pcba manufacturing service method

A technology for manufacturing services and materials, applied in manufacturing computing systems, printed circuit manufacturing, instruments, etc., can solve problems such as PCBA's inability to manage data traceability, and the inability to troubleshoot quality hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

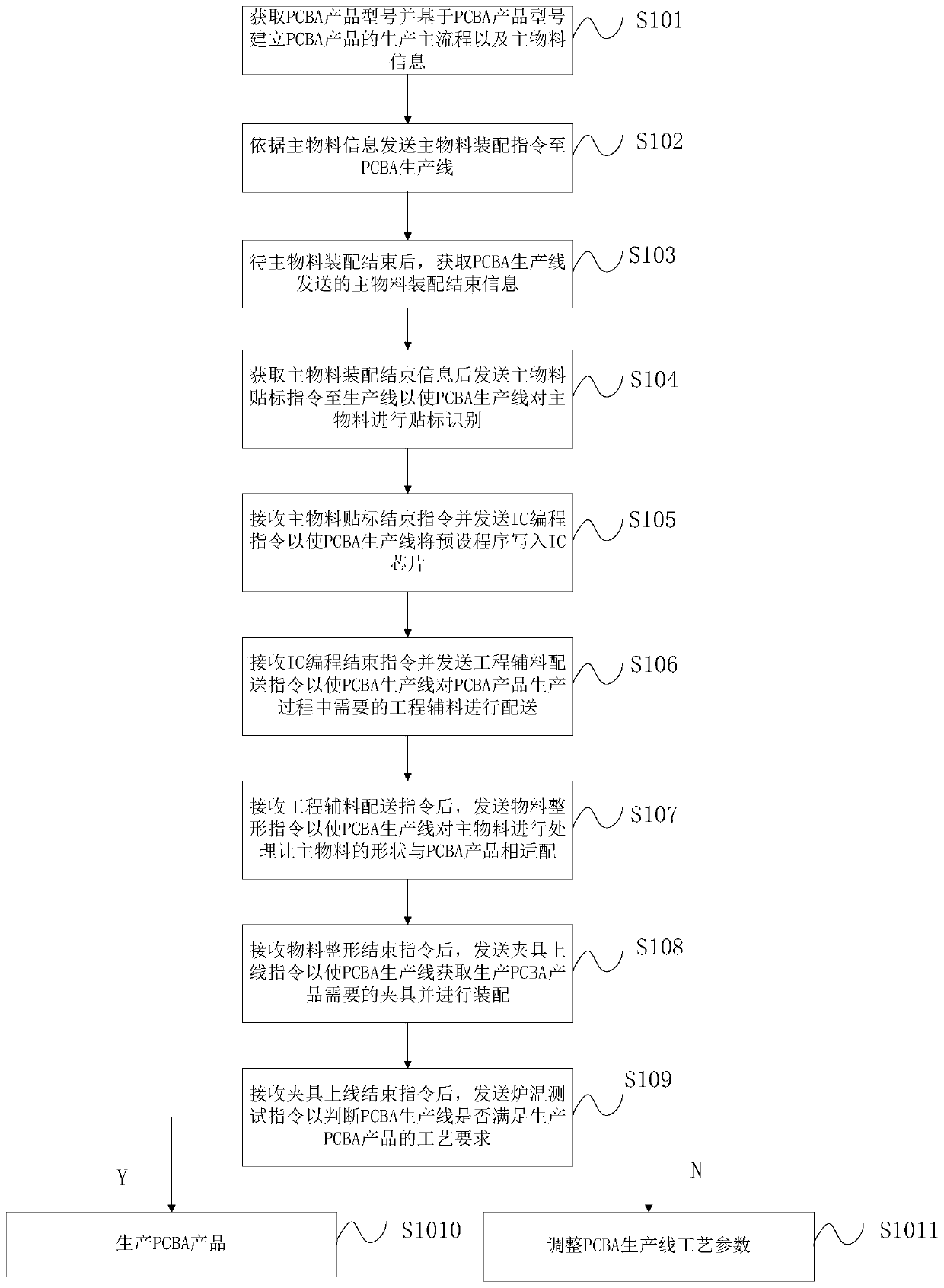

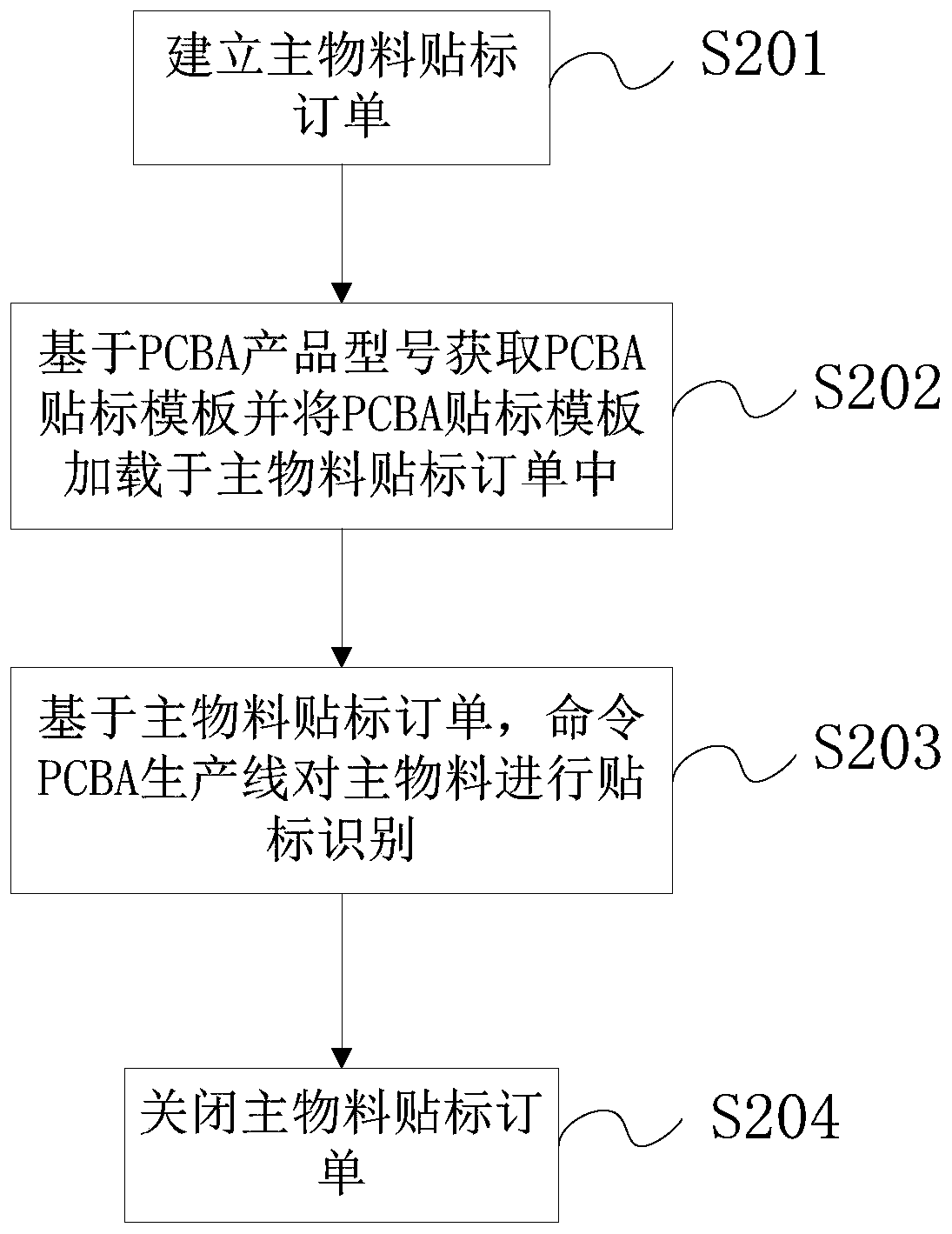

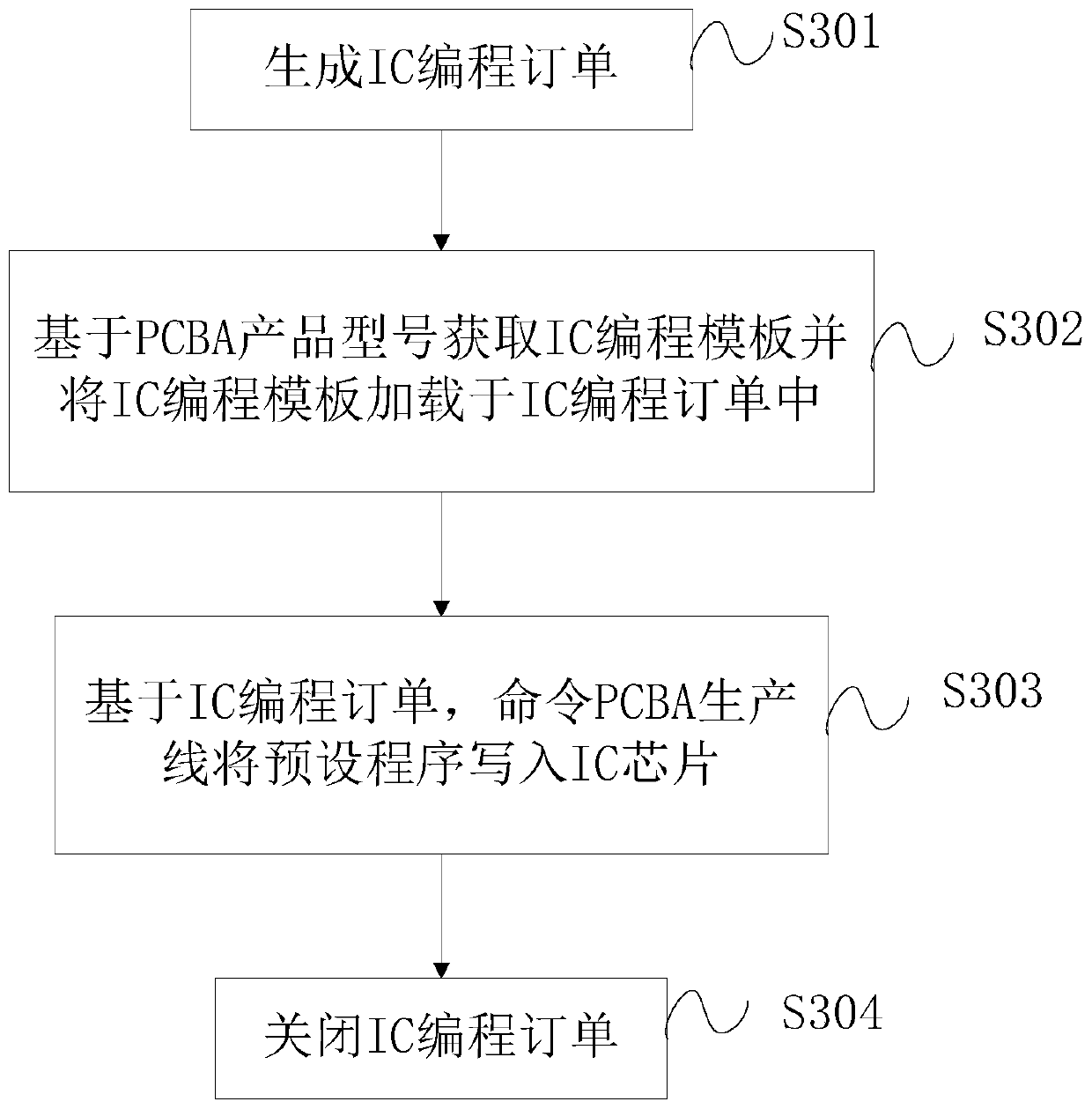

[0078] Embodiment 1 of the present invention provides a PCBA manufacturing service method. In the PCBA manufacturing process, it can be roughly divided into the following steps, printing, patching, plug-in, welding, etc. The present invention mainly carries service sub-processes in each main process. In order to realize the intelligent production and manufacturing of PCBA, in this embodiment, the MES system is installed on the server side, and the PCBA production line control terminal is equipped on the PCBA production line side, which can control the operation of the PCBA production line. Specifically, such as figure 1 shown, including the following steps:

[0079] S101: Obtain the PCBA product model and establish the main production process and main material information of the PCBA product based on the PCBA product model;

[0080] The main purpose of S101 is to build the main process of PCBA production. Specifically, the above server obtains the PCBA product model, and the a...

Embodiment 2

[0136] Such as Figure 8 As shown, in order to further optimize the service process of PCBA production, the second embodiment of the present invention discloses the steps of detecting the first PCBA product produced by PCBA when PCBA products are produced in batches;

[0137] Optionally, perform S801: the step of testing the first PCBA product produced by the PCBA production line and judging whether the first PCBA product is qualified;

[0138] Further, the above steps of S801 include:

[0139] S802: Establish a first-piece inspection order;

[0140] S803: Obtain the first article inspection template based on the PCBA product model and load the first article inspection template into the first article inspection order;

[0141] S804: Based on the first piece inspection order, order the first PCBA product produced by the PCBA production line to be tested;

[0142] Preferably, the server side establishes the first article inspection order and obtains the first article inspecti...

Embodiment 3

[0146] What embodiment three provides is the possible implementation manner that PCBA production line and PCBA product are monitored during the production process;

[0147] During the PCBA production process, execute: S901: When the preset time is reached or the number of PCBA products produced reaches the preset number, inspect the PCBA production line and / or inspect the PCBA products produced;

[0148] In one embodiment of the present invention, as Figure 9 As shown, the above steps of S901 include: S902: Arriving at the preset time or the preset number of PCBA products produced, and establishing an inspection order for the PCBA production line;

[0149] S902: Obtain the PCBA production line inspection template based on the PCBA product model and load the PCBA production line inspection template into the PCBA production line inspection order;

[0150] S903: Based on the PCBA production line order, detect the process parameters of the PCBA production line and determine whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com