Rubber band binding device of plastic bag

A strapping device and plastic bag technology, applied in the direction of strapping objects, strapping materials, packaging/bundling items, etc., can solve the problems of easy sagging, bending, folding down, rebound expansion of plastic bags, and easy loosening of plastic bags, etc., to achieve Saves the cost of binding, is not easy to break, and has the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

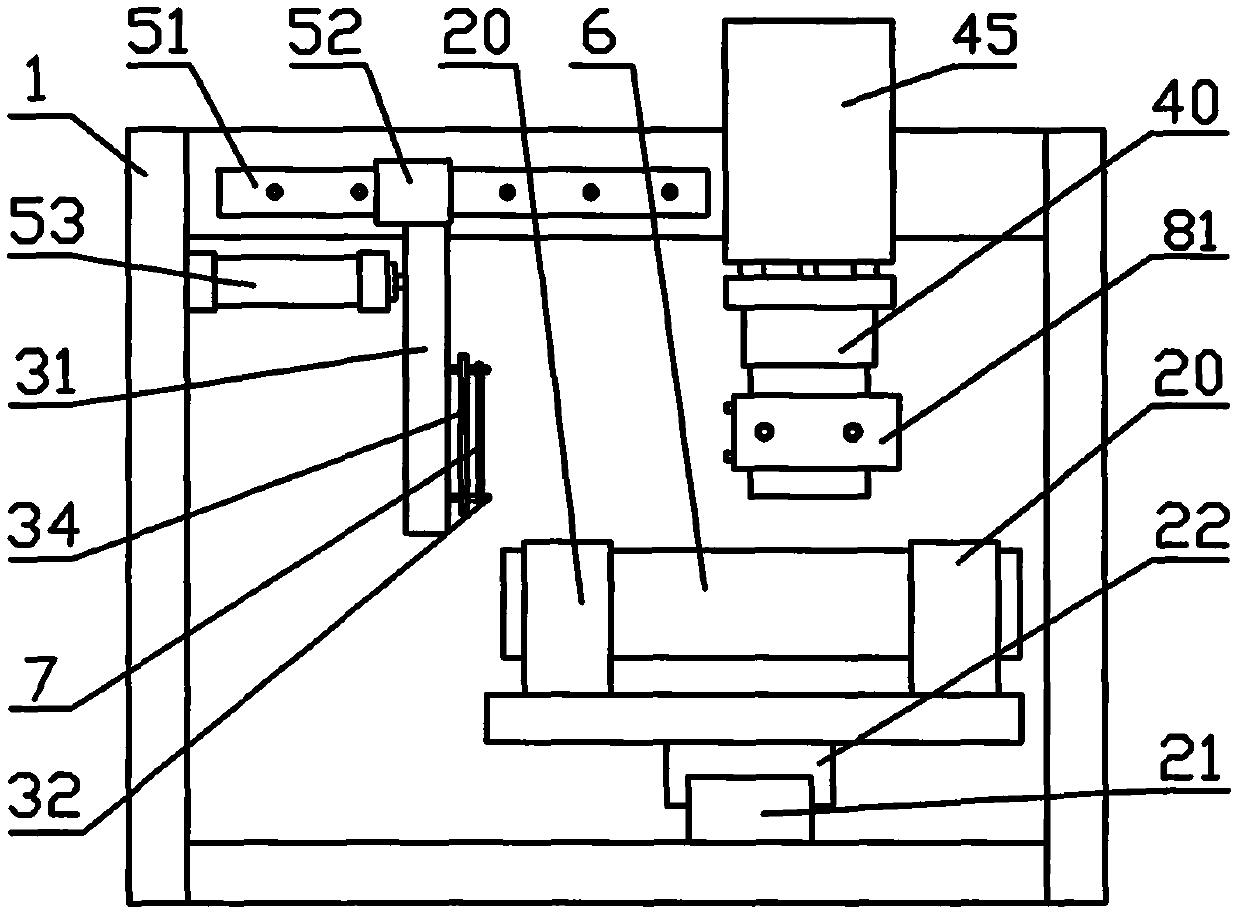

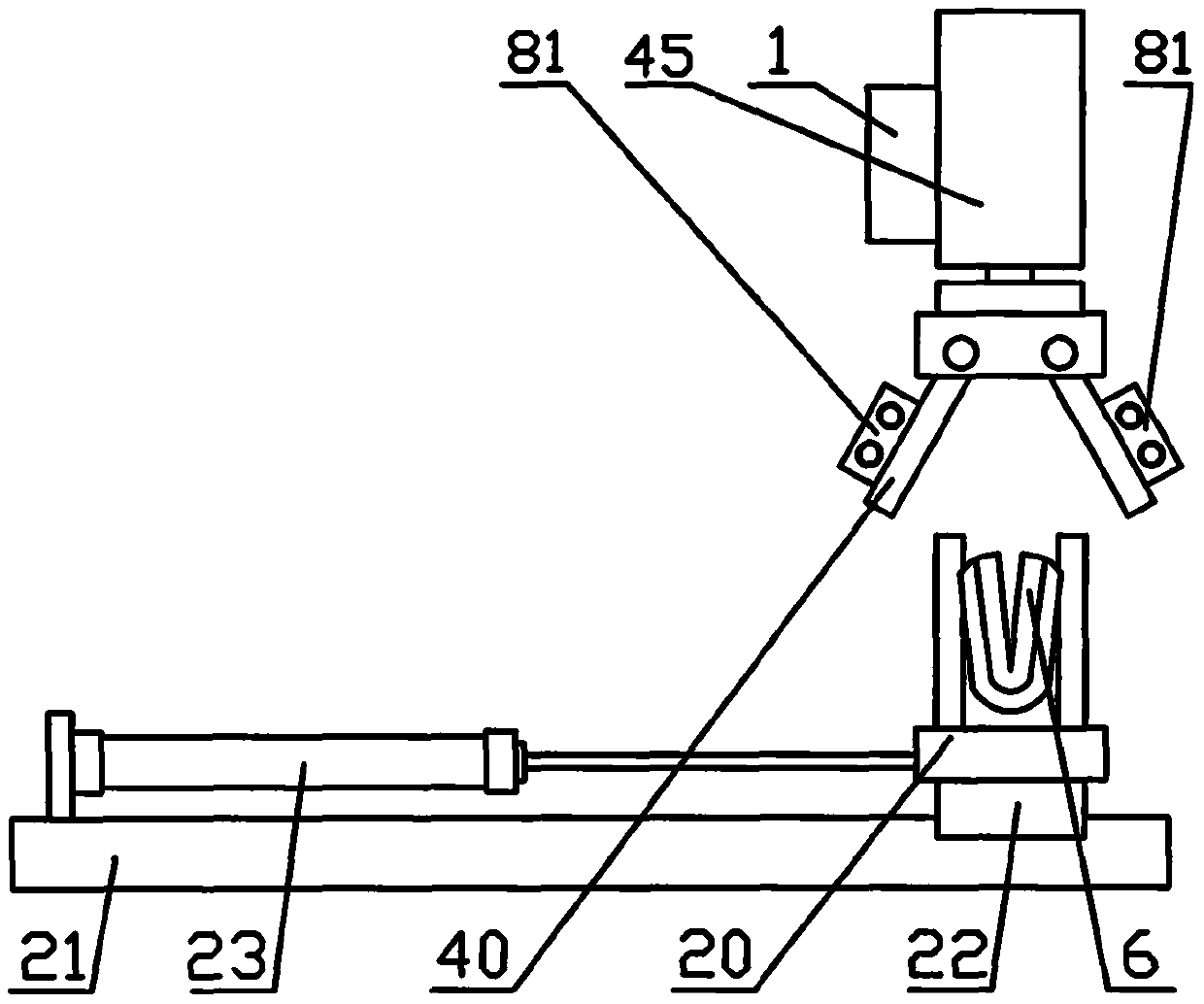

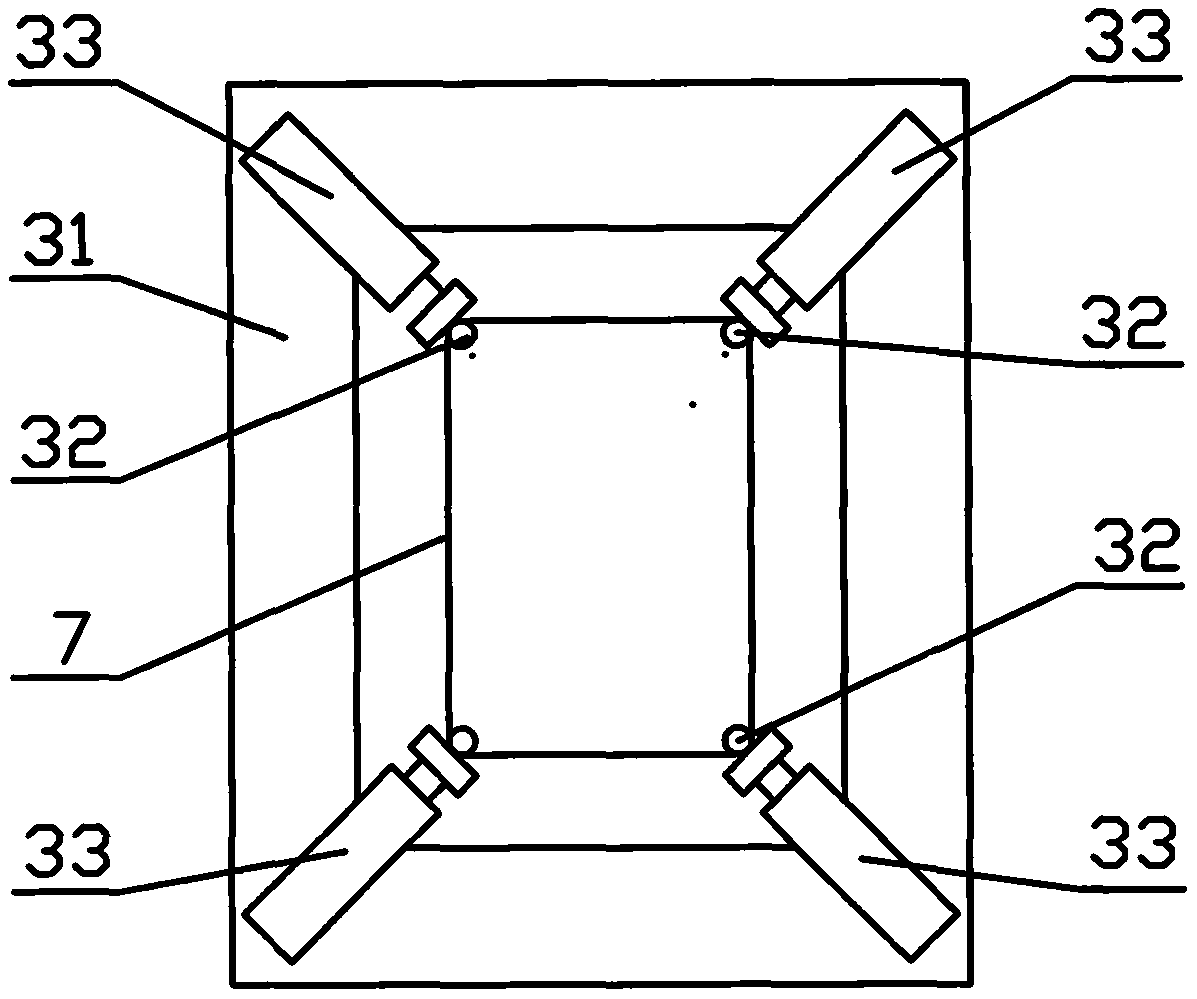

[0034] Embodiment one, such as Figure 1 to Figure 6 Shown: the relative movement mechanism 5 of embodiment one comprises guide rail 51, slide block 52, cylinder 53; A guide rail 51 is installed on the upper side of frame 1, and strapping mechanism 3 is slidably installed through slide block 52 below guide rail 51, in A cylinder 53 is connected between the strapping mechanism 3 and the frame 1; when the cylinder 53 works, the strapping mechanism 3 can be driven to perform a reciprocating linear motion relative to the bag clamping manipulator 40. Described binding mechanism 3 comprises support 31, strut 32, stretches out cylinder 33, as image 3 Shown: a square support 31 is set, and the middle part of the support 31 is provided with a square opening for enabling the plastic bag 6 to pass through; A strut 32 is respectively installed on the cylinder rod of 33. Suspended outward clamping bag mechanism 4 is a kind of bag clamping manipulator 40; Telescopic rod mechanism 8 is a ...

Embodiment 2

[0036] Embodiment two, such as Figure 8 , Figure 9 , Figure 10 Shown: the main difference of embodiment two is that the plastic bag feeding mechanism 2 of embodiment two is made of chain drive mechanism 24 and U-shaped clip 25, and telescopic rod mechanism 8 is made of square rail and slide block 84, cylinder 85. Such as Figure 8 Shown: a slide block 84 and a cylinder 85 are respectively installed on both sides of the bag clamping manipulator 40, and a wide-body square rail 83 is slidably installed on the slide block 84 respectively, so that the cylinder rod of the cylinder 85 is connected with the square rail 83 respectively, Described square rail 83 is a kind of wide body square rail, is exactly a kind of in fact. Such as Figure 9 Shown: the plastic bag delivery mechanism 2 of embodiment two comprises chain transmission mechanism 24 and U-shaped clip 25, and the plastic bag delivery mechanism that the embodiment two is made of chain transmission mechanism and U-shap...

Embodiment 3

[0039] Embodiment three, such as Figure 10 , Figure 11 , Figure 12 Shown: the main difference between the third embodiment and the first embodiment is that the plastic bag feeding mechanism 2 includes a turning frame 26, a turning part 27, a slider 22, a guide rail 21, and a cylinder 23. In the initial state, the turning frame 26 is Upright, that is, the opening of the overturning frame 26 faces upwards. When the plastic bag 6 is folded in the overturning frame 26, it is in a U-shaped upright state. When the overturning part 27 drives the overturning frame 26 to turn over about 90 degrees, it is formed Figure 11 In the state shown, the above-mentioned embodiment of the plastic bag feeding mechanism 2 has been disclosed in reference document 5, and reference can be made to a utility model patent entitled a packaging bag transfer device with the authorized announcement number CN207972864U. The plastic bag feeding mechanism of the third embodiment can directly transport the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com