A Highly Stable Length Telescopic Modular Quartz Temperature Sensor Using Non-Contacting Electrodes

A temperature sensor, non-contact technology, applied in the field of sensors, can solve problems affecting thermal hysteresis characteristics, repeatability and long-term stability, and affect the long-term stability of resonant quartz temperature sensors, etc., to achieve good long-term stability and improve long-term stability Consistent and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

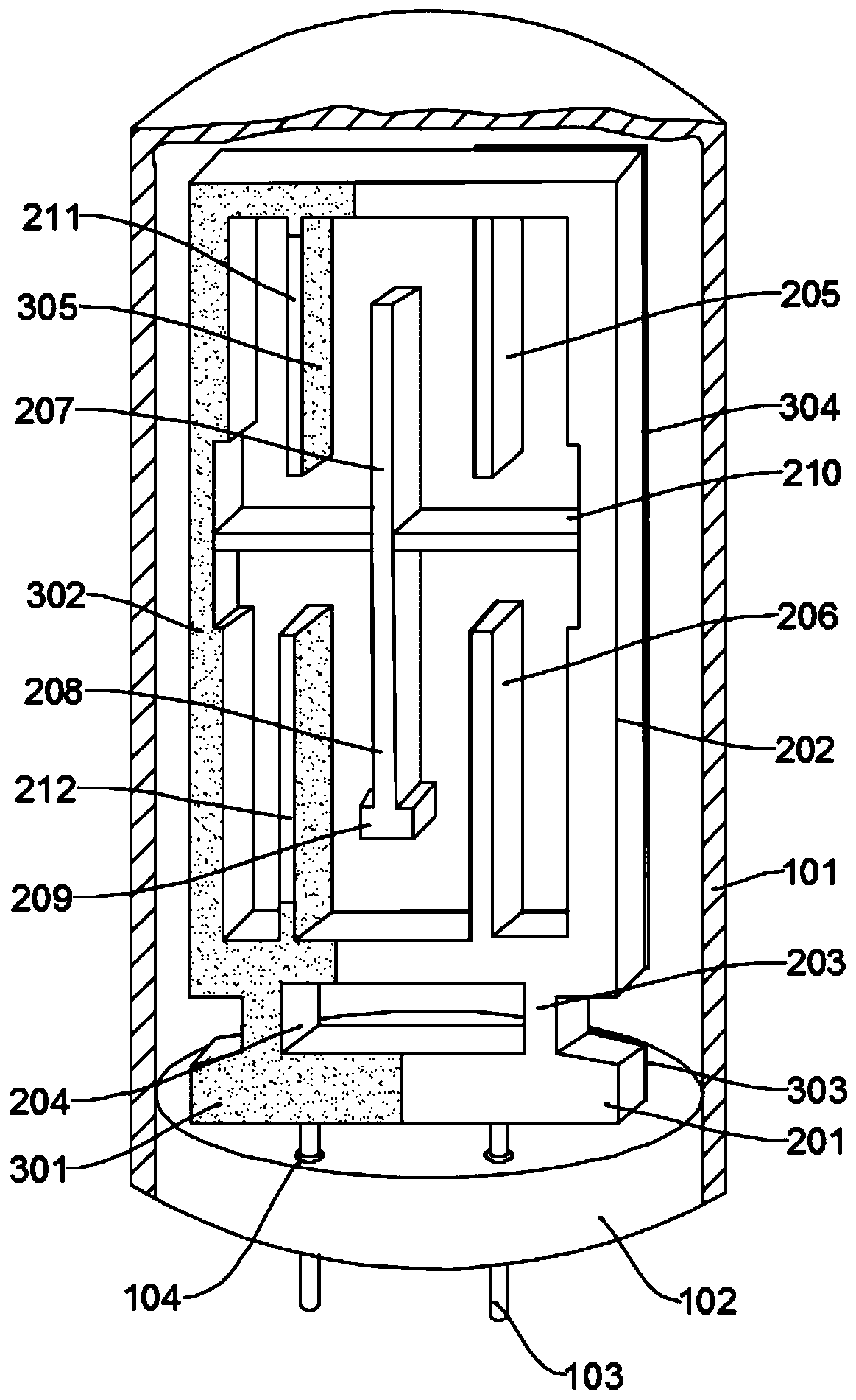

[0053] see figure 1, in the embodiment of the present invention, the m comb-tooth pieces include the first comb-tooth piece 205, the second comb-tooth piece 206, the third comb-tooth piece 211 and the fourth comb-tooth piece 212, and the n resonant arms include the first comb-tooth piece The resonant arm 207 and the second resonant arm 208, that is, in this embodiment, m=4 and n=2. The first resonant arm 207 and the second resonant arm 208 are arranged at the center of the support frame 202 and connected to the side inner wall of the support frame 202 through the support pieces 210 on both sides. The three comb-toothed pieces 211 are connected to the upper inner wall of the supporting frame 202 and are symmetrically distributed on both sides of the first resonant arm 207, and the second comb-toothed piece 206 and the fourth comb-toothed piece 212 are connected to the lower side of the supporting frame 202. The inner wall is symmetrically distributed on both sides of the secon...

Embodiment 2

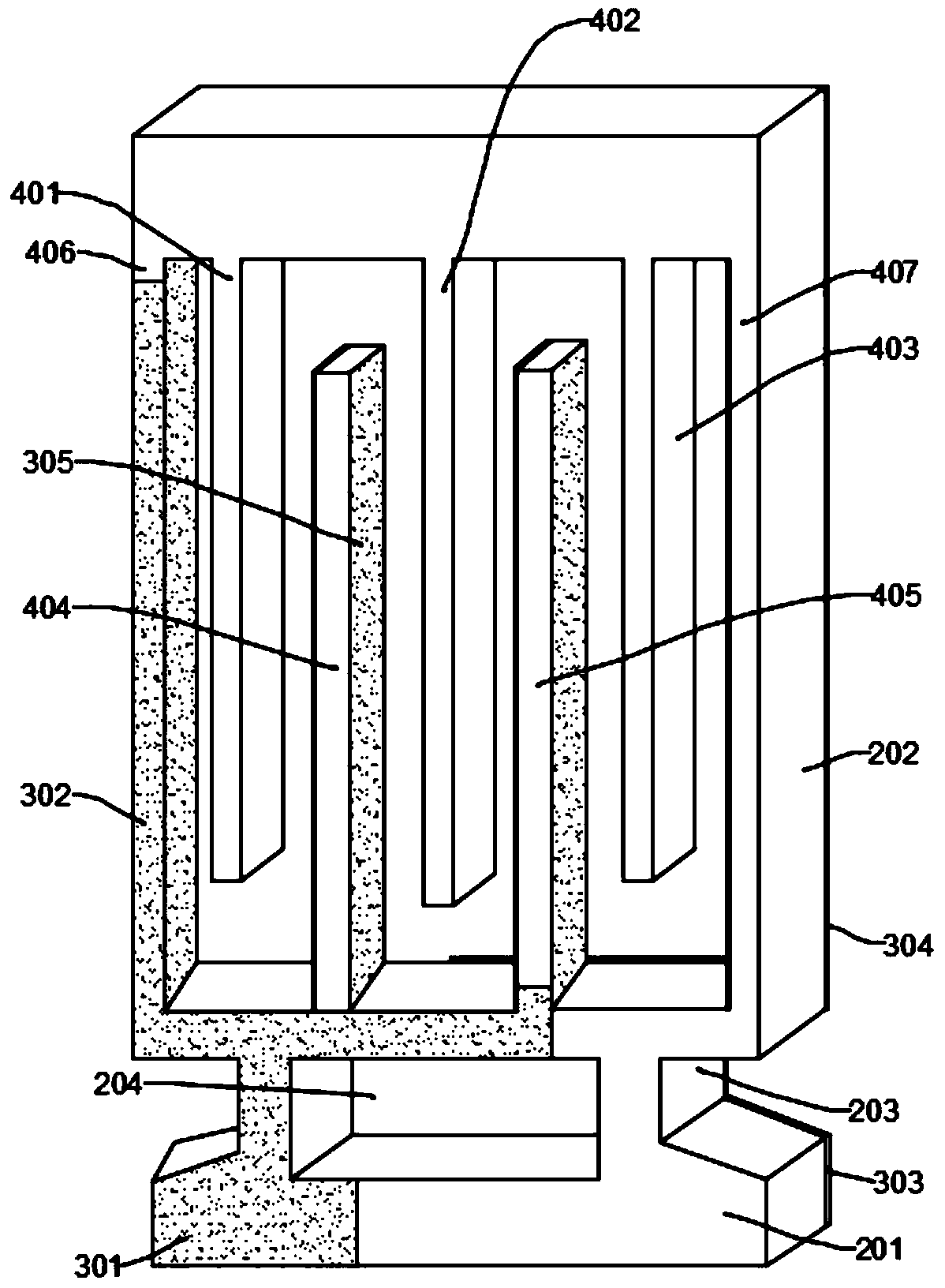

[0058] see figure 2 , in the embodiment of the present invention, the m comb-tooth pieces include the eighth comb-tooth piece 404, the fifth comb-tooth piece 405, the sixth comb-tooth piece 406 and the seventh comb-tooth piece 407, and the n resonant arms include The third resonant arm 401, the fourth resonant arm 402 and the fifth resonant arm 403, that is, in this embodiment, the m=4, n=3; the third resonant arm 401, the fourth resonant arm 402 and the fifth resonant arm The resonant arm 403 is sequentially connected to the upper inner wall of the supporting frame 202, and the eighth comb-toothed piece 404, the fifth comb-toothed piece 405, the sixth comb-toothed piece 406 and the seventh comb-toothed piece 407 are sequentially connected to the supporting frame at intervals The lower inner wall of the body 202 is interlaced with the third resonant arm 401, the fourth resonant arm 402 and the fifth resonant arm 403;

[0059] The bus electrodes include a first bus electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com