Debugging method of cargo oil pump system

A debugging method and cargo oil pump technology, applied in pump testing, pump control, liquid variable capacity machinery, etc., can solve the problems of unguaranteed debugging quality and low utilization rate of man-hours, and improve the utilization rate of man-hours and commissioning quality Improvement, the effect of reasonable quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

[0022] This embodiment provides a debugging method for a cargo oil pump system. The cargo oil pump system includes a relay protection device for implementing various protections for the cargo oil pump. Wherein, the relay protection device includes modules such as a processor and a display.

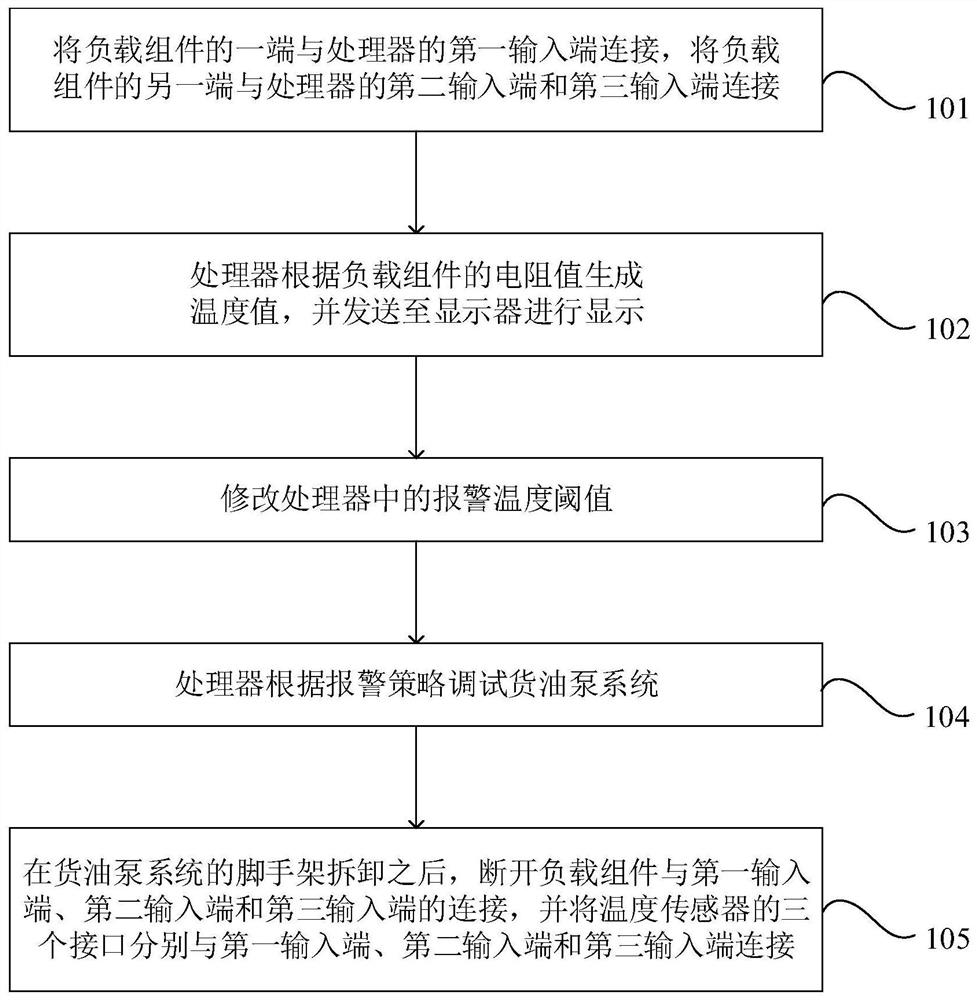

[0023] Such as figure 1 As shown, the debugging method of this embodiment includes the following steps:

[0024] Step 101, connect one end of the load component to the first input end of the processor, and connect the other end of the load component to the second input end and the third input end of the processor.

[0025] Wherein, the first input end, the second input end and the second input end are used for connecting the temperature sensor. Step 101, that is, when debugging, use the load component to simulate the internal circuit of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com