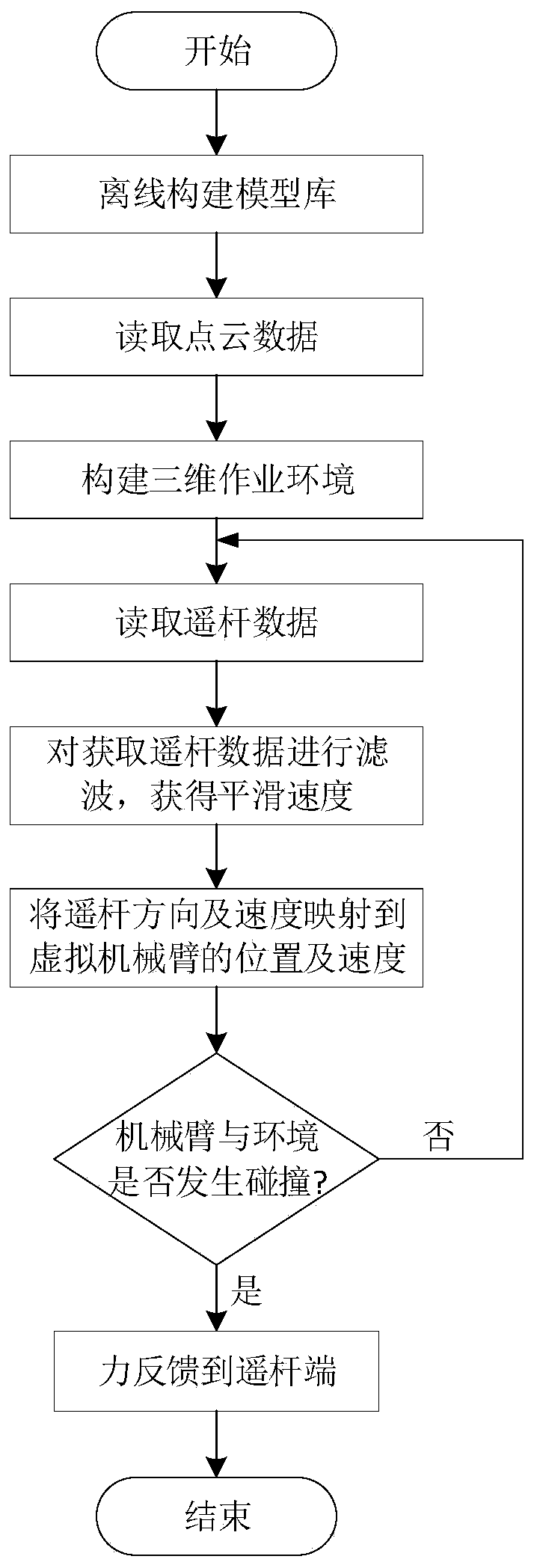

[0016] The depth camera is used to collect point cloud information of the actual working environment, and the industrial computer is used to establish a virtual working environment based on the point cloud information, including the virtual main manipulator, virtual auxiliary manipulator and other objects in the virtual environment, with force feedback The functional main manipulator remote control lever is used to control the movement of the virtual main manipulator, and the auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com