High-resistance buffer layer using gan-based narrow well multiple quantum well structure and preparation method

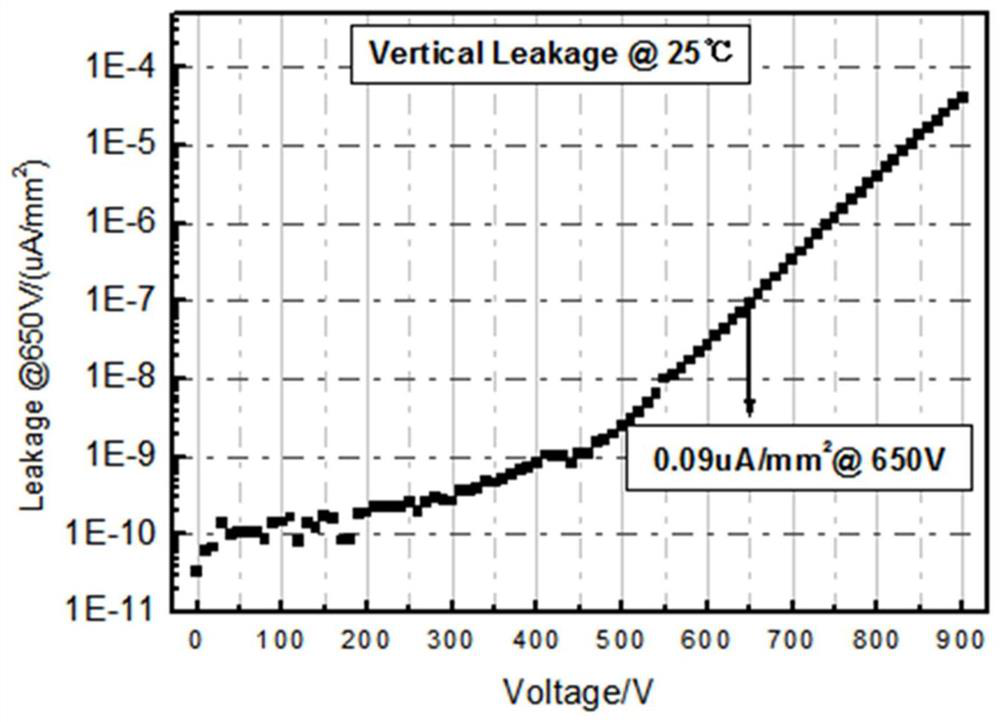

A multi-quantum well structure and high-resistance buffer layer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of epitaxial layer quality deterioration, mobility decline, poor repeatability, etc., and achieve high resistance value, the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the specific drawings and embodiments.

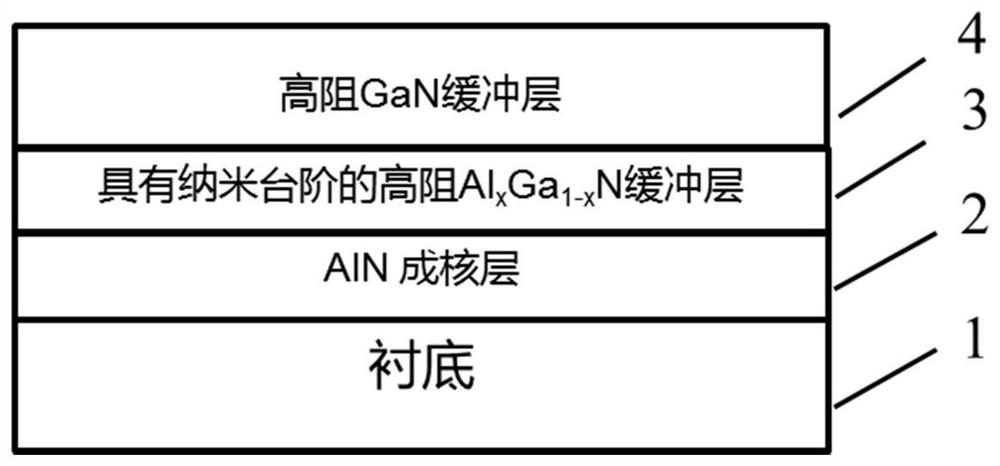

[0026] refer to Figure 1-2 , a high-resistance buffer layer utilizing a GaN-based narrow well multiple quantum well structure, comprising a Si or SiC substrate 1, an AlN nucleation layer 2, Al a Ga 1-aN-based narrow well multiple quantum well high resistance buffer layer 3 and high resistance GaN buffer layer 4:

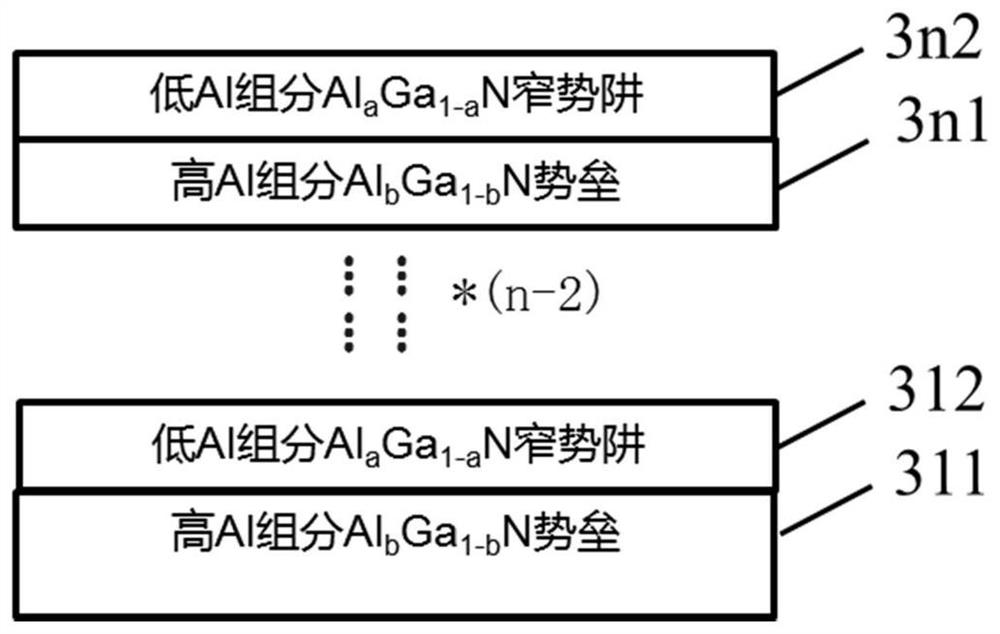

[0027] the Al a Ga 1-a The N-based narrow well multiple quantum well high resistance buffer layer 3 includes a plurality of quantum well periods, and each quantum well period further includes stacked low Al composition Al a Ga 1-a N narrow well layer 311...3n1, high Al composition Al b Ga 1-b N barrier layers 312...3n2, the number of multi-quantum periods is 5-100; the high Al composition Al b Ga 1-b The thickness of the N barrier layer is larger than that of the low Al composition Al a Ga 1-a N thickness of the narrow well layer.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap