Fabric elasticity reducing printing binder and preparation method thereof

A glue and elastic technology, applied in the field of clothing processing, can solve the problem of less clothing, and achieve the effects of bright colors, easy cleaning, reduced stretch and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

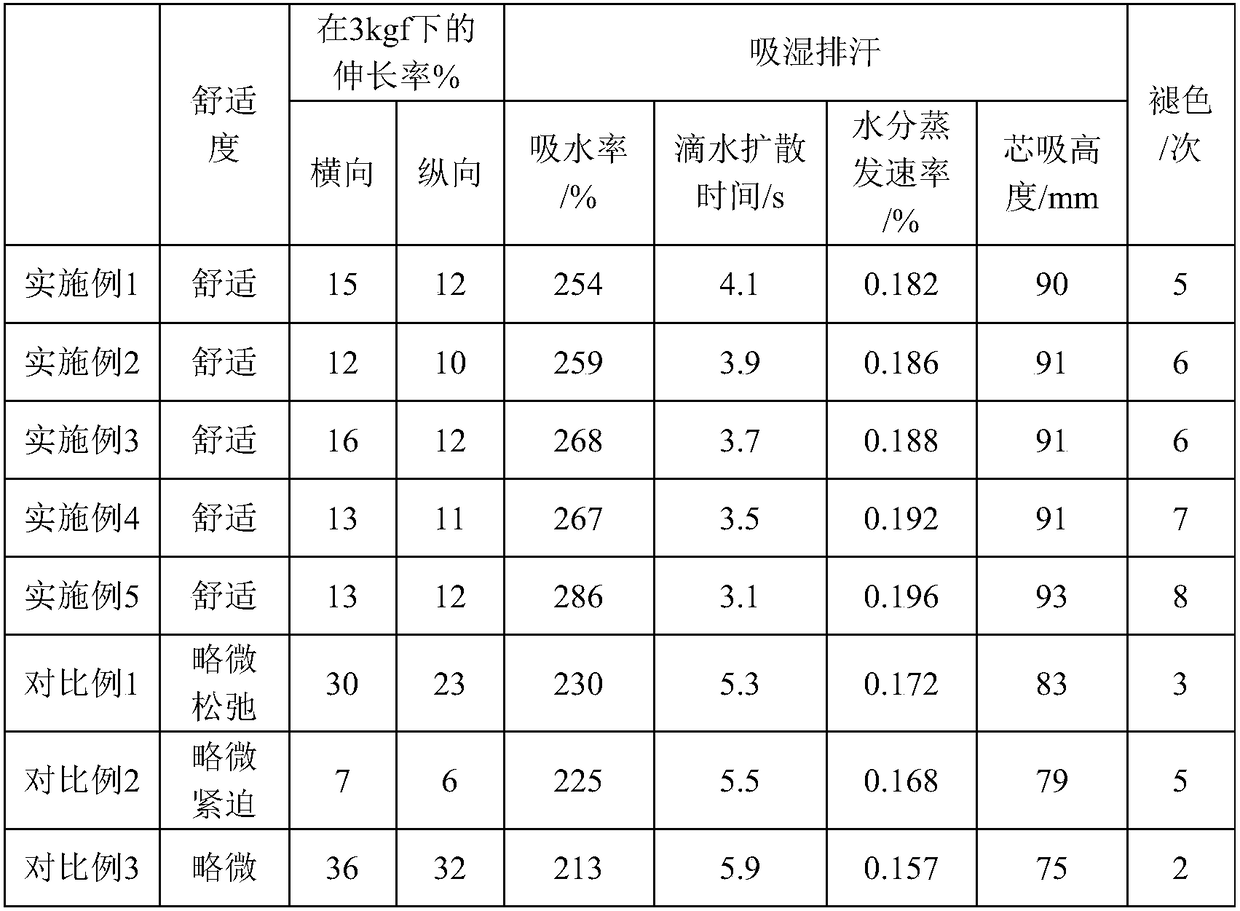

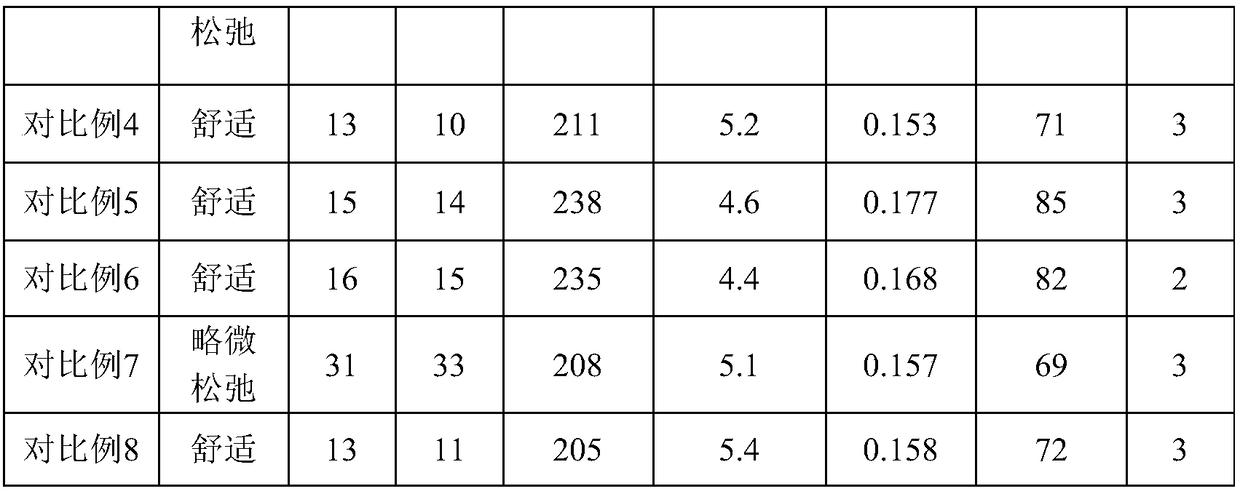

Examples

preparation example Construction

[0047] The second aspect of the present invention provides a method for preparing component A. The steps include: adding a certain amount of silicic acid gel, zinc oxide, and vulcanization accelerator into the dispersion tank, and adding hardener and anti-aging agent in sequence while stirring , Thinner, after adding, stir for 10-20 minutes until it is completely uniform, and pack it.

[0048]The inventors of the present application have found that the printing paste provided by the application can perform the function of compacting and compressing the fabric, so that the fabric can be applied to functional clothing. The inventor speculates that the possible reason is that the A component is at room temperature. When it is printed on nylon and polyester fabrics, it will interact with the fabric, so that the opening degree and resilience of the fabric will be significantly reduced.

[0049] Hydroxy-terminated polydimethylsiloxane

[0050] The hydroxyl-terminated polydimethyl...

Embodiment 1

[0073] Embodiment 1 provides a printing glue for weakening the elasticity of fabrics, including component A and component B, wherein component A is a silicone glue, and component B is a water-based resin glue.

[0074] The raw materials for the preparation of component A include: silicic acid gel, zinc oxide, vulcanization accelerator, anti-aging agent, diluent, and hardener.

[0075] In parts by weight, the raw materials for the preparation of component A include: 70 parts of silicic acid gel, 1 part of zinc oxide, 1 part of vulcanization accelerator, 1 part of anti-aging agent, 5 parts of thinner and 1 part of hardener.

[0076] The raw materials for the preparation of the B component include: hydroxyl-terminated polydimethylsiloxane, color paste, curing agent, and water.

[0077] In parts by weight, the raw materials for the preparation of component B include: 50 parts of hydroxyl-terminated polydimethylsiloxane, 35 parts of color paste, 5 parts of curing agent, and 20 part...

Embodiment 2

[0089] Embodiment 2 provides a printing glue for weakening fabric elasticity, including component A and component B, wherein component A is a silicone glue, and component B is a water-based resin glue.

[0090] The raw materials for the preparation of component A include: silicic acid gel, zinc oxide, vulcanization accelerator, anti-aging agent, diluent, and hardener.

[0091] In parts by weight, the raw materials for the preparation of component A include: 90 parts of silicic acid gel, 5 parts of zinc oxide, 3 parts of vulcanization accelerator, 5 parts of anti-aging agent, 8 parts of diluent and 3 parts of hardener.

[0092] The raw materials for the preparation of the B component include: hydroxyl-terminated polydimethylsiloxane, color paste, curing agent, and water.

[0093] In parts by weight, the raw materials for the preparation of component B include: 60 parts of hydroxyl-terminated polydimethylsiloxane, 40 parts of color paste, 7 parts of curing agent, and 30 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com